Method used for catalytic degradation of arylamine waste water using photocatalysis material

A photocatalytic and aromatic amine technology, applied in chemical instruments and methods, special compound water treatment, light water/sewage treatment, etc., can solve the problems of poor biodegradability, difficult high-concentration aniline wastewater, treatment, etc., and achieve the cost of wastewater treatment Reduced, widely used, cost-reduced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of composite photocatalyst of nickel-doped zinc tungstate:

[0036] 1) Carrier preparation: put 4.0g of diammonium hydrogen phosphate and 6.0g of calcium nitrate in water, stir and mix, add hydrochloric acid dropwise to adjust the solution until it is clear, stir for 3-5min, then add 2-3g of urea, react at 90°C for 2-3h , ultrasonically aged for 24 hours, filtered, washed with water, and vacuum-dried at 60°C to form a porous apatite carrier;

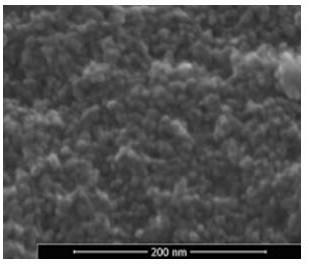

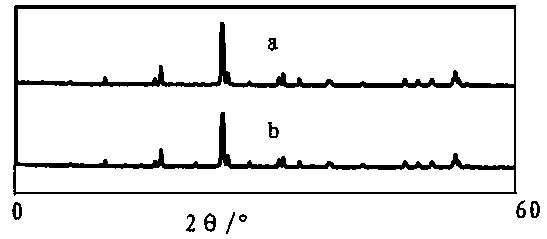

[0037]2) Put 10.0g of porous apatite in ultrapure water, then add nickel nitrate hexahydrate (0.18g, 0.6mmol), zinc nitrate hexahydrate (0.30g, 1mmol) and sodium tungstate dihydrate (0.46g , 1.4mmol) in a hydrothermal kettle at 180-200°C for 6-8h; after the reaction, wash with water until the filtrate becomes neutral, and then roast at 260-300°C for 1-2h to obtain nano-scale nickel salt modified tungsten Zinc acid photocatalytic material, its scanning electron microscope picture is as follows figure 1 As shown, it ca...

Embodiment 2

[0039] Preparation of composite photocatalyst of nickel-doped zinc tungstate:

[0040] Compared with Example 1, the difference is that the addition amount of nickel nitrate hexahydrate is 60 mg, 0.2 mmol, and the rest of the operations are exactly the same as in Example 1.

Embodiment 3

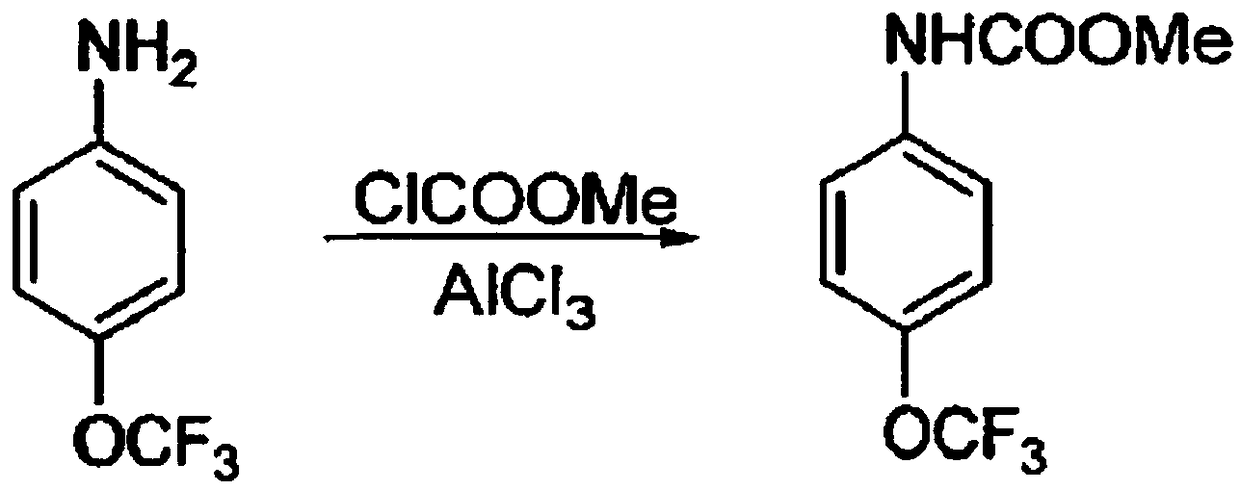

[0074] Although the present invention has higher catalytic activity and versatility, it cannot be recycled; the test results show that after the catalyst recovered by photocatalytic degradation is filtered, washed with water, then dried and reused, the indene of trifluoromethoxyaniline The degradation rate of p-trifluoromethoxyaniline in chorcarb wastewater was reduced from 95.0% (pH=8.0, catalyst dosage 15g / L wastewater) to 58.3%.

[0075] The present invention has attempted following several catalyst activation methods:

[0076] 1) Roasting: the catalyst is filtered and separated, washed with water, and then calcined at 260-300°C for 1-2 hours;

[0077] 2) Pickling / roasting: After the catalyst is filtered and separated, it is soaked in 1mol / L hydrochloric acid aqueous solution and ultrasonicated for 2 hours, and then filtered and roasted at 260-300°C for 1-2 hours;

[0078] 3) Alkaline washing / roasting: After the catalyst is filtered and separated, it is soaked in a 1mol / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com