Polyetherimide containing anthrone and trifluoromethyl structure and preparation method thereof

A technology of polyetherimide and trifluoromethyl, which is applied in the field of polymer synthesis, can solve problems that have not caused researchers, and achieve the effects of low cost, improved light transmittance, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Synthesis of 9,9-bis(4-hydroxyphenyl)anthracene-10(9H)-one (BHPAO)

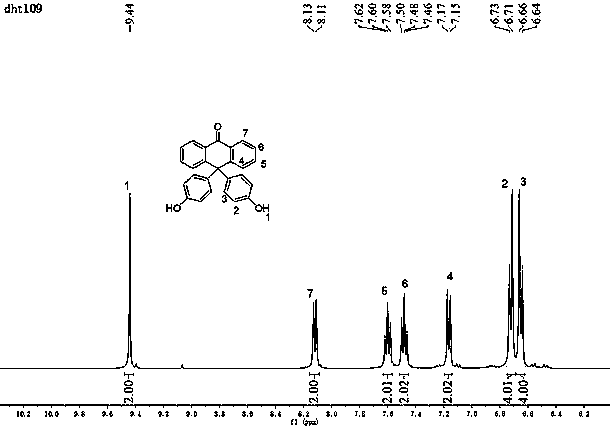

[0048]Add 19.4 g (0.1 mol) of xanthone and thionyl chloride (60 mL) into a 250 mL single-necked bottle, reflux for 2 hours, evaporate and recover the remaining thionyl chloride, continue to add 80 mL of xylene and 37 g of excess phenol ( 0.39mol), slowly heated to 130°C, reacted for 3h, stopped the reaction, cooled to room temperature, filtered, the residual solid was washed with an appropriate amount of dichloromethane to obtain a crude product, the crude product was recrystallized with acetone, and after drying, 34g of a light gray powder solid was obtained. The yield is 90%, and the melting point is 306-307°C. 1 H NMR (400MHz, DMSO-d 6 ): δ=9.44(s, 2H), 8.11(d, J=9.6Hz, 2H), 7.59(t, J=7.0Hz, 2H), 7.47(t, J=7.4Hz, 2H), 7.16(d ,J=7.9Hz,2H),6.72(d,J=8.7Hz,4H),6.65(d,J=8.7Hz,4H)( figure 1 ).

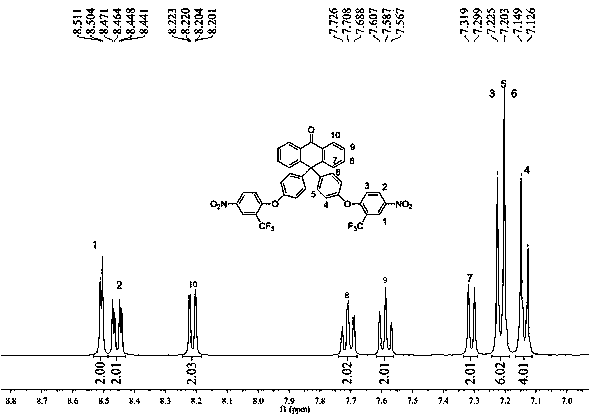

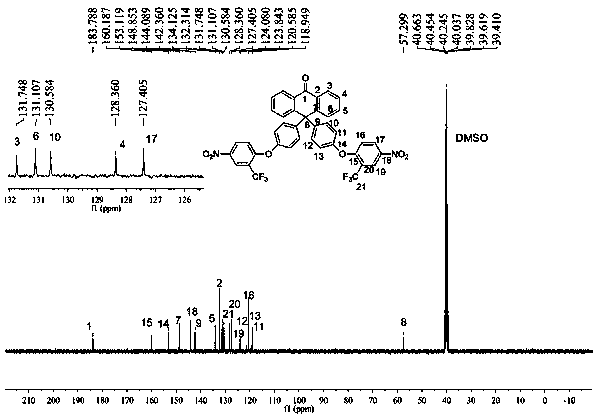

[0049] (2) Synthesis of 9,9-bis[4-(4-nitro-2-trifluoromethylphenoxy)phenyl]anthracene-10(9H)-one (BNTPP...

Embodiment 2

[0054] Preparation of polyetheramic acid PAA (taking PAA(a) as an example)

[0055] In pass have N 2 BATPPAO (1mmol, 0.696g) and DMAc (2mL) were first added to a 50mL three-necked flask, stirred in an ice-water bath until completely dissolved, then added perphthalic anhydride (PMDA) (1mmol, 0.218g), and then added DMAc, The solid content of the reaction system is controlled to be about 20%, and the reaction is performed in an ice-salt bath for 1 h, and then at room temperature for 10 h to obtain a transparent viscous polyether amic acid solution. Filter the polyether amic acid viscous liquid with 400-mesh nylon cloth to remove insoluble impurities, and spread the filtrate evenly on the treated and clean glass plate on a film laying machine with a constant temperature of 60°C, and evaporate most of it after 10 hours solvent, and then vacuum-baked at 100° C. for 12 hours to obtain a light yellow transparent polyamic acid PAA (a) film with uniform thickness.

Embodiment 3

[0057] Preparation of polyetherimide film (taking polyetherimide PI(b) as an example)

[0058] Under the protection of nitrogen flow, the polyether amic acid PAA (b) film was thermally cyclized at high temperature (using temperature programming) to become a polyimide PI (b) film. The thermal cyclization process is as follows: first, the temperature is raised from 50°C to 130°C at a rate of 10°C / min, and kept for 2 hours, then the temperature is raised to 210°C, and the rate of increase is 1°C / min, kept for 2 hours, and finally Adjust the temperature to 320°C, increase at a rate of 1°C / min, and keep for 2h.

[0059] (1) Infrared spectrum analysis of polyetherimide

[0060] Image 6 It is the infrared spectrum comparison chart of polyetheramic acid PAA (b) and polyetherimide PI (b) after thermal cyclization, as can be seen from the spectrogram, the characteristic peak of the amine group in the polyetherimide disappears, It shows that the imidization of amino group is complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com