Preparation method of cobalt sulfide/three-dimensional nitrogen-doped macroporous graphene and negative electrode material of lithium ion battery

A nitrogen-doped, graphene technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problem of easy decay of discharge capacity, and achieve excellent structural stability, short synthesis period, and stress relief effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

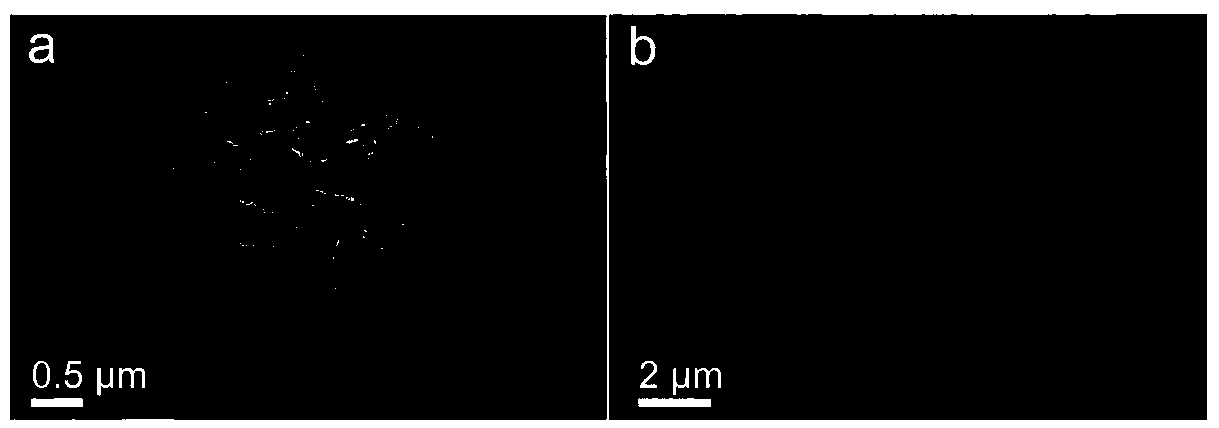

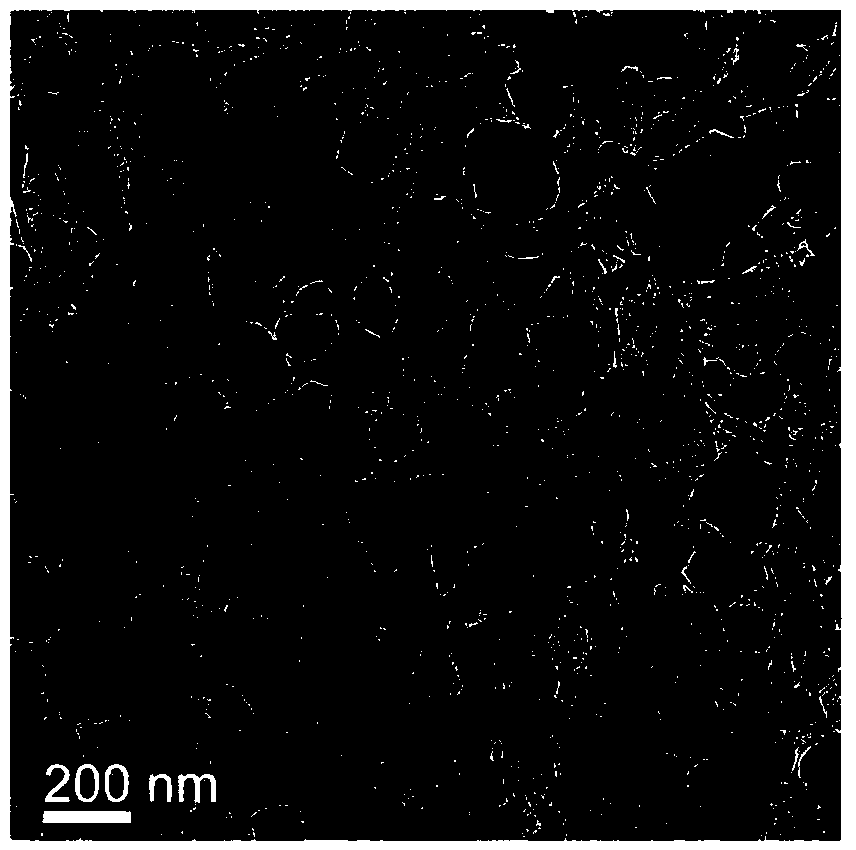

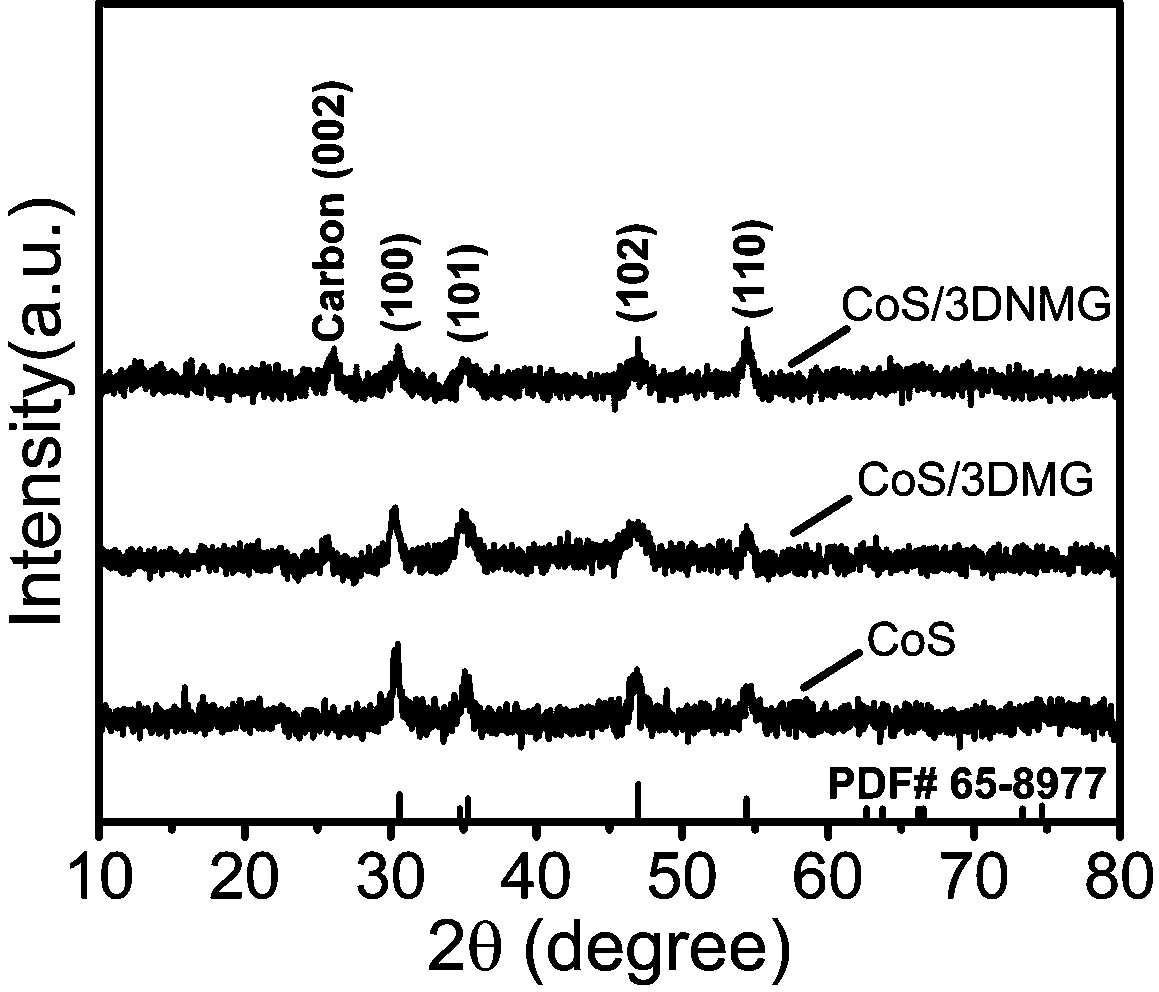

Image

Examples

Embodiment 1

[0030] First prepare three-dimensional nitrogen-doped macroporous graphene:

[0031] Dissolve 120.0 mg of graphene oxide in 60 ml of deionized water, and ultrasonically disperse at 40 KHz for 10 min, then add 0.3 g of urea to the above solution, continue ultrasonically dispersing for 2 h, and then quickly transfer it to In a 100 ml polytetrafluoroethylene-lined stainless steel autoclave, set the temperature at 180 °C, and the reaction time is 12 h. After the reaction, cool to room temperature, take out the solid phase and freeze-dry for 36 h, and finally place it in a tubular high-temperature sintering furnace Calcined at 800 °C for 2 h under the protection of argon to obtain three-dimensional nitrogen-doped macroporous graphene,

[0032] 2. Preparation of CoS / 3DNMG composites:

[0033] (a) Weigh 0.2379 mg of cobalt chloride hexahydrate CoCl 2 •6H 2 O and 0.3045 mg of thiourea CS(NH 2 ) 2 Add in 30.0 mL of a mixed solvent of ethylene glycol and water (volume ratio 1:4), a...

Embodiment 2

[0044] In this example, the CoS / 3DNMG composite material prepared in Example 1 and the CoS / 3DMG and CoS / 3DNMG prepared in Comparative Example were used as electrode active materials to carry out fabrication of lithium-ion electrodes, assembly of lithium-ion batteries and performance testing.

[0045] Using NMP as solvent, CoS / 3DNMG composite material was prepared from the prepared example as active material, acetylene black as conductive agent, PVDF as binder, the mass ratio of the three components was 8:1:1, magnetic stirring 8 h Prepare the slurry, and use the coating machine to evenly coat the prepared slurry on the copper foil, and keep it at 80 °C for 10 h. After drying, it was cut into CoS / 3DNMG electrode sheets with a microtome, and then vacuum-dried at 120 °C for 12 h to remove a small amount of moisture. After the electrode piece is weighed, it is directly used as the negative electrode of the lithium-ion battery to assemble the 2032-type button battery in an argon-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com