Method for synthesizing nano GaZSM-5 silicon gallate molecular sieve through dry glue conversion method

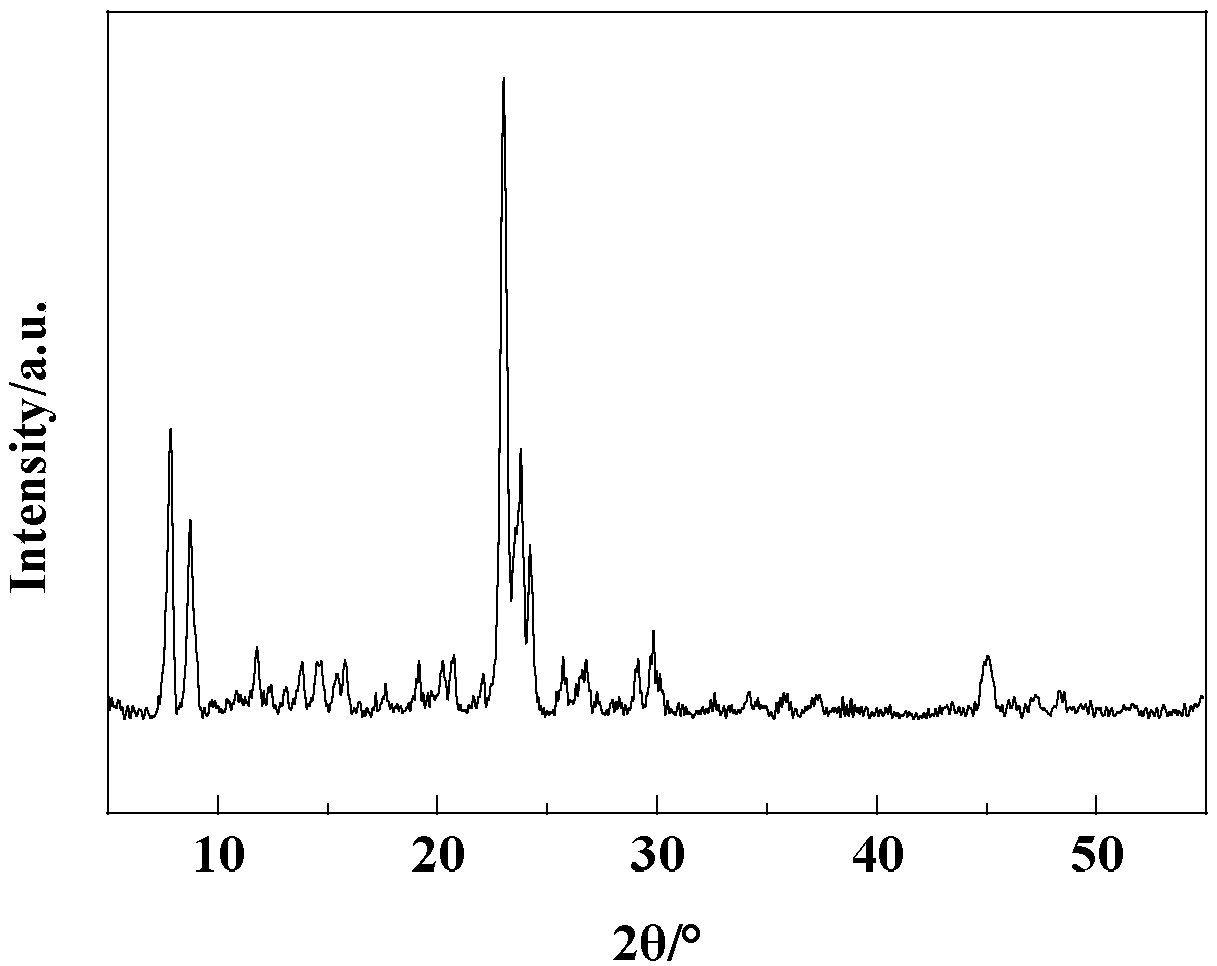

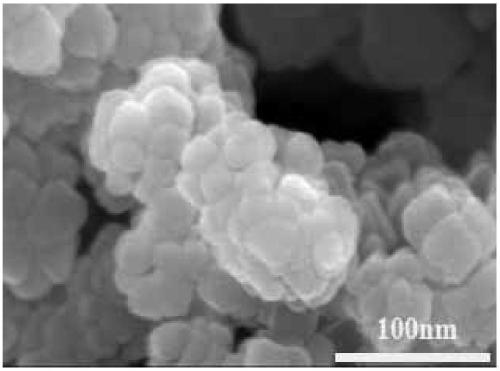

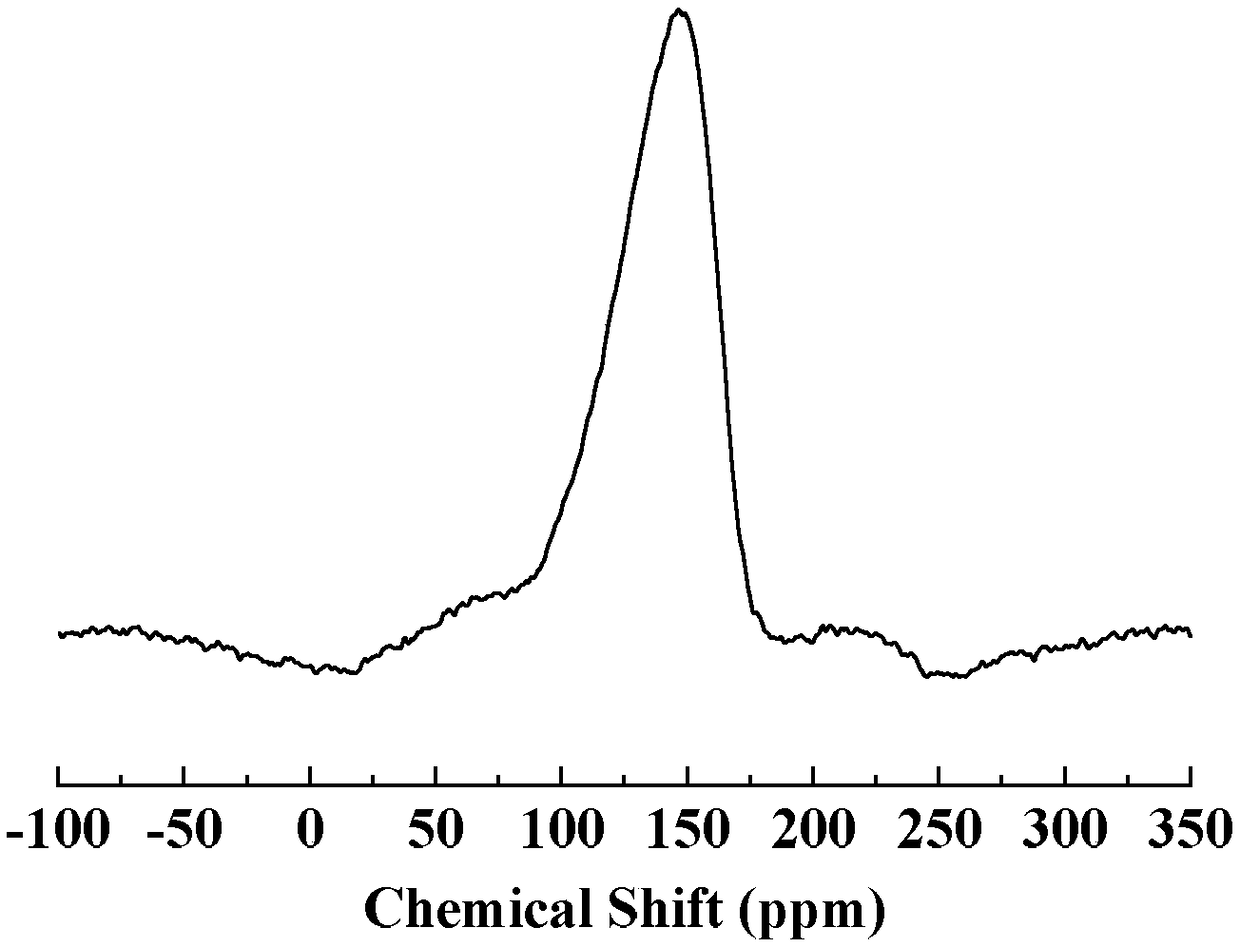

A technology for the conversion of gallosilicate and dry gel, which is applied in the direction of gallosilicate, crystalline aluminosilicate zeolite, nanotechnology, etc., can solve the problems of large particle size and poor mass transfer capacity of molecular sieves, and achieve crystallization Effect of short time, high crystallinity, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific implementation mode one: the method for synthesizing nano-GaZSM-5 silicate gallate molecular sieve by dry glue conversion method in this embodiment is implemented according to the following steps:

[0025] 1. Weigh 1 part of gallium trioxide, 84.8 to 141.3 parts of tetrapropylammonium hydroxide aqueous solution, 110.0 to 182.4 parts of deionized water and 136.1 to 226.7 parts of ethyl orthosilicate in parts by weight as raw materials;

[0026] The mass fraction of tetrapropylammonium hydroxide in the tetrapropylammonium hydroxide aqueous solution is 50%~55%;

[0027] 2. Add tetrapropylammonium hydroxide aqueous solution and deionized water to the digallium trioxide weighed in step 1, and place it in a closed stainless steel reaction kettle with a polytetrafluoroethylene liner at 155-165°C Cool down to 25°C after 2.5-3.5 hours of down treatment to make a reaction solution;

[0028] 3. Add the tetraethyl orthosilicate weighed in step 1 dropwise into the reaction...

specific Embodiment approach 2

[0032] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the mass fraction of tetrapropyl ammonium hydroxide in the tetrapropyl ammonium hydroxide aqueous solution in step 1 is 54%-55%.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the mass fraction of tetrapropyl ammonium hydroxide in the tetrapropyl ammonium hydroxide aqueous solution in step one is 54.78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com