Method of preparing dual-function catalyst having oxygen reduction and oxygen separation activities by using biomass tar

A dual-function catalyst and biomass technology, applied in electrical components, battery electrodes, circuits, etc., to achieve good stability, strong catalytic activity, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

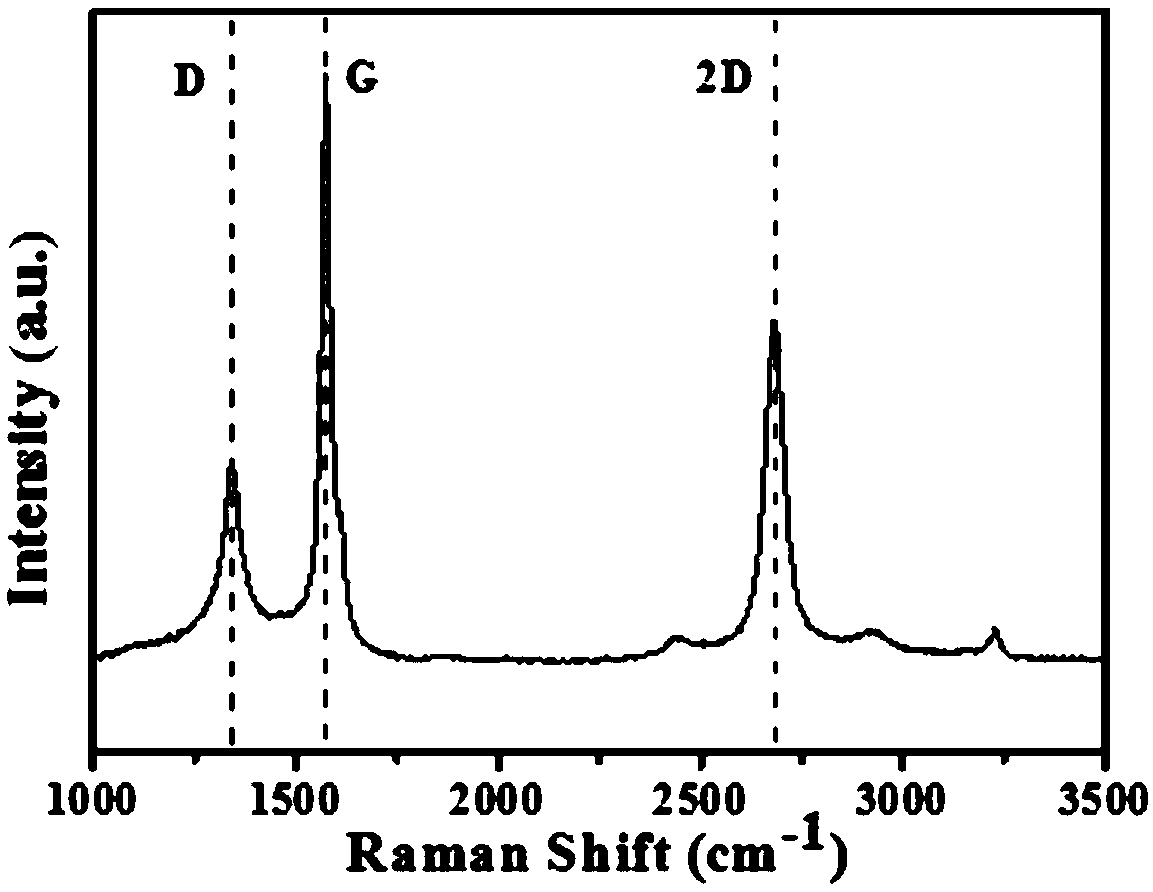

Image

Examples

Embodiment 1

[0024] Disperse 8g of biomass tar in 50ml of deionized water, add 24g of potassium hydroxide, ultrasonicate for 30min, and stir at room temperature for 10min to obtain mixed solution 1. Dissolve 24g of F127 in 100ml of deionized water and stir for 1h at room temperature to obtain solution 2. Solution 1 and Solution 2 were mixed, stirred at room temperature for 4 h, and dried at 100° C. for 24 h. The dried sample was pyrolyzed at 2°C / min at 900°C under a nitrogen atmosphere, and the reaction residence time was 3h. After the reaction, it was naturally cooled to room temperature to obtain a porous carbon material. The obtained porous carbon material was mixed with 150ml of 10wt% hydrochloric acid solution, acid-washed at room temperature for 24 hours, then the solution was filtered, washed with deionized water until neutral, and dried at 100°C for 24 hours. The dried sample was calcined at 900°C at 10°C / min under an ammonia atmosphere, and the residence time was 0.5h to obtain th...

Embodiment 2

[0030] Referring to Example 1, the difference is that the dried sample is calcined at 900° C. at 10° C. / min under an ammonia atmosphere, and the residence time is 1 h.

[0031] Catalyst activity test and stability test are the same as in Example 1, the measured starting voltage is -0.05V, and the limiting diffusion current density is -4.77mA / cm 2 .

Embodiment 3

[0033] Referring to Example 1, the difference is that the dried sample is calcined at 1000°C at 10°C / min under an ammonia atmosphere, and the residence time is 0.5h.

[0034] Catalyst activity test and stability test are the same as in Example 1, the measured starting voltage is -0.05V, and the limiting diffusion current density is -4.90mA / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com