Selenide @ carbon-based fiber supercapacitor electrode material and preparation method thereof

A supercapacitor, carbon-based fiber technology, applied in hybrid capacitor electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of low specific capacitance and low energy density, and achieve improved specific capacitance and excellent performance. Mechanical properties, the effect of facilitating the transfer of charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

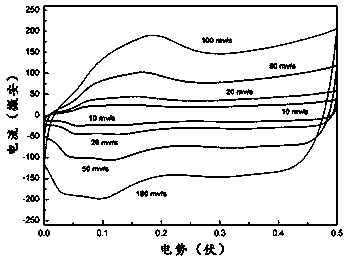

[0034] The carbon-based fiber is prepared by the spinning method as the core; the corresponding selenide is grown on the carbon-based fiber by the hydrothermal method or the magnetron sputtering method as the shell, and the selenide@carbon-based fiber composite material is prepared. In this example, the inventor selected a variety of selenides to test separately, and made various selenides@carbon-based fiber composite materials. The selenides grown on carbon-based fibers include cobalt selenide, nickel selenide, selenium Any of manganese selenide, iron selenide, vanadium selenide, tin selenide, niobium selenide, titanium selenide, copper selenide. Three-electrode test, the specific capacitance of each selenide@carbon-based fiber composite is shown in Table 1. For comparison, the specific capacitance of a single carbon-based fiber is also listed in the table.

[0035]

Embodiment 2

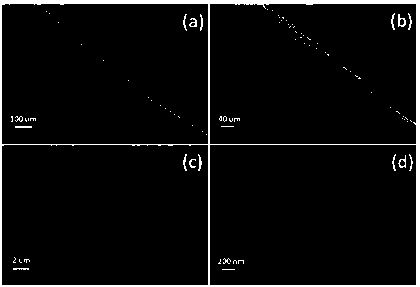

[0037](1) Mix 1 mmol cobalt chloride hexahydrate, 1 mmol sodium selenite and 40 mL deionized water, stir for 5-15 min to form a uniform pink solution, then slowly add 5 mL hydrazine hydrate (85 % N 2 h 4 ·H 2 O) as a reducing agent, continue stirring for 5-15 minutes to obtain a precursor solution;

[0038] (2) Hang the carbon nanotube fibers in the reaction kettle, add the precursor solution, carry out the hydrothermal reaction, the reaction temperature is 120-180 ℃, the time is 12-15 h, cool to room temperature, collect the fibers, wash and dry ;

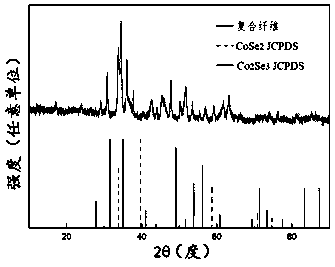

[0039] (3) In order to improve the crystallinity of cobalt selenide on the surface of the fiber, it was put into a tube furnace in an Ar atmosphere and annealed at 300-600 °C for 2 hours to obtain the cobalt selenide@carbon nanotube fiber supercapacitor electrode material .

[0040] The chemical raw materials cobalt chloride hexahydrate and sodium selenite used in the above examples are analytically pure, and the resistance o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com