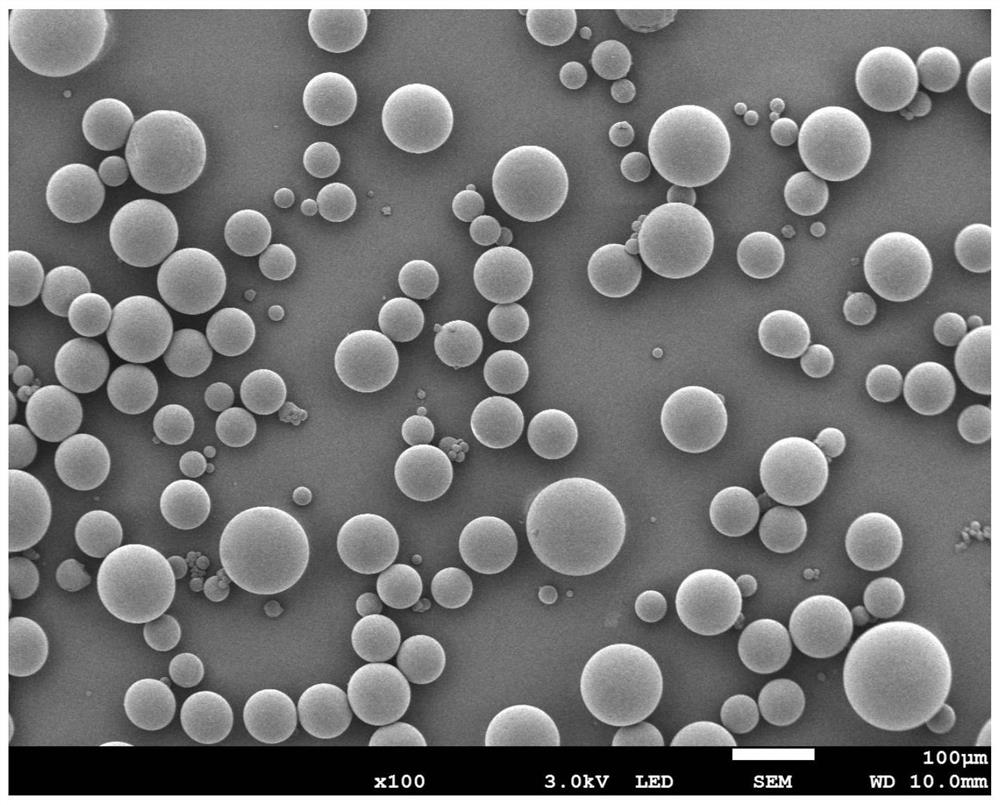

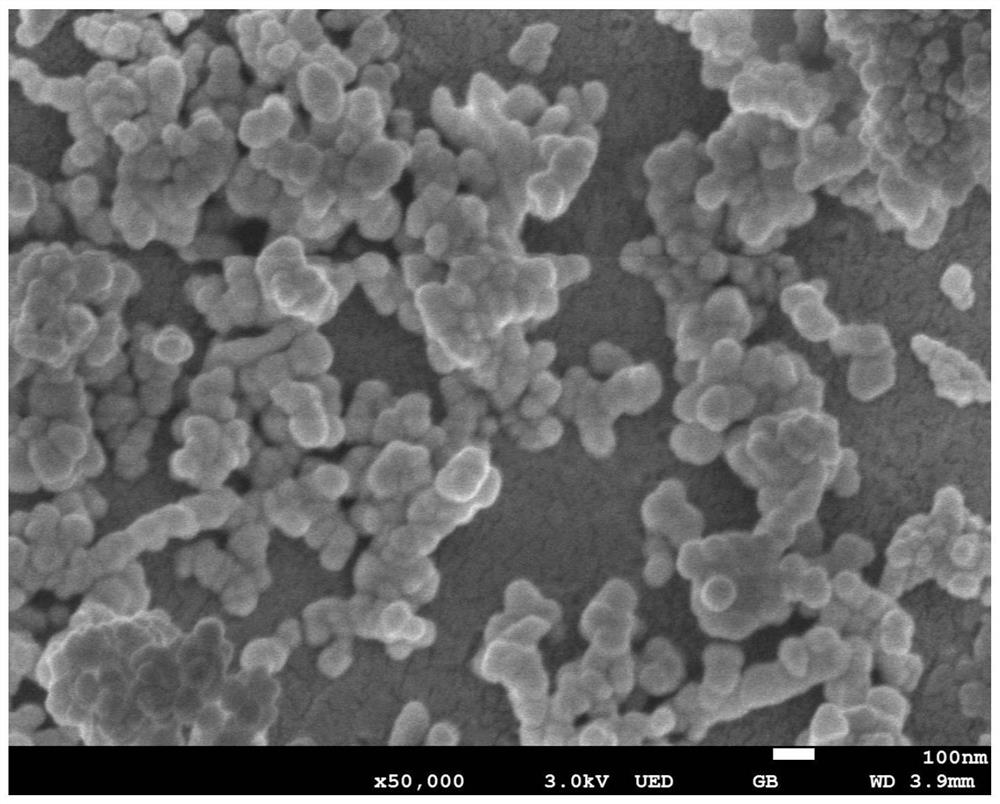

Low-temperature heat-expandable microspheres, preparation method and application thereof

A heat-expandable microsphere, unsaturated technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problem of insufficient inhibition of heat-expandable microcapsule agglomeration, achieve high expansion performance, improve dispersibility, and solve the effect of cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

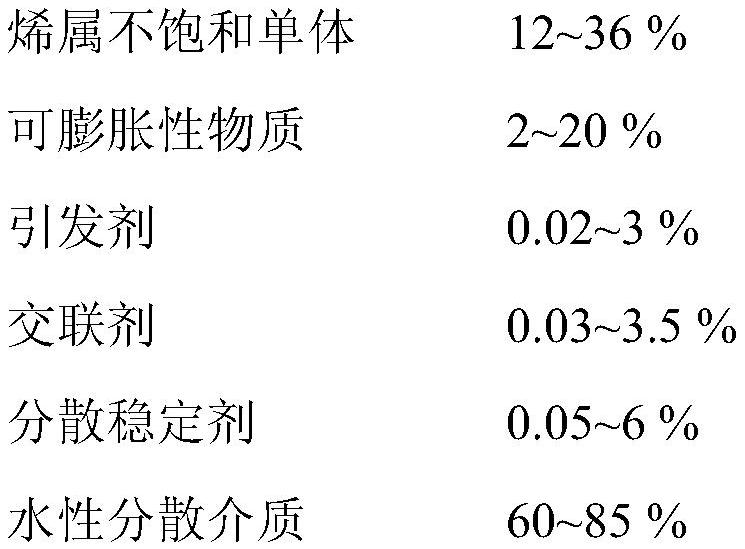

[0051] By mixing 70g acrylonitrile, 40g methyl acrylate, 20g methyl methacrylate, 5.0g polyethylene glycol methyl ether methacrylate, 3.5g azobisisobutyronitrile, 0.7g tris(ethylene glycol) bis( Meth)acrylate and 40 g of isopentane give a suspension polymerized oil phase.

[0052] Add 250g of deionized water, 20g of sodium hydroxide, 10g of calcium chloride and 0.15g of sodium lauryl sulfate into the No. 1 beaker to fully dissolve; add 250g of deionized water, 5g of calcium chloride, and 5g of sulfuric acid into the No. 2 flask Magnesium, 0.01g of sodium nitrite is fully dissolved; first pour the solution in the No. 1 beaker into a 2L three-necked flask with a stirring paddle, then stir at a speed of 1000rpm, and then slowly add it into the No. 2 flask The solution. After the addition was complete, the mixture was fully stirred for 10 minutes to obtain a suspension-polymerized aqueous phase.

[0053] A suspension solution was prepared by dispersing the oil phase and the wate...

Embodiment 2-10

[0055] See Table 1, except that the type and amount of monomers, initiators, crosslinking agents and blowing agents used were changed, the polymerization temperature was 73°C, and the polymerization time was 20 hours. Other conditions were the same as in Example 1, and the obtained The properties of heat-expandable microspheres are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com