Preparation method of copper-zinc-tin-sulfide photoelectric film

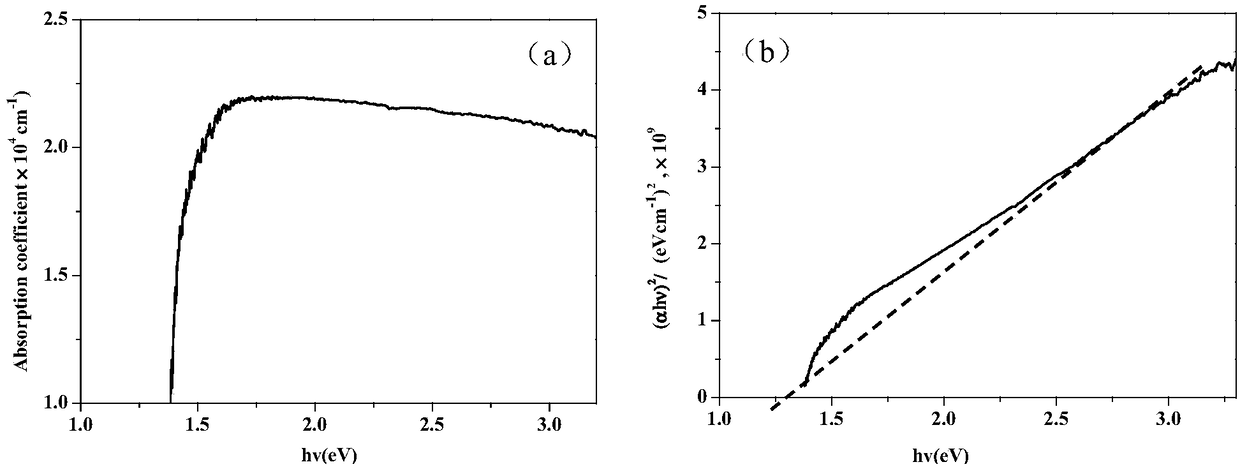

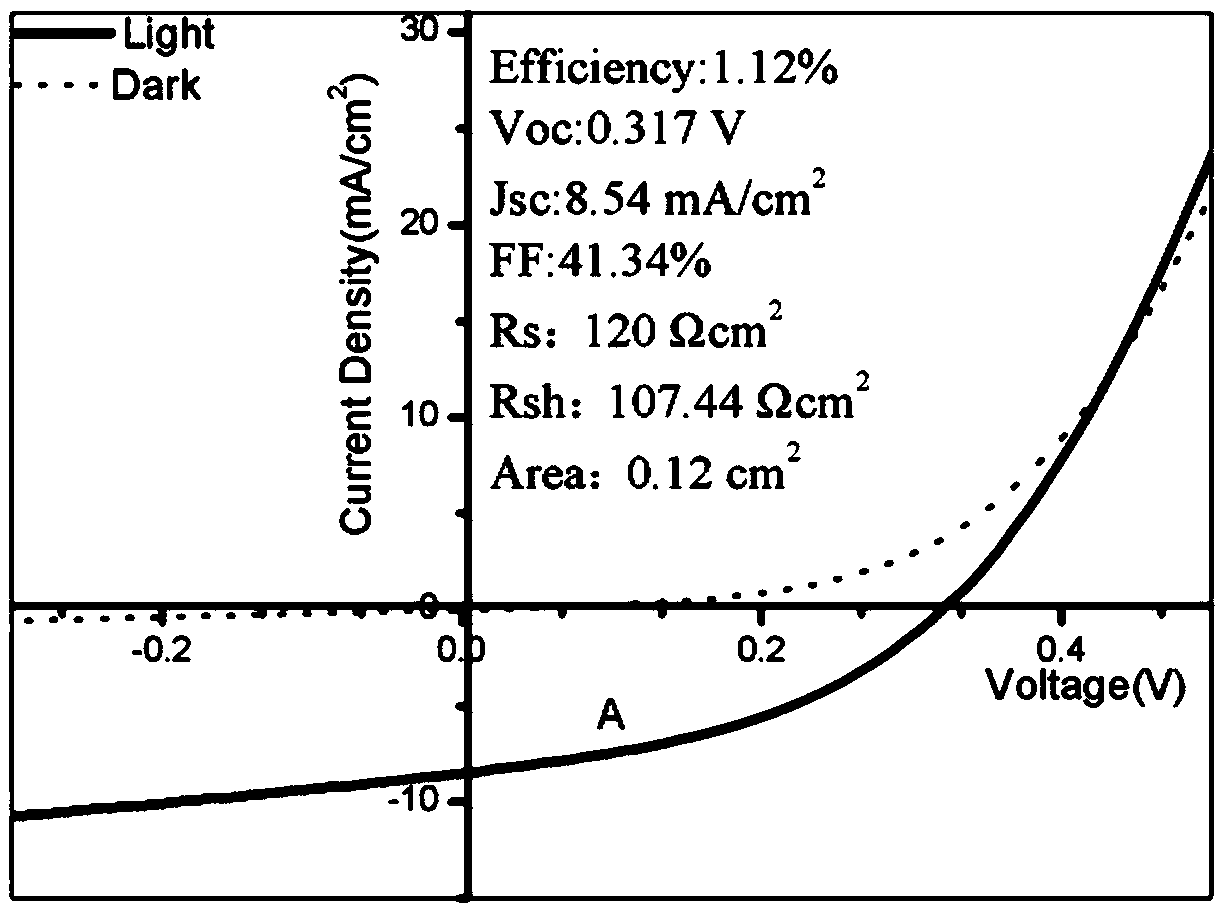

A photoelectric thin-film, copper-zinc-tin-sulfur technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of large particle size and low light absorption coefficient, and achieve the effects of low cost, high light absorption coefficient and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention discloses a method for preparing a copper-zinc-tin-sulfur photoelectric thin film, which specifically includes the following steps:

[0028] Step 1, mix copper sulfate, zinc sulfate, stannous sulfate and sodium hydroxide according to the mass concentration ratio of 2:1:1.5:1, add deionized water containing PVP, and adjust the pH value at 40-55°C 7 to 11, stand at this temperature for 1.5 to 2 hours, wash and filter to separate to obtain a composite precipitate;

[0029] Wherein, the addition amount of PVP is 0.1%-2% of the mass of deionized water. The mass concentration of copper sulfate is 12-60g / L, the mass concentration of zinc sulfate is 8-35g / L, the mass concentration of stannous sulfate is 8-40g / L, and the mass concentration of sodium hydroxide is 10-35g / L.

[0030] Step 2, vacuum-drying the composite precipitate, placing it in a tubular atmosphere furnace, and sintering at 450-700° C. for 0.5-4 hours to obtain composite oxide particles;

[0031] S...

Embodiment 1

[0038] Take mass concentration as 32g / L CuSO 4 , 16g / L ZnSO 4 , 21.5g / L SnSO 4 Mix with 16g / L NaOH, pour into deionized water containing PVP, wherein the added content of PVP is 0.5% of the mass of deionized water, adjust the pH of the solution to 9.5 at 40°C, and stand and age at this temperature for 2h, Filter and wash with deionized water and ethanol three times respectively to obtain mixed hydroxide precipitation, and the precipitation rates of copper, zinc and tin all reach more than 95%;

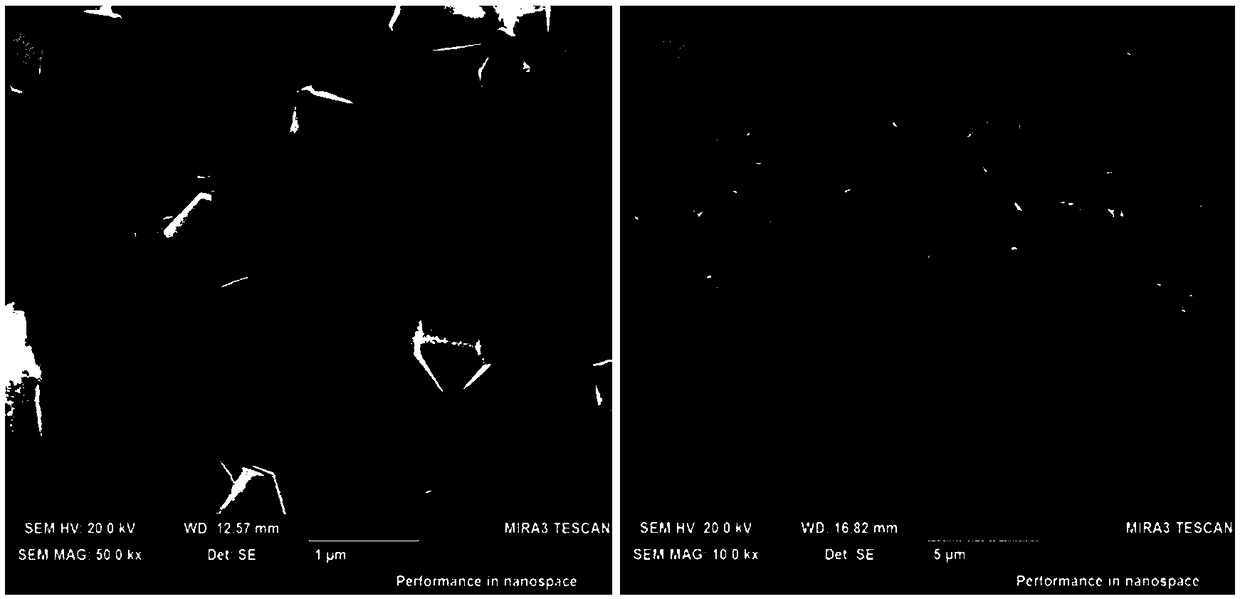

[0039] The mixed hydroxide precipitate obtained above is calcined at a high temperature in a tubular atmosphere furnace, the temperature is controlled at 550° C., and the holding time is 2 hours to obtain composite oxide particles, and the recovery rate of copper, zinc and tin reaches more than 98%. Take 1.5g of copper-zinc-tin composite oxide and disperse it in 30ml of ethanol, add methyl cellulose accounting for 1% of the ethanol mass and PVP accounting for 1% of the ethanol mass, ...

Embodiment 2

[0044] Take mass concentration as 16g / L CuSO 4 , 8g / L ZnSO 4, 8g / L SnSO 4 Mix with 10g / L NaOH, pour into deionized water containing PVP, wherein the added content of PVP is 0.1% of the mass of deionized water, adjust the pH of the solution to 8.5 at 55°C, and stand and age at this temperature for 2h, Filter and wash with deionized water and ethanol three times to obtain mixed hydroxide precipitates; the precipitation rates of copper, zinc and tin all reach more than 85%; the above mixed hydroxide precipitates are placed in a tubular atmosphere furnace for high temperature calcination, controlled The temperature is 480°C, the holding time is 1h, and the composite oxide particles are obtained, and the recovery rate of copper, zinc and tin reaches more than 88%. Weigh 1.5g of copper-zinc-tin composite oxide and add it to 20ml of ethanol, and add 0.2% The methyl cellulose and 0.2% PVP were ball milled for 7 hours at a speed of 450r / min, and after mixing evenly, they were ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com