Calcium phosphate/bioactive glass bone repair bracket and preparation method thereof

A technology of bioactive glass and calcium phosphate bone, which is applied in the field of bone repair materials, can solve problems such as the inability to manufacture bone repair scaffolds, the inability to control the pore size, and the toxic and side effects of pore-forming agents, so as to avoid excessive coagulation time and excellent biophase Capacitance, effect of shortening setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

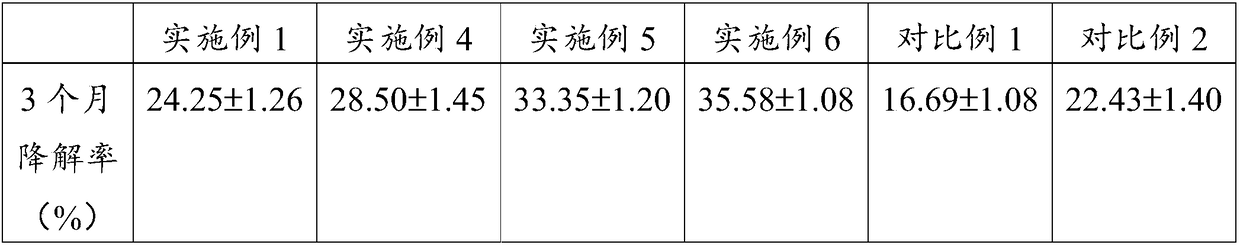

Examples

Embodiment 1

[0043] A preparation method of calcium phosphate / bioactive glass bone repair bracket, comprising the following steps:

[0044] (1) The bone cement solid phase powder and bioactive glass are mixed in a mass ratio of 1:0.04 to obtain a mixed powder; the solid phase powder includes polyethylene glycol, tetracalcium phosphate and calcium dihydrogen phosphate, and the solid phase powder The massfraction of polyethylene glycol in the medium is 0.01%;

[0045] (2) Mix the mixed solid phase powder and the solidified liquid according to the solid-to-liquid ratio of 1g:0.45mL to obtain calcium phosphate bone cement slurry;

[0046] Dissolving xanthan gum and white dextrin in 0.25 mol / L disodium hydrogen phosphate solution to form a solidified solution, wherein the mass fraction of xanthan gum in the solidified solution is 0.5%, and the mass fraction of white dextrin is 0.5%;

[0047] (3) The calcium phosphate bone cement slurry is printed by 3D printing technology to obtain the calcium p...

Embodiment 2

[0054] A preparation method of calcium phosphate / bioactive glass bone repair bracket, comprising the following steps:

[0055] (1) The bone cement solid phase powder and bioactive glass are mixed at a mass ratio of 1:0.04 to obtain a mixed powder; the solid phase powder includes polyethylene glycol, α-tricalcium phosphate, calcium carbonate and calcium hydrogen phosphate, so The massfraction of polyethylene glycol in the solid phase powder is 0.6%;

[0056] (2) Mix the mixed solid phase powder and the solidified liquid according to the solid-to-liquid ratio of 1g:0.5mL to obtain calcium phosphate bone cement slurry;

[0057] Dissolving xanthan gum and white dextrin in 0.25 mol / L disodium hydrogen phosphate solution to form a solidified solution, wherein the mass fraction of xanthan gum in the solidified solution is 0.5%, and the mass fraction of white dextrin is 0.5%;

[0058] (3) The calcium phosphate bone cement slurry is printed by 3D printing technology to obtain the calc...

Embodiment 3

[0065] A preparation method of calcium phosphate / bioactive glass bone repair bracket, comprising the following steps:

[0066] (1) Mix the bone cement solid phase powder and bioactive glass at a mass ratio of 1:0.06 to obtain a mixed powder; the solid phase powder includes polyethylene glycol, α-tricalcium phosphate, strontium-doped octacalcium phosphate and strontium-doped Amorphous calcium phosphate; in the solid phase powder, the molar ratio of strontium to calcium is: strontium:calcium=0.1:1; the molar ratio of the sum of calcium and strontium to phosphorus is: calcium+strontium:phosphorus=1.1: 1; the mass fraction of polyethylene glycol in the solid phase powder is 0.6%;

[0067] (2) Mix the mixed solid phase powder and the solidified liquid according to the solid-to-liquid ratio of 1g:0.45mL to obtain calcium phosphate bone cement slurry;

[0068] Dissolving xanthan gum and white dextrin in 0.25 mol / L disodium hydrogen phosphate solution to form a solidified solution, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com