A kind of sludge solidifying agent and its preparation method and application

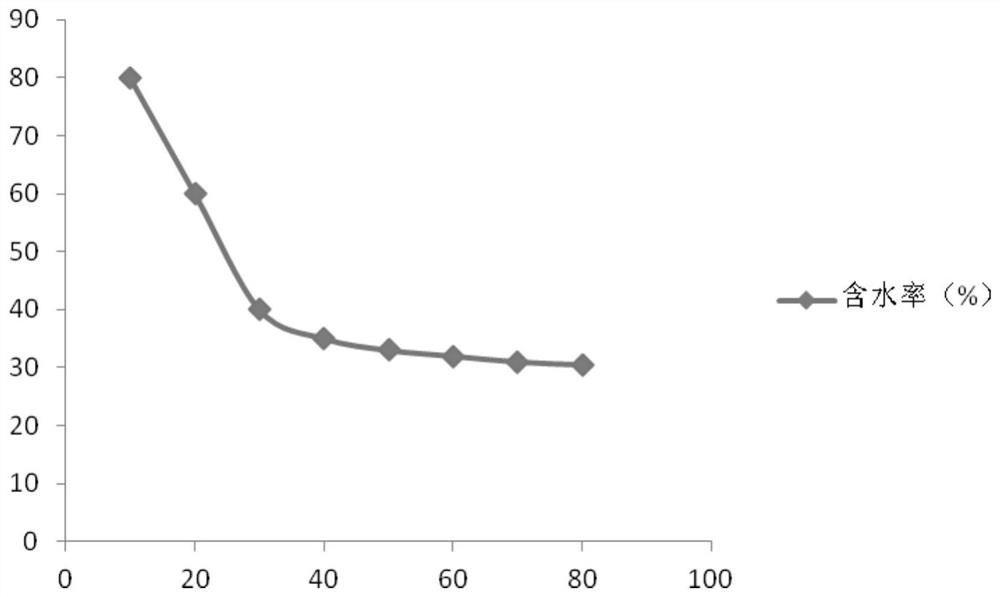

A curing agent and sludge technology, applied in the field of sludge curing agent and its preparation, can solve the problems of landfill engineering geological disasters, high pollutant content, long processing time, etc., achieve short curing time, high efficiency, and reduce moisture content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

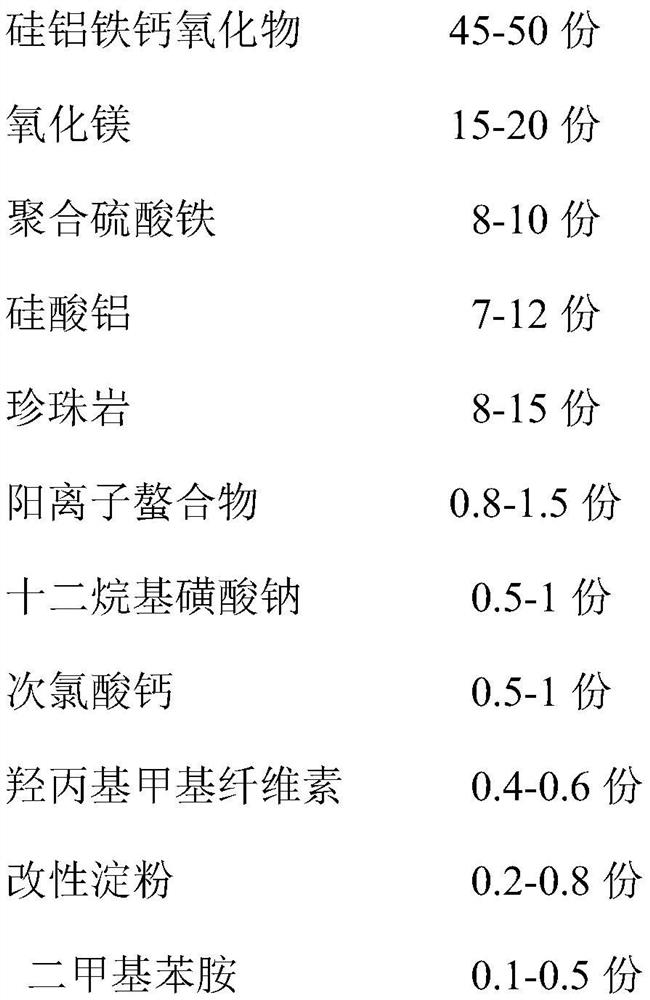

[0032] A preparation method of a sludge solidifying agent, comprising the steps of: (1) using the following parts by weight of each raw material: 45 parts of fine cinder, 20 parts of magnesium oxide, 8 parts of polyferric sulfate, 7 parts of aluminum silicate, 15 parts of perlite 1.5 parts of cationic chelate, 1 part of sodium dodecyl sulfonate, 1 part of calcium hypochlorite, 0.6 part of hydroxypropyl methylcellulose, 0.8 part of modified starch, 0.1 part of dimethylaniline, choose Raw materials, set aside; (2) Fully mix and stir the above-mentioned raw materials in a blender.

[0033] The cationic chelate is formed by chelating ethylenediaminetetraacetic acid (EDTA) and magnesium ions,

[0034] According to the mixing ratio of curing agent and sludge mass ratio of 4%:1, the curing agent is added into the sludge, and then after fully mixing, it can be used after natural drying for 1 hour.

Embodiment 2

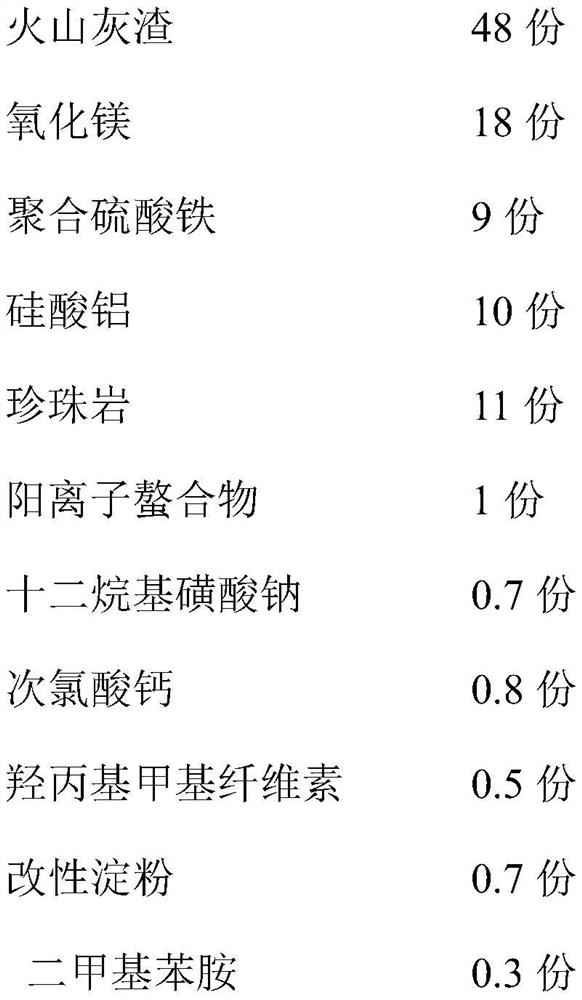

[0036] A preparation method of a sludge solidifying agent, comprising the steps of: (1) using the following parts by weight of each raw material: 48 parts of pozzolan, 18 parts of magnesium oxide, 9 parts of polyferric sulfate, 10 parts of aluminum silicate, and 11 parts of perlite 1 part, 1 part of cationic chelate, 0.7 part of sodium dodecyl sulfonate, 0.8 part of calcium hypochlorite, 0.5 part of hydroxypropyl methylcellulose, 0.7 part of modified starch, 0.3 part of dimethylaniline, choose Raw materials, set aside; (2) Fully mix and stir the above-mentioned raw materials in a blender.

[0037] The cationic chelate is formed by chelating tartaric acid (TA) with iron ions.

[0038] Add the curing agent into the sludge according to the mixing ratio of the curing agent and the sludge mass ratio of 5%:1, and then after fully mixing, let it dry and cure naturally for 0.9 hours before use.

Embodiment 3

[0040] A preparation method of a sludge solidifying agent, comprising the following steps: (1) using the following parts by weight of each raw material: 46 parts of coal gangue, 19 parts of magnesium oxide, 10 parts of polyferric sulfate, 9 parts of aluminum silicate, and 11 parts of perlite 1.2 parts of cationic chelate, 0.9 parts of sodium dodecyl sulfonate, 1 part of calcium hypochlorite, 0.6 parts of hydroxypropyl methylcellulose, 0.8 parts of modified starch, 0.5 parts of dimethylaniline, choose Raw materials, set aside; (2) Fully mix and stir the above-mentioned raw materials in a blender.

[0041] The cationic chelate is formed by chelating aminotriacetic acid (NTA) and calcium ions.

[0042] Add the curing agent into the sludge according to the mixing ratio of the curing agent and the sludge mass ratio of 8%:1, and then after fully mixing, it can be used after natural drying and curing for 0.8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com