Sound absorbing material and speaker using sound absorbing material

A sound-absorbing material and molecular sieve technology, applied in the field of loudspeakers, can solve the problems of poor crystallinity of MEL structure, no low-frequency improvement effect, attenuation of acoustic performance, etc., to increase long-term stability, increase resistance to VOCs and resistance to performance attenuation, The effect of not easy to absorb water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides the preparation method of the above-mentioned sound-absorbing material:

[0050] Step 1: Using a silicon source, an alkali source, a template agent, a M source and hydration to synthesize a molecular sieve with a MEL structure in which the mass of the silicon element and the element M is between 150 and 2000.

[0051] Regarding step one, specifically, the M source is an element M source (neither a silicon element source), and the synthesis raw materials (silicon source, M source, template agent, alkali source, etc.) are added to the synthesis reaction kettle, and then passed The crystallization reaction obtains molecular sieve powder with MEL structure. The crystallization reaction is generally carried out in the water phase for a certain period of time, also known as hydrothermal reaction; the temperature of the hydrothermal reaction is generally from room temperature to 250°C, preferably from room temperature to 180°C; the pressure ...

Embodiment 1

[0061] The sound-absorbing material of this embodiment includes MEL and MFI mixed-phase structural molecular sieves, and its preparation method is as follows:

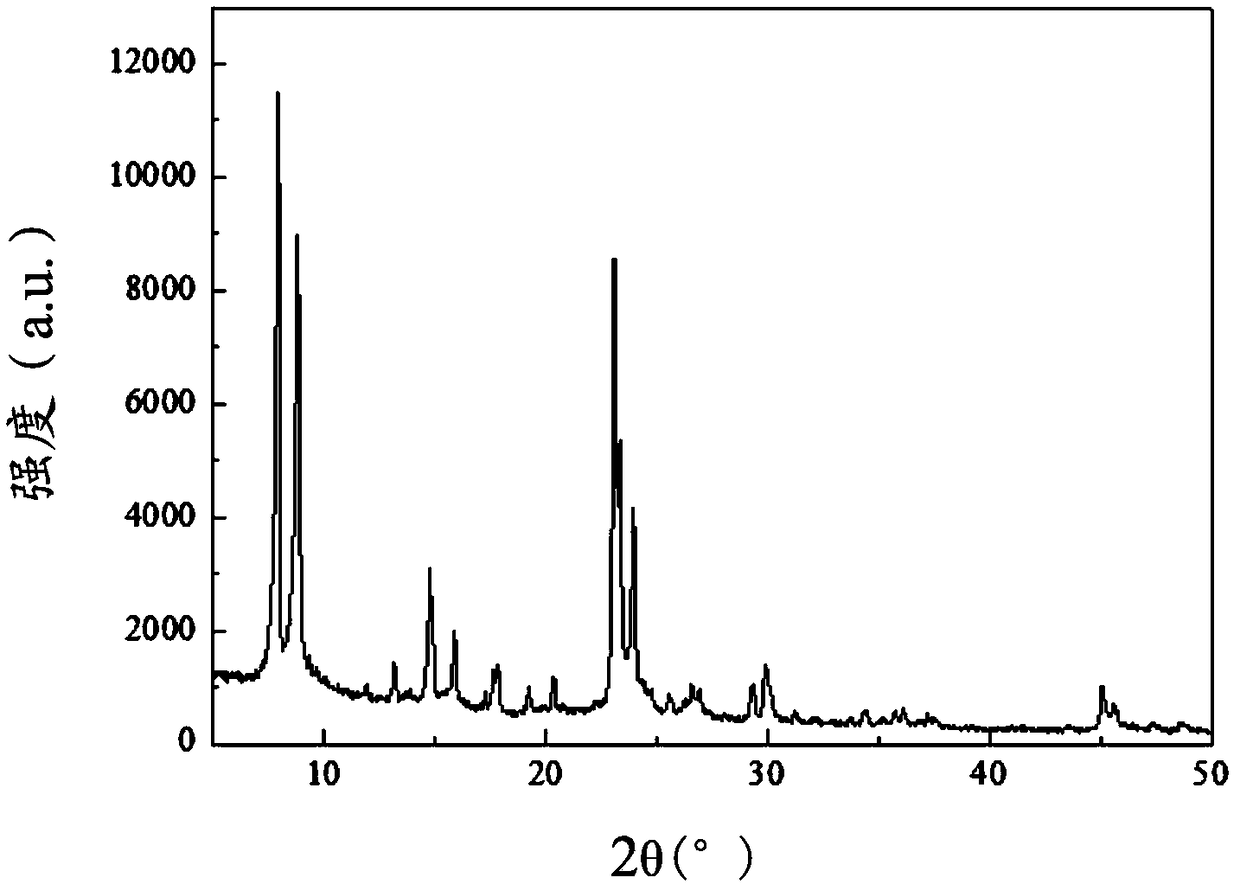

[0062] Use silicon source (including orthosilicate, silica sol, sodium silicate, etc.), aluminum source (aluminum nitrate, sodium metaaluminate, aluminum isopropoxide, etc.), alkali source (sodium hydroxide, potassium hydroxide and hydrogen Lithium oxide), template agent is tetrabutyl quaternary ammonium salt (at least one of tetrabutyl ammonium bromide, tetrabutyl ammonium hydroxide, tetrabutyl ammonium chloride, tetrabutyl ammonium iodide and tetrabutyl ammonium fluoride species) and hydrated Si / Al mass ratio of 250 MEL and MFI miscible structure molecular sieve, its XRD pattern is shown in figure 1 Shown, low-temperature nitrogen adsorption characterization see Figure 4 Shown, normal temperature nitrogen adsorption and desorption see Figure 6 shown.

Embodiment 2

[0064] The sound-absorbing material of this embodiment includes MEL and MFI mixed-phase structural molecular sieves, and its preparation method is as follows:

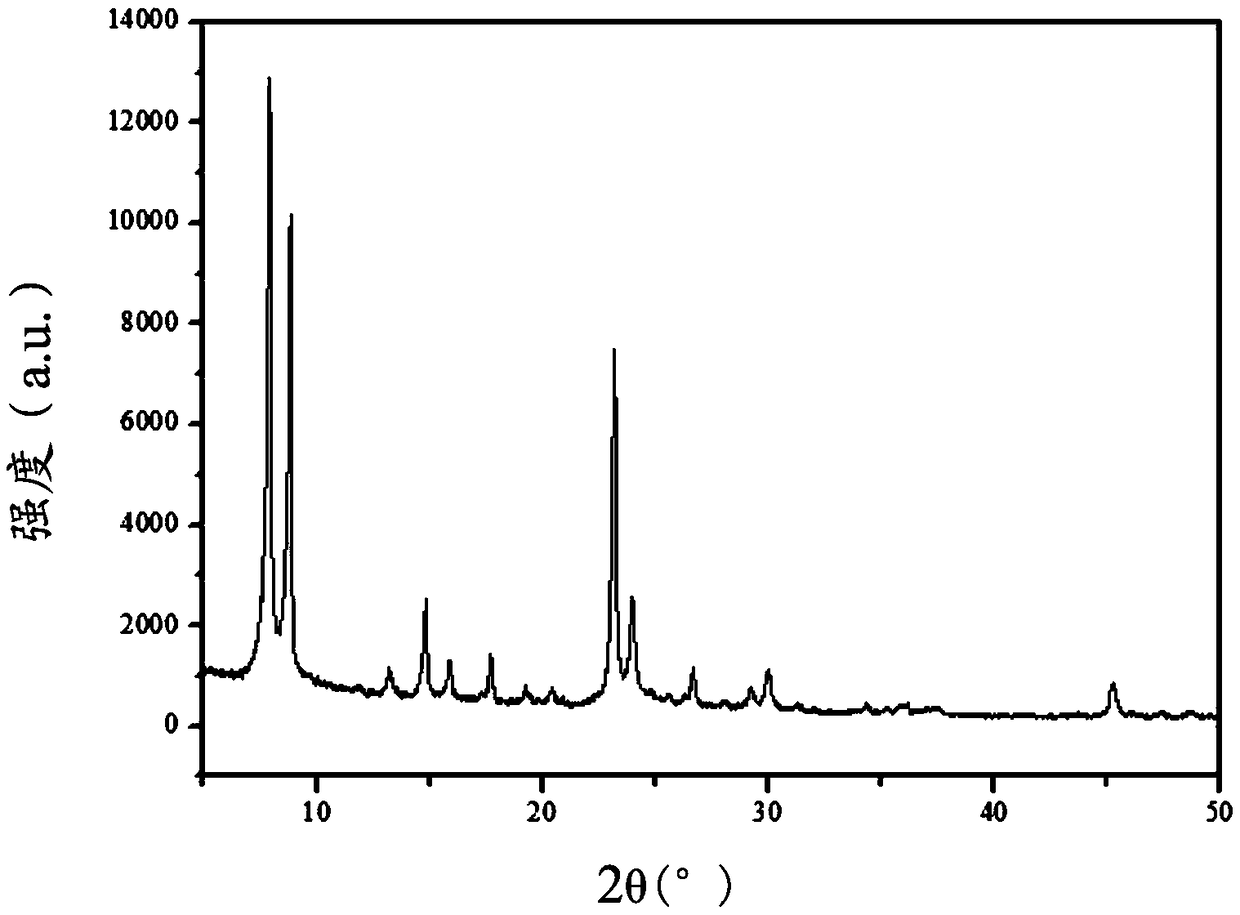

[0065] Use silicon source (including orthosilicate, silica sol, sodium silicate, etc.), iron source (ferric nitrate, ferric sulfate and ferric chloride), alkali source (sodium hydroxide, potassium hydroxide and lithium hydroxide), Template agent is tetrabutylammonium salt (at least one in tetrabutylammonium bromide, tetrabutylammonium hydroxide, tetrabutylammonium chloride, tetrabutylammonium iodide and tetrabutylammonium fluoride) and water Synthesized MEL and MFI mixed-phase structure molecular sieves with a Si / Fe mass ratio of 300, the acoustic properties are shown in Table 1, and the low-temperature nitrogen adsorption characterization is shown in Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com