Ultraviolet aging-resistant insulating adhesive

A UV-resistant and insulating adhesive technology, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of limited performance of potting adhesives, and achieve enhanced weather resistance and mechanical properties, good electrical insulation, The effect of improving viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

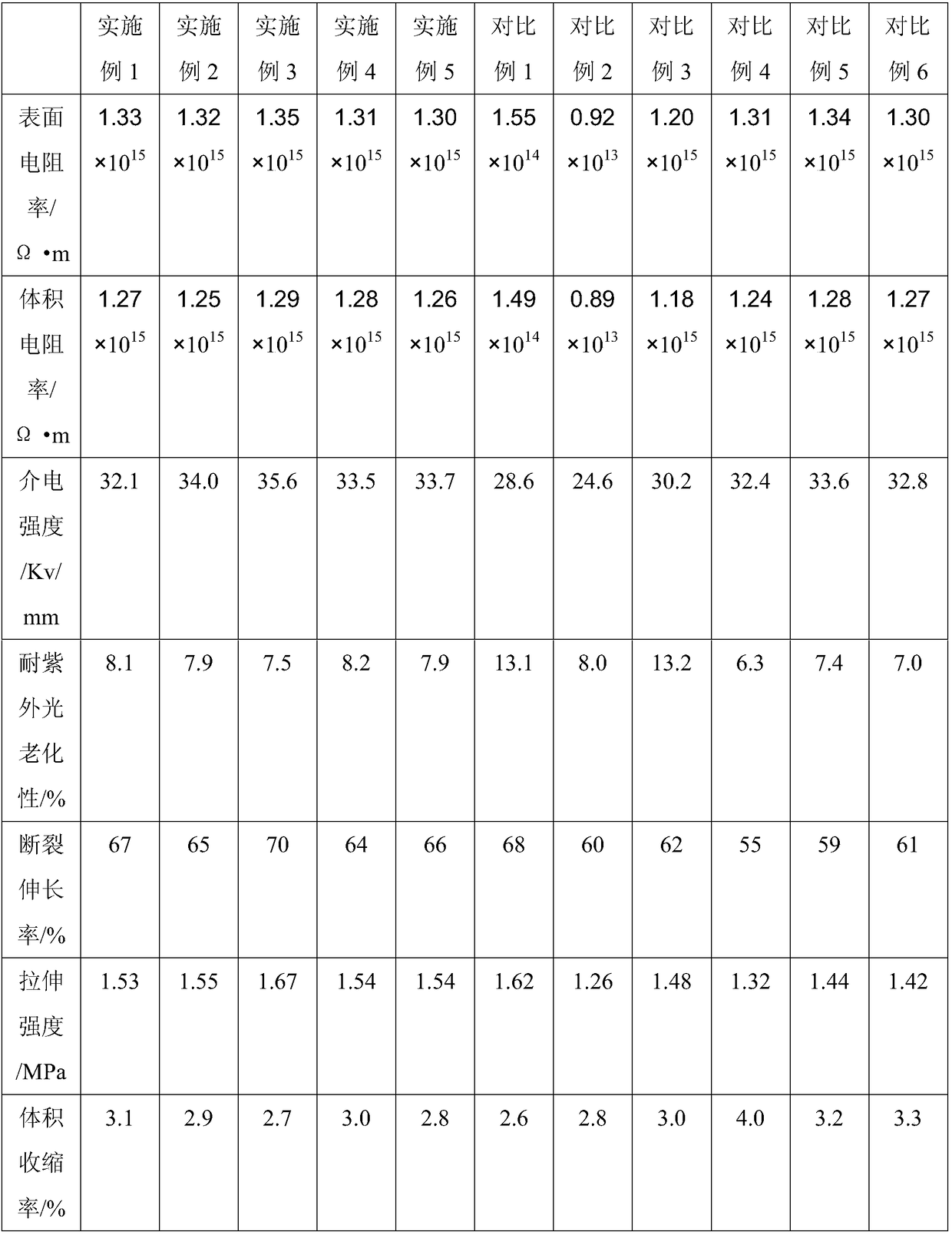

Examples

Embodiment 1

[0021] A kind of anti-ultraviolet light aging insulating glue, by weight, raw material is:

[0022] 15 parts of polytetrafluoroethylene, 4 parts of polymethacrylamide.

[0023] Crosslinking agent: 3 parts of dicumyl peroxide.

[0024] Diluent: 40 parts of methyl ethyl ketone.

[0025] Base resin: 45 parts, wherein the mass ratio of polycarbonate, polystyrene, bisphenol F epoxy resin and phenolic resin is 3:1:6:5.

[0026] Light stabilizer: 5 parts, of which, 2,4-dihydroxybenzophenone, 2-hydroxy-4-n-octyloxybenzophenone and 2-(2'-hydroxy-3',5'-di The mass ratio of tert-phenyl)-5-chlorinated benzotriazole is 1.2:0.8:0.3.

[0027] Antioxidant: Antioxidant THP-24 2.4 parts.

[0028] Filler: 70 parts, wherein the mass ratio of white carbon black, zinc oxide, spherical boron nitride and quasi-spherical aluminum oxide is 3.2:2.4:3.0:1.8, all passed through a 300-mesh sieve.

[0029] The steps for preparing the UV-resistant aging insulating glue are as follows:

[0030] (1) Poly...

Embodiment 2

[0034] A kind of anti-ultraviolet light aging insulating glue, by weight, raw material is:

[0035] 20 parts of polytetrafluoroethylene, 4.7 parts of polymethacrylamide.

[0036] Crosslinking agent: 3.5 parts of di-tert-butyl peroxide.

[0037] Diluent: 47 parts of methyl ethyl ketone.

[0038] Base resin: 53 parts, wherein the mass ratio of polycarbonate, polystyrene, bisphenol F epoxy resin and phenolic resin is 3.5:1.5:7:5.5.

[0039] Light stabilizer: 6 parts, of which, 2,4-dihydroxybenzophenone, 2-hydroxy-4-n-octyloxybenzophenone and 2-(2'-hydroxy-3',5'-di The mass ratio of tert-phenyl)-5-chlorinated benzotriazole is 1.35:0.95:0.4.

[0040] Antioxidant: Antioxidant THP-EPQ 2.7 parts.

[0041]Filler: 80 parts, wherein the mass ratio of white carbon black, zinc oxide, spherical boron nitride and quasi-spherical aluminum oxide is 3.8:2.9:3.5:1.85, all passing through a 300-mesh sieve.

[0042] The steps for preparing the UV-resistant aging insulating glue are as follows...

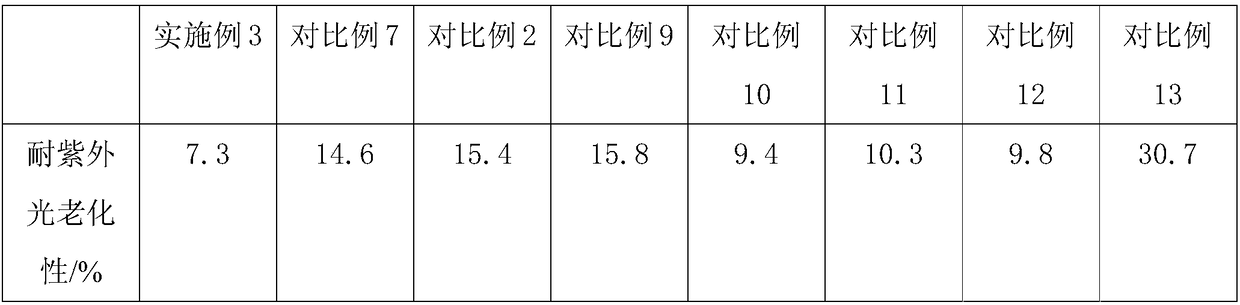

Embodiment 3

[0047] A kind of anti-ultraviolet light aging insulating glue, by weight, raw material is:

[0048] 25 parts of polytetrafluoroethylene, 5.5 parts of polymethacrylamide.

[0049] Cross-linking agent: 4 parts of dicumyl peroxide.

[0050] Diluent: 55 parts of n-butanol.

[0051] Base resin: 60 parts, wherein the mass ratio of polycarbonate, polystyrene, bisphenol F epoxy resin and phenolic resin is 4:2:8:6.

[0052] Light stabilizer: 7 parts, of which, 2,4-dihydroxybenzophenone, 2-hydroxy-4-n-octyloxybenzophenone and 2-(2'-hydroxy-3',5'-di The mass ratio of tert-phenyl)-5-chlorinated benzotriazole is 1.5:1.1:0.5.

[0053] Antioxidant: 3.0 parts of tris(nonylphenol) phosphite.

[0054] Filler: 90 parts, wherein the mass ratio of white carbon black, zinc oxide, spherical boron nitride and quasi-spherical aluminum oxide is 4.5:3.5:4.0:1.9, all passed through a 300-mesh sieve.

[0055] The steps for preparing the UV-resistant aging insulating glue are as follows:

[0056] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com