Sulfur tail gas hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and tail gas technology, applied in the direction of sulfur preparation/purification, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of poor anti-coking performance and poor oxygen resistance of catalysts , pollute the environment and other issues, and achieve the effects of strong antioxidant capacity, significant economic and social benefits, and high water vapor content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

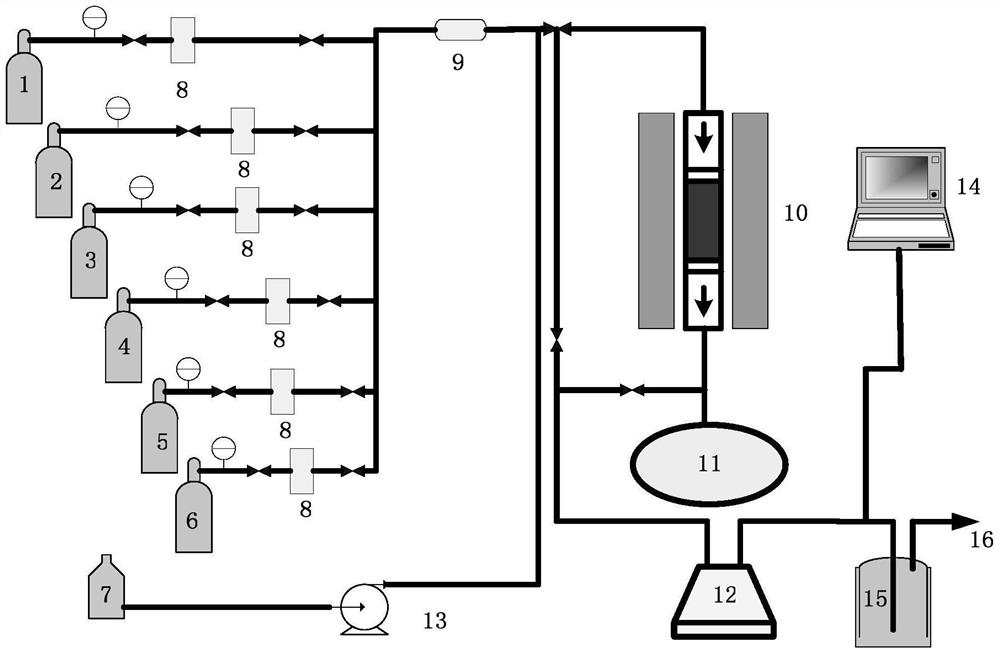

Method used

Image

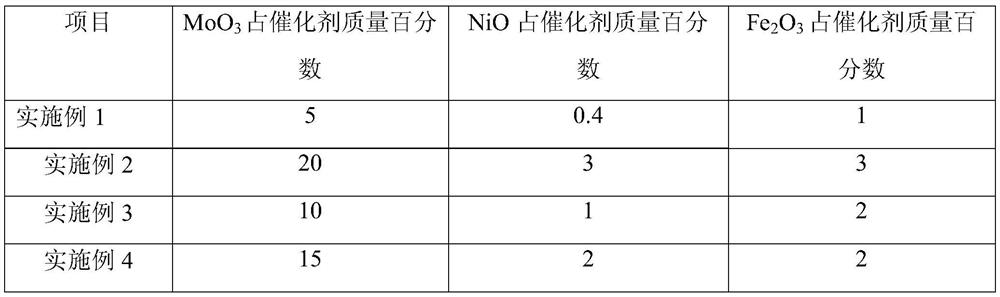

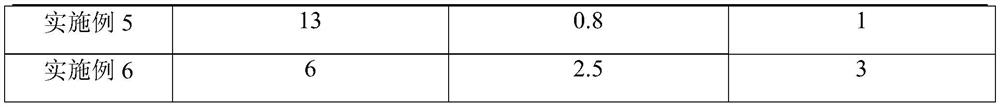

Examples

Embodiment 1

[0037] Put the diatomite in 95°C water and stir to remove the sediment, lower the temperature to 5°C, treat it with 20% phosphoric acid at an acid / soil ratio of 1 for 5 hours, filter, dry, and roast at 400°C to obtain modified diatomite.

[0038] Get 25 grams of above-mentioned modified diatomite, pseudo-boehmite (specific surface area is 300m 2 / g) 200 grams, 3 grams of calcium oxide, 4 grams of asparagus powder, 28 grams of nitric acid, 11.22 grams of ferric nitrate nonahydrate dissolved in 270 grams of deionized water and mixed evenly, extruded on the extruder, and dried at 120 ° C 4 hours, and calcined at 500° C. for 4 hours to obtain a catalyst carrier.

[0039] Take 5ml of phosphoric acid and add it to 80ml of deionized water, mix 1.34g of basic nickel carbonate and 10g of molybdenum trioxide evenly, add it into the aqueous solution containing phosphoric acid, stir until it is completely dissolved, impregnate the carrier with equal volume of the above immersion solution ...

Embodiment 2

[0045] Put the diatomite in 95°C water and stir to remove the sediment, lower the temperature to 15°C, treat it with 25% phosphoric acid at an acid / soil ratio of 1 for 8 hours, filter, dry, and roast at 450°C to obtain modified diatomite.

[0046] Get above-mentioned modified diatomite 20 grams, pseudo-boehmite (specific surface area is 300m 2 / g) 180 grams, 3 grams of barium oxide, 4 grams of asparagus powder, 28 grams of nitric acid, 33.66 grams of ferric nitrate nonahydrate dissolved in 263 grams of deionized water, mixed evenly, extruded on the extruder, and dried at 120 ° C 4 hours, calcined at 550° C. for 4 hours to obtain a catalyst carrier.

[0047] Take 5ml of phosphoric acid and add it to 80ml of deionized water, mix 10.05g of basic nickel carbonate and 40g of molybdenum trioxide evenly, add it into the aqueous solution containing phosphoric acid, stir until it is completely dissolved, impregnate the carrier with an equal volume of the above immersion solution for 2 ...

Embodiment 3

[0053] Put the diatomite in 95°C water and stir to remove the sediment, lower the temperature to 40°C, treat it with 40% phosphoric acid at an acid / soil ratio of 1 for 12 hours, filter, dry, and roast at 600°C to obtain modified diatomite.

[0054] Get above-mentioned modified diatomite 20 grams, pseudo-boehmite (specific surface area is 300m 2 / g) 190 grams, 3 grams of calcium oxide, 8ml polyethylene glycol, 28 grams of nitric acid, 22.44 grams of ferric nitrate nonahydrate dissolved in 267 grams of deionized water and mixed evenly, extruded on the extruder, dried at 120 ° C 4 hours, and calcined at 500° C. for 6 hours to obtain a catalyst carrier.

[0055] Take 5ml of citric acid and add it to 80ml of deionized water, mix 3.35g of basic nickel carbonate and 24.52g of ammonium heptamolybdate tetrahydrate evenly, add it to the aqueous solution containing citric acid, stir until it is completely dissolved, and impregnate the carrier with an equal volume of the above immersion s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com