Anisotropic micro-trend structure material, preparation method thereof and application of material

An anisotropic and structural material technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of limited range of microstructure, limited range of gradient change, and practical application limitations, etc., to achieve The effect of good practical application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

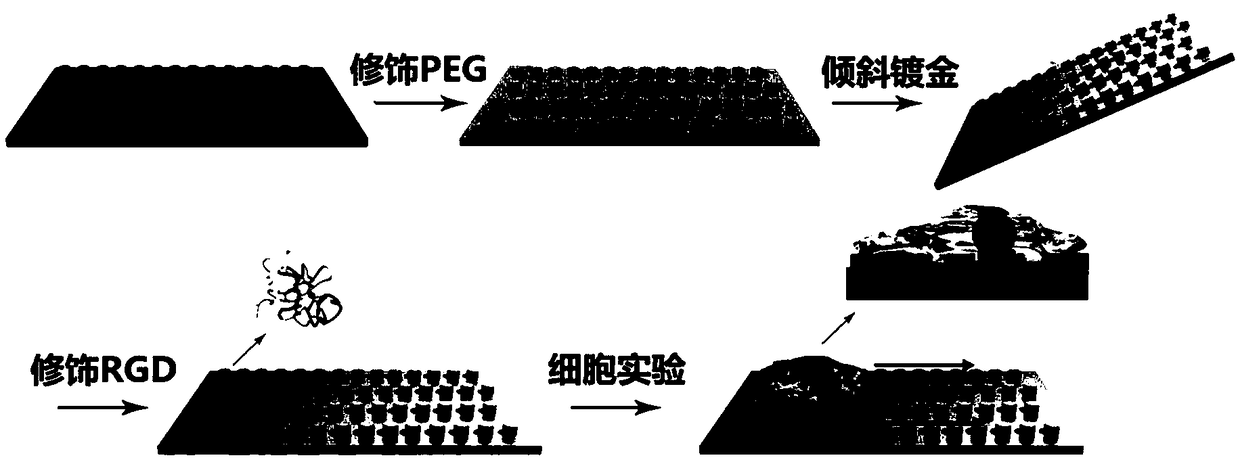

[0066] A kind of anisotropic microtendency structure material, its preparation method is as follows figure 1 shown, including:

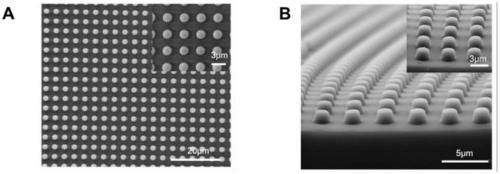

[0067] 1. The silicon substrate template containing the microporous structure (the size of the holes on the silicon substrate is 5 microns in depth, 5 microns in diameter, 5 microns in spacing between the holes, and a construction range of 2 cm × 2 cm), using absolute ethanol, Ultrasonic cleaning with acetone twice under low power conditions, each time for 5 minutes, after cleaning, use nitrogen to dry the surface;

[0068] 2. Put the dried surface into an airtight container, drop a few drops of dimethyldichlorosilane into the container to fluorinate the surface to reduce the surface activation energy, and the fluorination time is 30 minutes;

[0069] 3. During the fluorination process of the substrate, mix the PDMS prepolymer and the curing agent according to the mass ratio of 10:1, stir the mixed solution into a vacuum desiccator, pump for 1 hour,...

experiment example 1

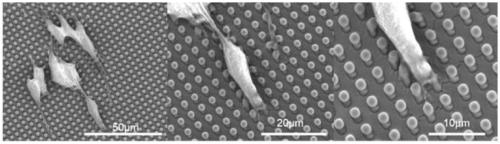

[0080] Utilize the anisotropic microtaxis structure material that embodiment 1 makes to study the migration of cell on its surface:

[0081] 1. Transfer the modified anisotropic material to ultraviolet light for 2 hours of irradiation and sterilization, and use it as a substrate for cell migration experiments:

[0082] 2. Use trypsin to digest melanoma cells overgrown in a culture dish and prepare a cell suspension of 10,000 cells per milliliter;

[0083] 3. Put the modified PDMS sample into a small petri dish (diameter 35mm, height 10mm), add 3mL of the above cell suspension to the petri dish and transfer to the living cell workstation;

[0084] 4. Connect the living cell workstation to an inverted fluorescence microscope, set it at 37°C, and inject 5% CO2 gas for 24 hours of living cell culture;

[0085] 5. During the culture process, use the camera system attached to the microscope to take pictures of the observation area, and evaluate the migration of cells on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com