A waterborne polyacrylate/polyurethane/sio 2 Preparation method of nanocomposite adhesive

A polyacrylate and nano-composite technology, applied in the directions of graft polymer adhesives, adhesive additives, adhesive types, etc., can solve the problems of adverse effects of adhesive bonding performance, difficulty in ensuring uniform distribution of inorganic particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

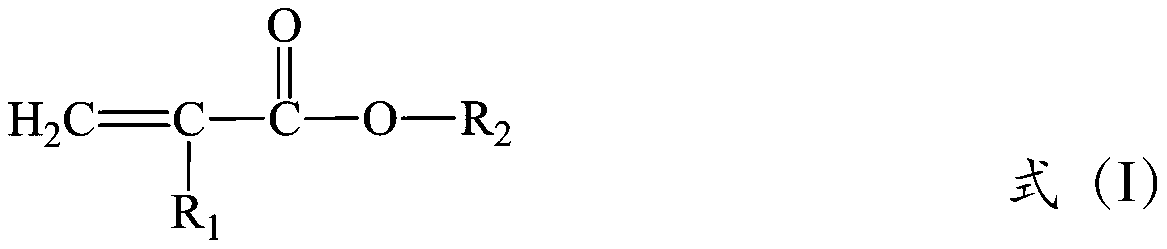

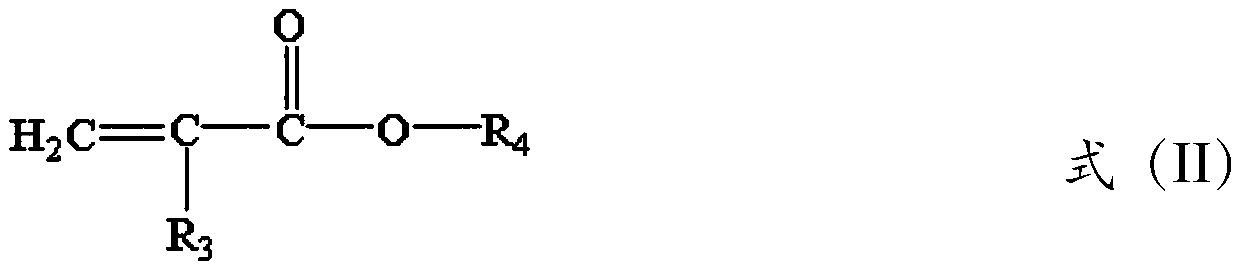

Method used

Image

Examples

Embodiment 1

[0054] Weigh respectively 0.3g of anionic emulsifier sodium lauryl sulfate and 0.5g of pH regulator NaHCO 3 , was dissolved in 55g of water to obtain an emulsifier aqueous solution with a pH value of 8.4.

[0055] 0.1 g of vinyl-modified SiO 2 Nanoparticles [number average particle size is 15nm, coupling density is 3.2 μmol·(m 2 SiO 2 ) -1 】Pre-dispersed in 6g isooctyl acrylate, then with 4g isooctyl acrylate, 0.2g methyl methacrylate, 0.4g methacrylic acid, 0.88g 2-hydroxyethyl acrylate, 1.08g polycaprolactone diol ( The number average molecular weight is 1200g·mol -1 ), 0.45g isophorone diisocyanate, 0.5g octadecyl acrylate and 0.34g n-hexadecane are mixed to obtain SiO 2 monomer dispersion.

[0056] SiO 2 The monomer dispersion is added to the emulsifier aqueous solution, and the coarse emulsion is obtained through pre-emulsification, and then the container containing the coarse emulsion is placed in an ice-water bath, and a stable monomer fine emulsion is obtained b...

Embodiment 2

[0060] Weigh 0.7g of cationic emulsifier octadecyltrimethylammonium bromide, 0.16g of sodium dihydrogen phosphate dihydrate and 0.18g of disodium hydrogen phosphate dihydrate, dissolve them in 70g of water, and obtain emulsification with a pH value of 6.8 agent aqueous solution.

[0061] 0.3 g of vinyl-modified SiO 2 Nanoparticles [number average particle size is 20nm, coupling density is 2.5 μmol·(m 2 SiO 2 ) -1 】Pre-dispersed in 12g butyl acrylate, then mixed with 12g butyl acrylate, 1.6g styrene, 0.06g acrylic acid, 0.7g 2-hydroxypropyl methacrylate, 3.48g polyethylene adipate glycol ( The number average molecular weight is 2100g·mol -1 ), 1.15g of 1,4-cyclohexane diisocyanate, and 1.12g of octadecyl acrylate are mixed to obtain SiO 2 monomer dispersion.

[0062] SiO 2 The monomer dispersion is added to the emulsifier aqueous solution, and the coarse emulsion is obtained through pre-emulsification, and then the container containing the coarse emulsion is placed in an...

Embodiment 3

[0065] Weigh 2.4g of non-ionic emulsifier OP-10 and 0.67g of pH regulator sodium citrate, and dissolve them in 48g of water to obtain an emulsifier aqueous solution with a pH value of 7.8.

[0066] 0.48g SiO 2 Nanoparticles [number-average particle size is 30nm, coupling density is 1.9μmol·(m 2 SiO 2 ) -1 】Pre-dispersed in 10g isooctyl acrylate, then mixed with 2.5g isooctyl acrylate, 0.5g styrene, 0.31g 2-hydroxyethyl methacrylate, 0.73g itaconic acid, 0.7g polyethylene oxide glycol ( The number average molecular weight is 1296 g·mol -1 ), 0.35g 1,6-hexamethylene diisocyanate and 0.80g n-hexadecane are mixed to obtain SiO 2 monomer dispersion.

[0067] Subsequent to SiO 2 Add 0.33g of dibenzoyl peroxide to the monomer dispersion, pre-emulsify to obtain a coarse emulsion, then place the container containing the coarse emulsion in an ice-water bath, and ultrasonically treat it for 5 minutes at a power of 450W to obtain a stable monomer Fine emulsion; after purging nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com