Indium gallium nitride thin film on flexible transparent polyimide substrate and preparation method thereof

A technology of transparent polyimide and polyimide, applied in gaseous chemical plating, semiconductor/solid-state device manufacturing, coating, etc., can solve the problems of poor surface crystallization quality of polyimide substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

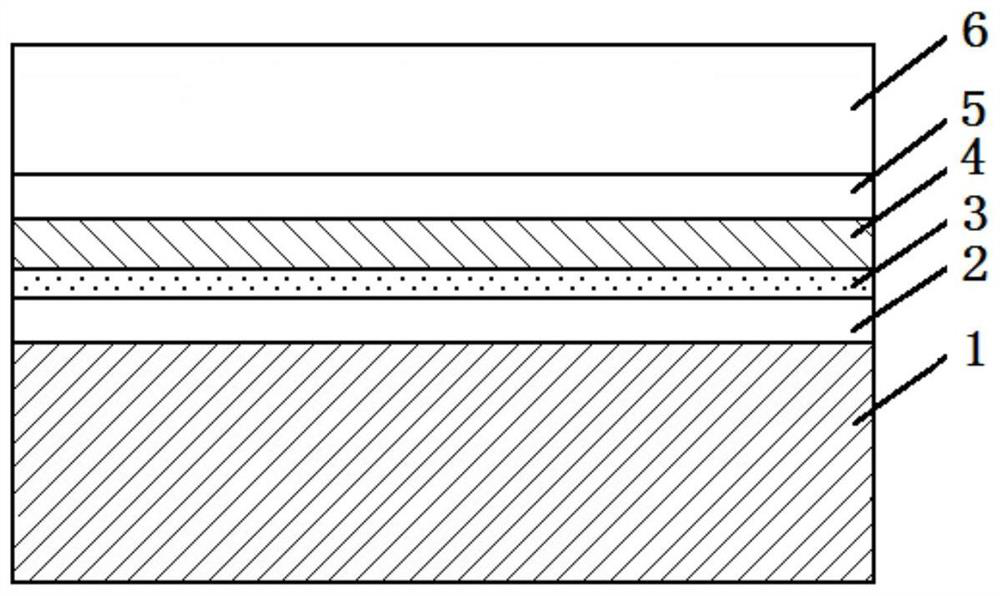

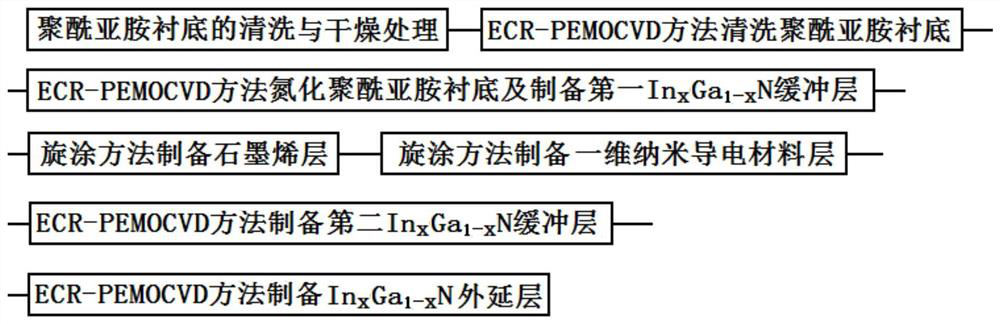

[0030] Embodiment one, such as figure 1 , as shown in 2, 3.

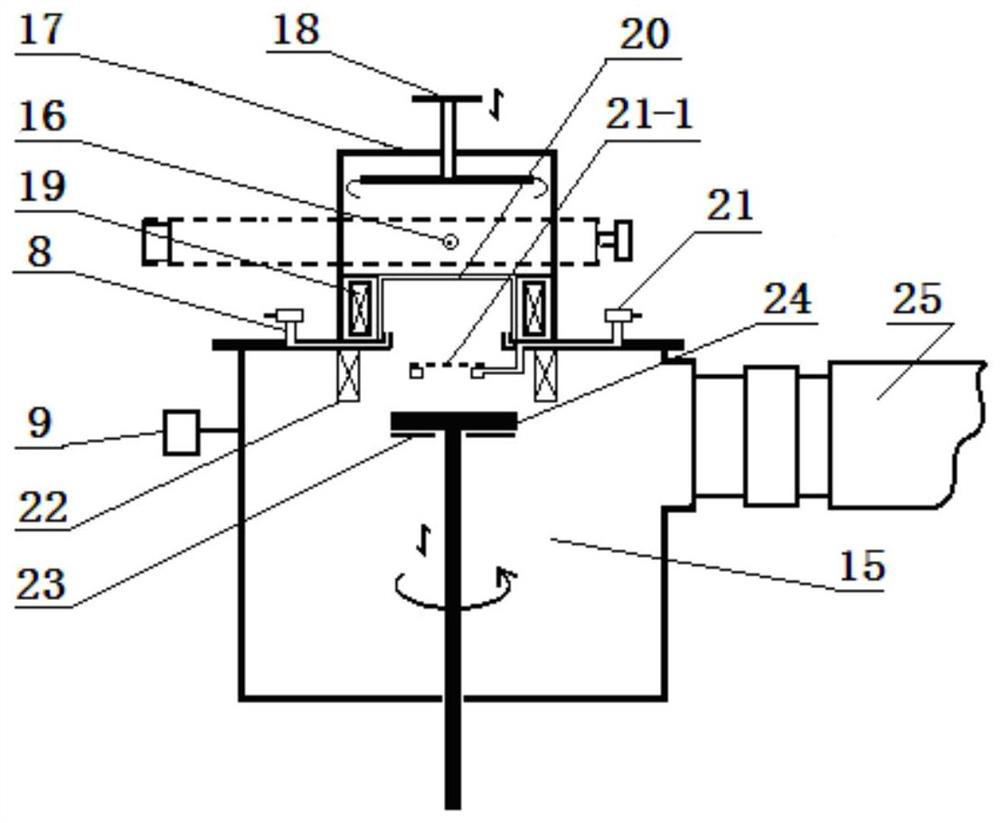

[0031] A kind of using ECR-PEMOCVD equipment (invention patent: ZL201210247144.8), gluing machine and gluing machine, prepared on polyimide substrate 1 as attached figure 1 Shown In 0.55 Ga 0.45 The continuous process steps of N thin film are:

[0032] a. ECR-PEMOCVD method to clean polyimide substrate 1: select a polyimide substrate 1 with a size of 3cm×3cm and a thickness of 200μm, first use a cotton ball soaked in absolute ethanol to wipe the polyimide substrate in one direction The surface of the imide substrate 1 was washed 3 times respectively, and then the polyimide substrate 1 was placed in absolute ethanol and deionized water and ultrasonically cleaned for 3 times, each time for 5 minutes, and then the polyimide substrate 1 was cleaned. Put it on a gluing machine at 120°C for drying treatment for 2 hours, then transfer the polyimide substrate 1 from the glove box of the ECR-PEMOCVD equipment to the samp...

Embodiment 2

[0041] Embodiment two, such as figure 1 , as shown in 2, 3.

[0042] In the second embodiment, except step d, other steps are completely the same as the first embodiment.

[0043] Step d in Example 2. Preparation of carbon nanotube layer 4 by spin coating method: Weigh 10 mg of multi-walled carbon nanotubes and put them into 100 ml of absolute ethanol for 24 hours of ultrasonic vibration to obtain carbon nanotubes with a concentration of 0.1 mg / ml. Nanotube dispersion, the diameter of the carbon nanotubes in the dispersion is 5 to 20nm, and the aspect ratio is 300 to 1200, and the hard substrate adhered to the polyimide substrate 1 is adsorbed on the homogenizer, and then Add the carbon nanotube dispersion liquid onto the graphene layer 3 dropwise, control the speed of the homogenizer to 3500rpm, and prepare the carbon nanotube layer 4 by spin coating, and use a glue baking machine at a temperature of 120°C and a nitrogen atmosphere after spin coating Drying for 5 hours, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com