Aluminum-doped three-dimensional nano-porous metal sulfide hydrogen evolution electrode preparation and application methods

A three-dimensional nano-porous metal technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve the problems of weak bonding force between the active layer and the conductive substrate, limited types of commercial foam metals, single pore size, shape and composition, etc. , to achieve the effects of improved microstructure and chemical stability, strong designability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

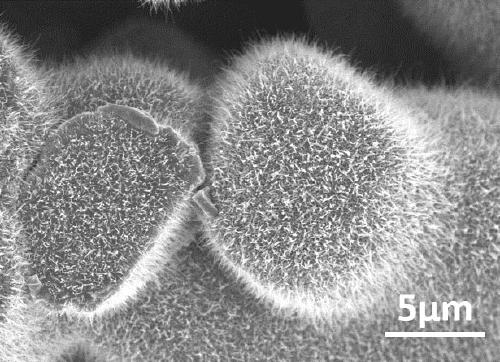

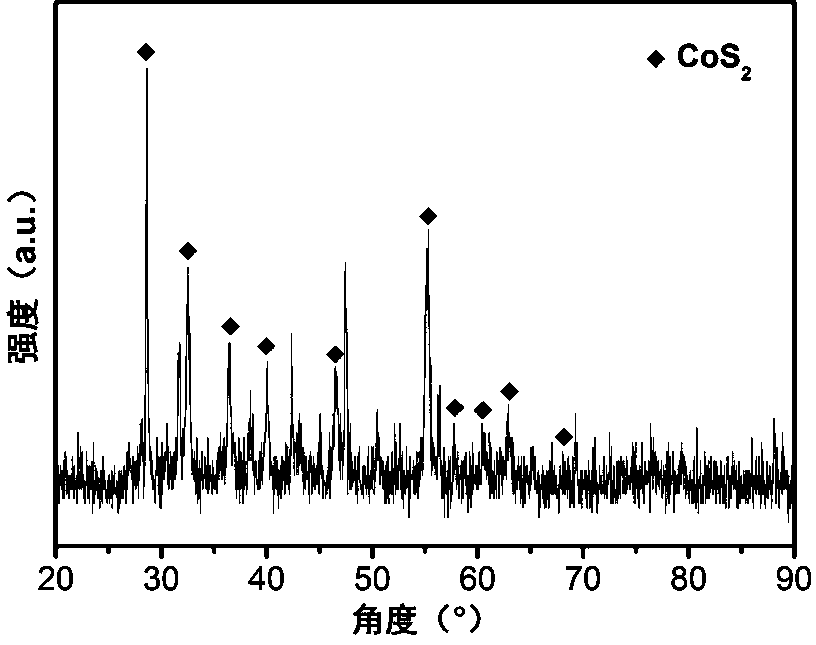

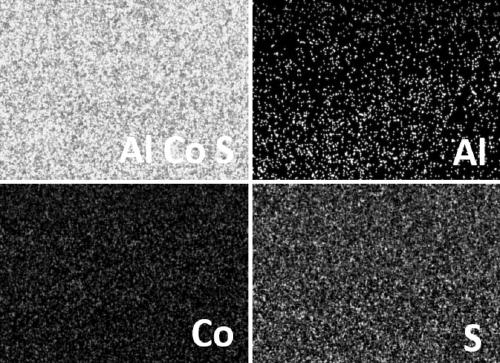

[0024] A method for preparing an aluminum-doped three-dimensional nanoporous cobalt sulfide hydrogen evolution electrode is carried out according to the following steps:

[0025] Step 1. Use a high-frequency induction melting furnace to heat cobalt and aluminum together to a molten state (the atomic percentage of aluminum is 90%), blow the molten alloy liquid into a graphite crucible with argon gas, and cool it under the protection of argon gas To form a rod-shaped alloy ingot, cut the alloy ingot into discs with a diameter of 14mm and a thickness of 1mm, and grind and polish the surface of the alloy sheet;

[0026] Step 2, the aluminum-cobalt alloy sheet obtained in step 1 is dealloyed in a sodium hydroxide solution with a molar concentration of 6mol / L, the reaction time is 0.5h, and then rinsed with ultrapure water several times and dried to obtain Nanoporous cobalt sheet;

[0027] Step 3, place the nanoporous cobalt sheet in the tubular annealing furnace, place the sulfur ...

Embodiment 2

[0030] A method for preparing an aluminum-doped three-dimensional nanoporous nickel sulfide hydrogen evolution electrode is carried out according to the following steps:

[0031] Step 1. Use a high-frequency induction melting furnace to heat nickel and aluminum together to a molten state (the atomic percentage of aluminum is 85%), blow the molten alloy liquid into a graphite crucible with argon gas, and cool it under the protection of argon gas To form a rod-shaped alloy ingot, cut the alloy ingot into discs with a diameter of 10mm and a thickness of 2mm, and grind and polish the surface of the alloy sheet;

[0032] Step 2, the aluminum-nickel alloy sheet obtained in step 1 is dealloyed in a potassium hydroxide solution with a molar concentration of 2mol / L, and the reaction time is 1.5h, then rinsed with ultrapure water several times and then dried to obtain Nanoporous nickel sheet;

[0033] Step 3, place the nanoporous nickel sheet in the tubular annealing furnace, place the...

Embodiment 3

[0035] A method for preparing an aluminum-doped three-dimensional nanoporous iron sulfide hydrogen evolution electrode is carried out according to the following steps:

[0036]Step 1. Use a high-frequency induction melting furnace to heat iron and aluminum together to a molten state (the atomic percentage of aluminum is 90%), blow the molten alloy liquid into a graphite crucible with argon gas, and cool it under the protection of argon gas To form a rod-shaped alloy ingot, cut the alloy ingot into discs with a diameter of 20mm and a thickness of 1.5mm, and grind and polish the surface of the alloy sheet;

[0037] Step 2. The aluminum-iron alloy sheet obtained in step 1 is dealloyed in a sodium hydroxide solution with a molar concentration of 1 mol / L. The reaction time is 1 h, and then rinsed with ultrapure water several times and dried to obtain nanoporous Iron sheets;

[0038] Step 3, place the nanoporous iron sheet in the tubular annealing furnace, place the sulfur powder u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com