Solid phase microextraction fiber for polycyclic aromatic hydrocarbon enriching detection and manufacturing method thereof

A technology for polycyclic aromatic hydrocarbons and fiber extraction, applied in the field of pollutant detection, can solve the problems of poor high temperature resistance, etc., and achieve the effect of not easy to fall off, uniform coating, and firm synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

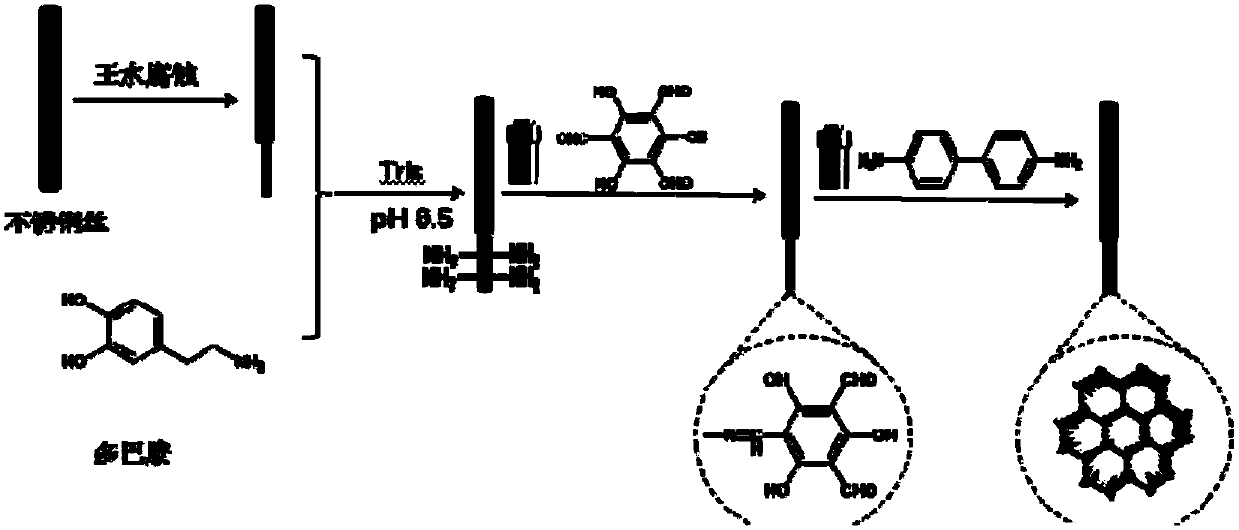

[0046] Embodiment 1: The manufacture method of the solid-phase microextraction device based on polydopamine-TpBD composite coating

[0047] Corrode a 17cm-long stainless steel wire in newly prepared aqua regia for about 30 minutes, and the corrosion length is 3cm, and then immerse it in a 2mg / mL dopamine solution with a pH=8.5Tris-HCL, stir it in a water bath at 35°C for 12 hours, and then Rinse the surface with distilled water and oven dry at 80°C for 12 hours. Place the prepared polydopamine stainless steel wire in a reaction kettle of 63mg 1,3,5-trimethylresorcinol solution dissolved in 4mL mesitylene, and react at 80°C for 4 hours, then add 4mL dioxane A solution of 83mg of benzidine dissolved in the ring was reacted at 120°C for 48 hours. After removal, the fibers were soaked in acetone for 3 days, soaked in ethanol for 1 day, and dried in vacuum. The solid-phase microextraction device was fabricated by using the stainless steel wire fiber with a composite layer instead...

Embodiment 2

[0048] Example 2: Optimization of enrichment conditions for the detection of polycyclic aromatic hydrocarbons in barbecued meat by solid-phase microextraction device

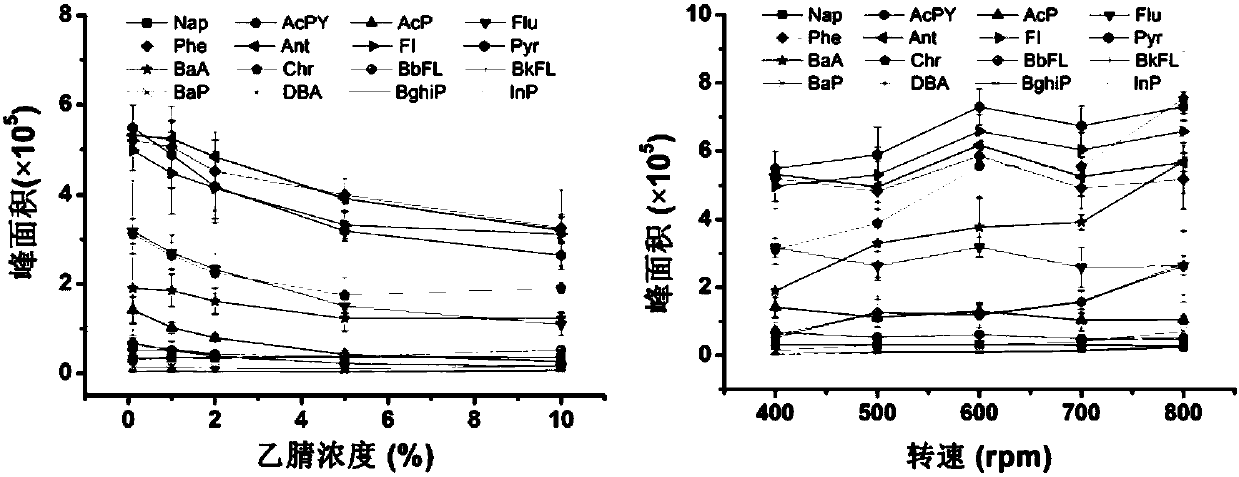

[0049] During solid-phase microextraction, the extraction temperature, organic solvent ratio, extraction time, solution pH, rotation speed and analysis time all have an impact on the extraction results. In this experiment, direct (immersion) extraction method was used to enrich PAHs in barbecued meat. The conditions were optimized, and the proportion of organic solvent, rotation speed, solution pH, extraction time and analysis time were respectively optimized. The enrichment conditions were optimized by using 100ppt PAH mixed standard solution. The organic solvent is acetonitrile, the optimal range is between 0.1%-10%, the rotation speed is 300rpm, the temperature is 40°C, pH=6, the enrichment time is 30min, and the analysis time is 5min; the optimal rotation speed range is between 300-700rpm, and the acetonitri...

Embodiment 3

[0050] Example 3: Solid-phase microextraction device is used for the detection of polycyclic aromatic hydrocarbons in barbecue

[0051] (1) Preparation of standard samples: Prepare polycyclic aromatic hydrocarbon standard solution with acetonitrile, and gradiently dilute to 100 ppb for use. The 16 PAHs are naphthalene, acenaphthylene, acenaphthylene, fluorene, phenanthrene, anthracene, fluoranthene, pyrene, benzo[a]anthracene, Benzo[b]fluoranthene, benzo[k]fluoranthene, benzo[a]pyrene, indeno[1,2,3-c,d]pyrene, dibenzo[a,h]anthracene and benzo[a]pyrene [g,h,i] perylene.

[0052] (2) Configuration of the enrichment solution: distilled water was used to prepare the enrichment solution, the proportion of organic solvent was 0.1%, and the total volume was 10 mL.

[0053] (3) Sample preparation: Add 10 mL of acetonitrile to 1 g of grilled mutton for ultrasonic extraction for 20 min, centrifuge at 10,000 rpm for 10 min, take the supernatant, add 10 mL of acetonitrile to the residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com