A boron-doped negative electrode material with good high-temperature performance and a solid-phase preparation method thereof

A technology of negative electrode material and high temperature performance, which is applied in the field of boron-doped negative electrode material and its solid-phase preparation, can solve the problems such as the difficulty of large-scale application of non-metallic doping modification, and achieve the characteristics of easy promotion, reduction of defects and unique structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The solid phase preparation method of above-mentioned negative electrode material, comprises the following steps:

[0038] 1) Take the powder of the negative electrode substrate, add a boron compound to the powder, then add it to a high-speed mixer, and stir evenly to obtain a mixed powder;

[0039] 2) transfer the mixed powder of the mixed powder into a carbonization equipment, and heat it to 600-1200° C. under a protective atmosphere, preferably 800-1000° C., keep it warm, take it out after natural cooling, and obtain the negative electrode material;

[0040] 3) 3) Sieving the negative electrode material to obtain a finished negative electrode material.

[0041] As a preference, in step 1), the stirring time is 1-10 h, preferably 1-5 h.

[0042] As a preference, in step 2), the holding time is 1-24h, preferably 3-10h.

[0043] Preferably, in step 3), the median particle size of the obtained negative electrode material is 1-30 microns, preferably 3-10 microns.

[00...

Embodiment 1

[0046] Example 1: Boron-doped high-temperature negative electrode material doped with 2% boric acid dopant.

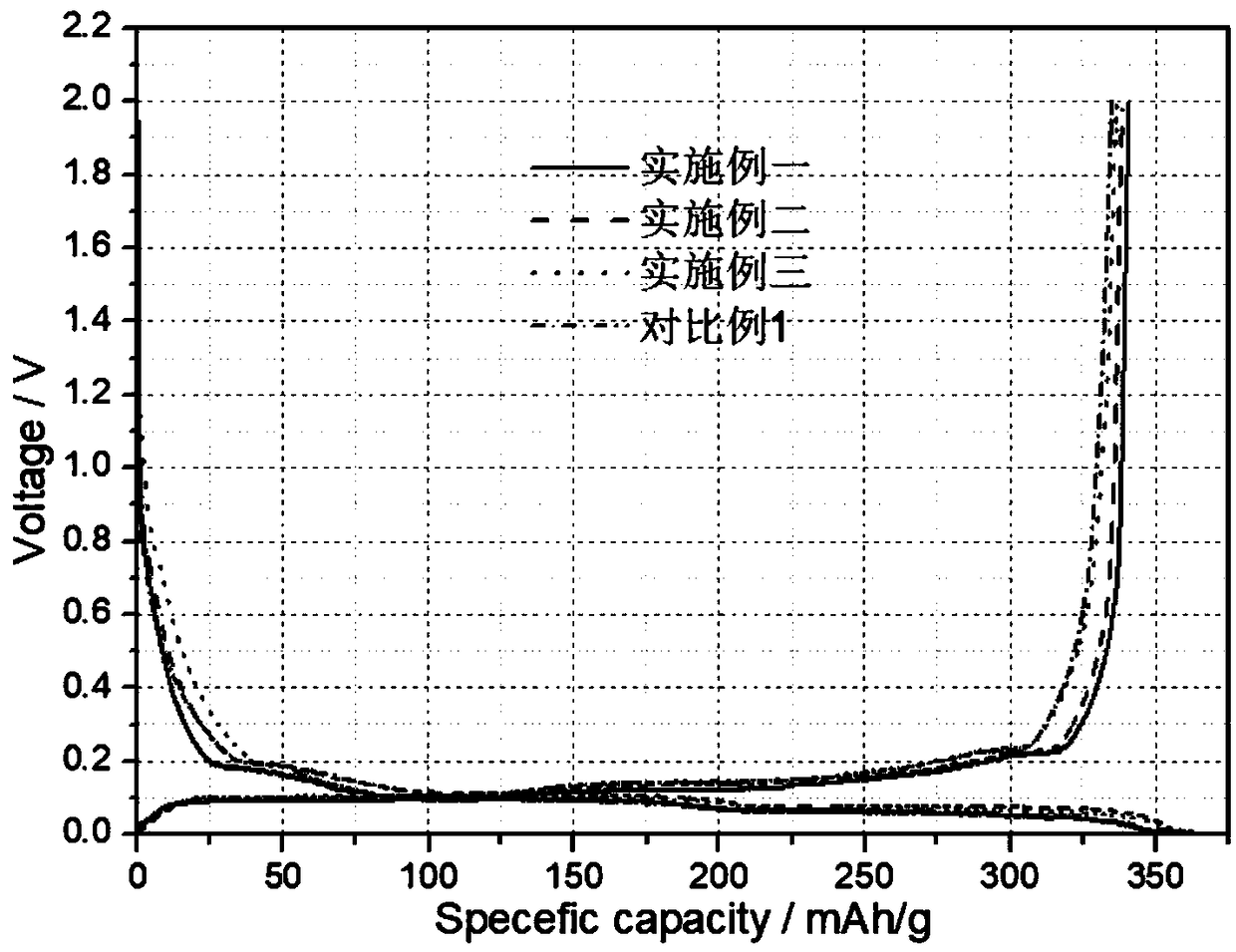

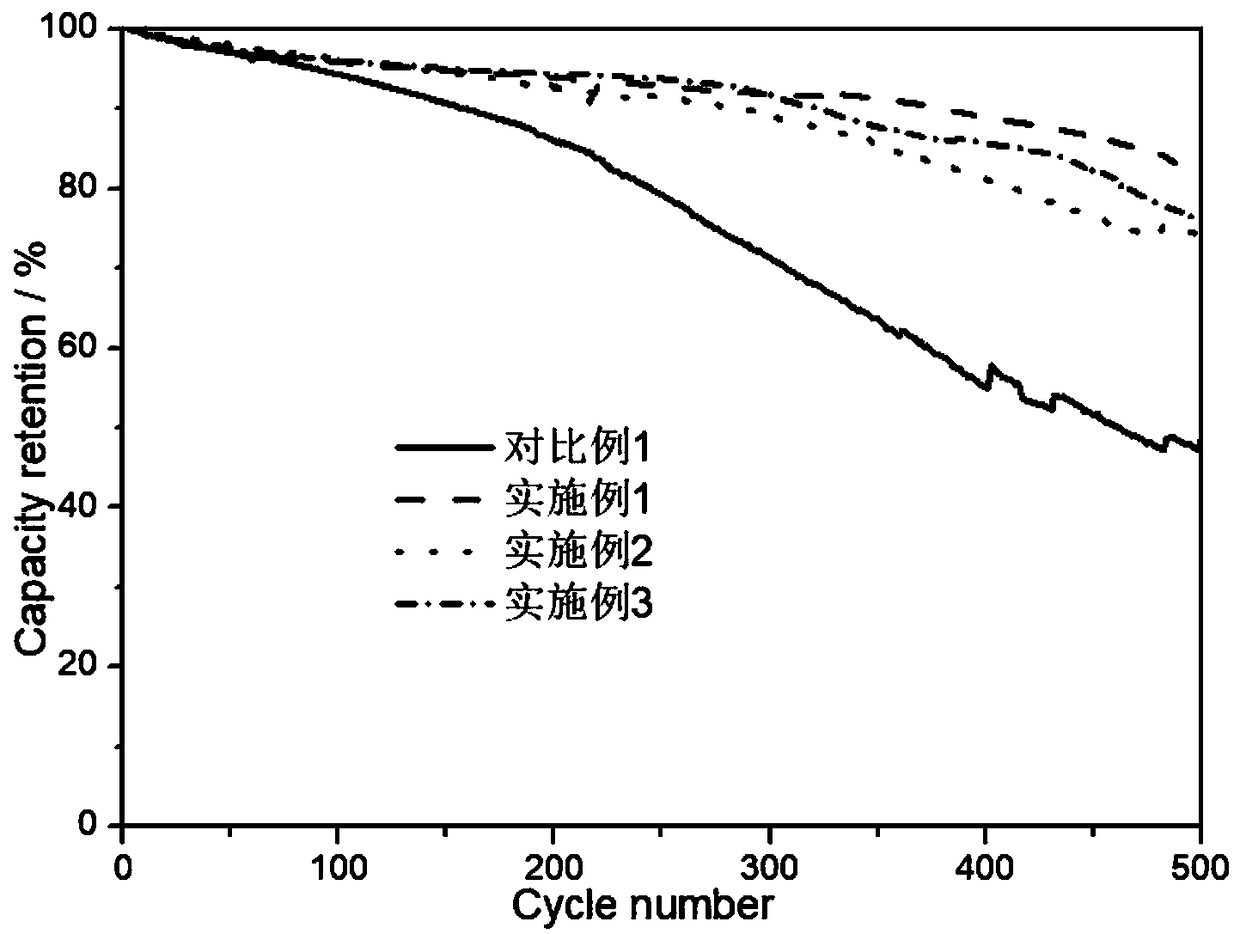

[0047] Take 4g of boric acid powder (median particle size is 3 microns) and add 200g of graphite negative electrode material (median particle size is 6.60 μm), then add it to a high-speed mixer, stir rapidly for 1 hour, after mixing evenly, transfer to alumina In the crucible, under a nitrogen atmosphere, heat up to 1000° C., heat for 10 hours, and then sieve through a 325-mesh sieve to obtain a boron-doped high-temperature negative electrode material with a doping ratio of 2% boric acid. The prepared product was uniformly mixed with SP, CMC, and SBR according to the ratio of 95.2:1:1.9:1.9, and after beating, coating, and rolling, a negative electrode sheet was formed on a copper grid, and then a lithium sheet was used as a counter electrode to make a button battery. Conduct charge and discharge tests, and use lithium cobalt oxide as the positive electrode to conduct ...

Embodiment 2

[0049] Example 2: Boron-doped high-temperature negative electrode material doped with 0.5% boric acid dopant.

[0050] Take 1g of boric acid powder (the median particle size is 5 microns) and add 200g of graphite negative electrode material (the median particle size is 6.60 μm), and then add it to a high-speed mixer, stir rapidly for 1 hour, and after mixing evenly, transfer to alumina In the crucible, under a nitrogen atmosphere, the temperature was raised to 1100° C., heated for 10 hours, and the negative electrode material was obtained after natural cooling. Pass the fluorine gas through the cooling medium containing calcium chloride and ice and the filter layer of sodium fluoride at 100 °C in sequence, then pass it into the reaction furnace, add the negative electrode material into the reaction furnace, and react at 425 °C for 5 hours to obtain the primary modified negative electrode material. Take 130g of the primary modified negative electrode material and add it to 1L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com