Heat conduction type aramid nano insulation paper and preparation method thereof

A technology of insulating paper and aramid fiber, applied in the direction of organic insulators, plastic/resin/wax insulators, papermaking, etc., can solve the problem of low boron nitride retention rate affecting thermal conductivity, affecting strength and thermal conductivity, and losing the flexibility of aramid paper To solve problems such as mechanical properties and insulation properties, high strength, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of heat-conducting aramid nano-insulation paper, comprising the following steps:

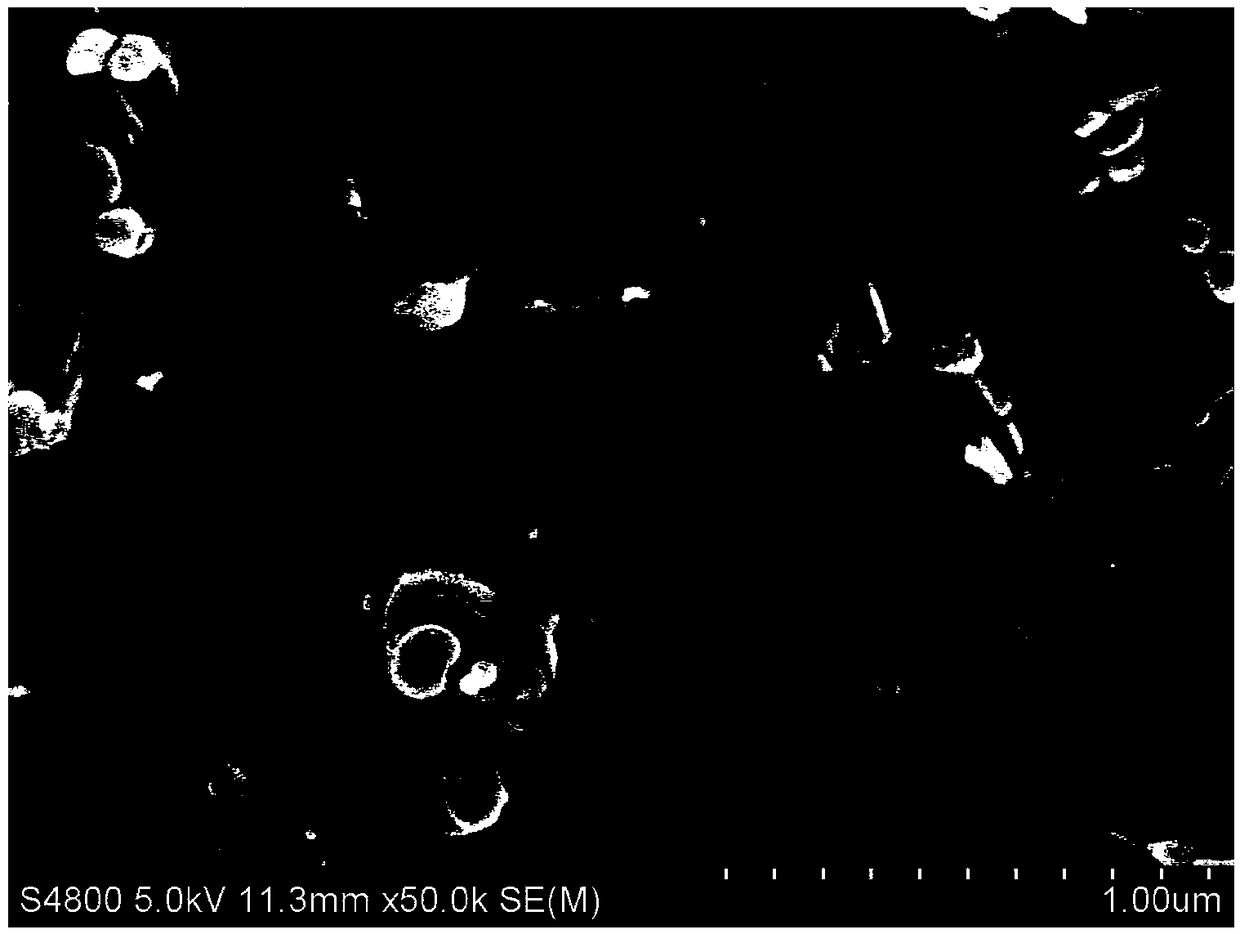

[0030] Step 1: Using one of para-aramid chopped fibers, para-aramid yarns, and para-aramid pulp fibers as a raw material, prepare aramid in a mixed solution system of potassium hydroxide and dimethyl sulfoxide Aramid nanofiber dispersion A; the aramid nanofiber dispersion A in the aramid nanofiber dispersion A has a diameter of 15-30 nm and a length of 3-10 μm; the aramid nanofiber dispersion A can be uniformly dispersed in water , the mass concentration of aramid nanofibers is 0.2-1.5%;

[0031] Step 2: adding nano-boron nitride with a particle size of 60-120 nm into a sodium hydroxide solution with a mass concentration of 20-60%, and performing modification treatment under the assistance of ultrasonic waves to obtain a hydroxylated nano-boron nitride dispersion B; The volume ratio of the nano boron nitride mass to the sodium hydroxide solution is 2-10mg / ml; the ult...

Embodiment 1

[0037] A heat-conducting aramid nano-insulating paper, the mass ratio of aramid nano-fibers to boron nitride in the heat-conducting aramid nano-insulating paper is 90:10; the aramid nano-fibers are para-aramid Yarn is used as a raw material, prepared in a mixed solution system of potassium hydroxide and dimethyl sulfoxide; the diameter of the aramid nanofiber is 15-30nm, and the length is 7-10μm; the aramid nanofiber is It has good dispersibility in the aqueous medium; the boron nitride crystal form is hexagonal whisker and has a flaky structure; the boron nitride is nano boron nitride with a particle size of 60-120nm; The nano-boron nitride is modified hydroxylated nano-boron nitride; the hydroxylated nano-boron nitride is made of boron nitride, and the sodium hydroxide solution with a mass concentration of 20% is assisted by ultrasonic waves. Prepared; the volume ratio of the nano boron nitride mass to the sodium hydroxide solution is 2mg / ml; the ultrasonic treatment process...

Embodiment 2

[0044] A heat-conducting aramid nano-insulating paper, the mass ratio of aramid nano-fibers to boron nitride in the heat-conducting aramid nano-insulating paper is 85:15; the aramid nano-fibers are para-aramid Chopped fibers are used as raw materials and prepared in a mixed solution system of potassium hydroxide and dimethyl sulfoxide; the diameter of the aramid nanofiber is 15-30 nm, and the length is 5-7 μm; the aramid nanofiber It has good dispersibility in the aqueous medium; the boron nitride crystal form is hexagonal whisker and has a thin sheet structure; the boron nitride is nano boron nitride, and its particle size is 60-120nm; The nano-boron nitride is modified hydroxylated nano-boron nitride; the hydroxylated nano-boron nitride is made of boron nitride, and the sodium hydroxide solution with a mass concentration of 30% is assisted by ultrasonic waves. The volume ratio of the nano boron nitride mass to the sodium hydroxide solution is 3mg / ml; the ultrasonic treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com