A heat-resistant water-based sizing agent for carbon fiber and its preparation method and application

A carbon fiber and sizing agent technology, which is applied in the field of carbon fiber manufacturing, can solve the problems of large specific gravity, sizing agent cannot be used in high temperature resistant thermoplastic resin-based composite materials, environmental pollution, etc., to improve interface performance, improve agglomeration phenomenon, and improve wettability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

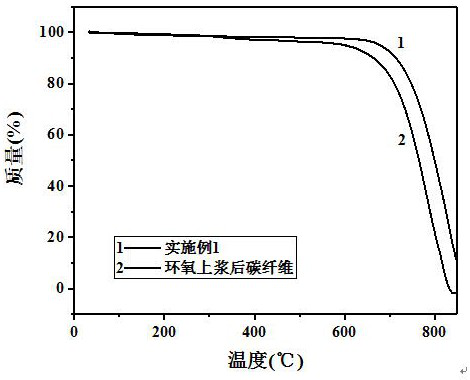

Examples

Embodiment 1

[0038] Step 1: Preparation of reduced graphene oxide-magnetic particles

[0039] (1) 0.2g graphene oxide is dispersed in 100ml deionized water and ultrasonically treated for 0.5h;

[0040] (2) 0.81g FeCl 3 ·6H 2 O and 0.42g FeSO 4 •7H 2 O was dispersed in 100ml of deionized water, and then added to the solution of (1);

[0041] (3) Add dropwise 0.5mol / l sodium hydroxide solution to the suspension, adjust the pH value of the suspension to 9, adjust the reaction temperature to 75°C in the presence of a magnetic field, and stir for 2h;

[0042] (4) Add 1ml of hydrazine hydrate, and stir the new mixture at 90°C for 4h to ensure complete reduction of graphene oxide;

[0043](5) The obtained solid product was washed three times with ethanol, and dried in an oven at 60°C for 12h.

[0044] Step 2: Preparation of Polyamic Acid (PAA) Aqueous Dispersion

[0045] (1) Add 160ml N,N-dimethylformamide to a 250ml three-necked flask, mix 0.05mol 3,3',4,4'-benzophenone tetracarboxylic di...

Embodiment 2

[0053] A heat-resistant water-based sizing agent for carbon fibers and a preparation method thereof are the same as in Example 1, except that the organic solvent used in step 2 (4) is dimethylethanolamine.

[0054] After testing, put the carbon fiber tow in the sizing device, soak the carbon fiber in the sizing agent for 30s, and then dry it in a drying oven at 200°C for 10 minutes to obtain a carbon fiber with a sizing amount of 0.5%. The interlaminar shear strength of the carbon fiber reinforced polyethersulfone resin-based composite material sized by the water-based sizing agent is 32.8MPa, compared with the interlaminar shear strength 26.8MPa of the carbon fiber reinforced polyethersulfone composite material after epoxy sizing agent sizing, increase up 22.4%.

Embodiment 3

[0056] A heat-resistant water-based sizing agent for carbon fibers and a preparation method thereof, the same as in Example 1, the difference is that 0.237g of reduced graphene oxide-magnetic particle solids are added to the PAA aqueous dispersion, and diluted with deionized water to 158ml. The mass fraction of polyamic acid in the sizing agent is 1.5%, and the concentration of reduced graphene oxide-magnetic particles is 1.5mg / ml.

[0057] After testing, the carbon fiber tow was placed in the sizing device, the carbon fiber was immersed in the sizing agent for 30s, and then dried in a drying oven at 200°C for 10 minutes, so that the sizing amount of the carbon fiber was 1%. The interlaminar shear strength of the carbon fiber reinforced polyethersulfone resin-based composite material sized by the water-based sizing agent is 35.2MPa, compared with the interlaminar shear strength 26.8MPa of the carbon fiber reinforced polyethersulfone composite material after epoxy sizing agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com