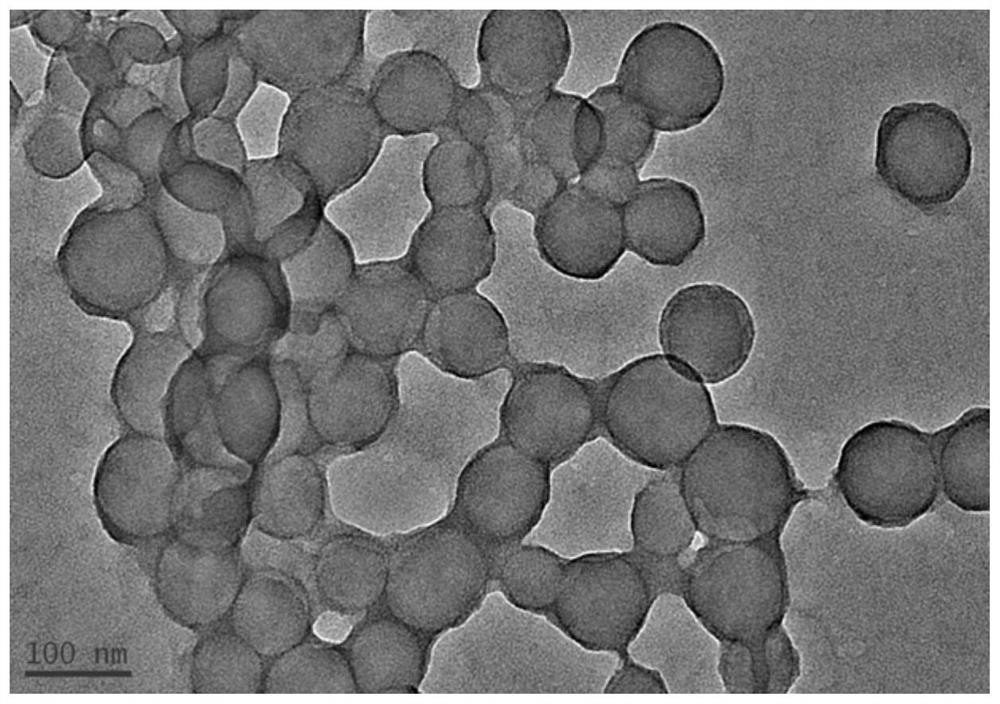

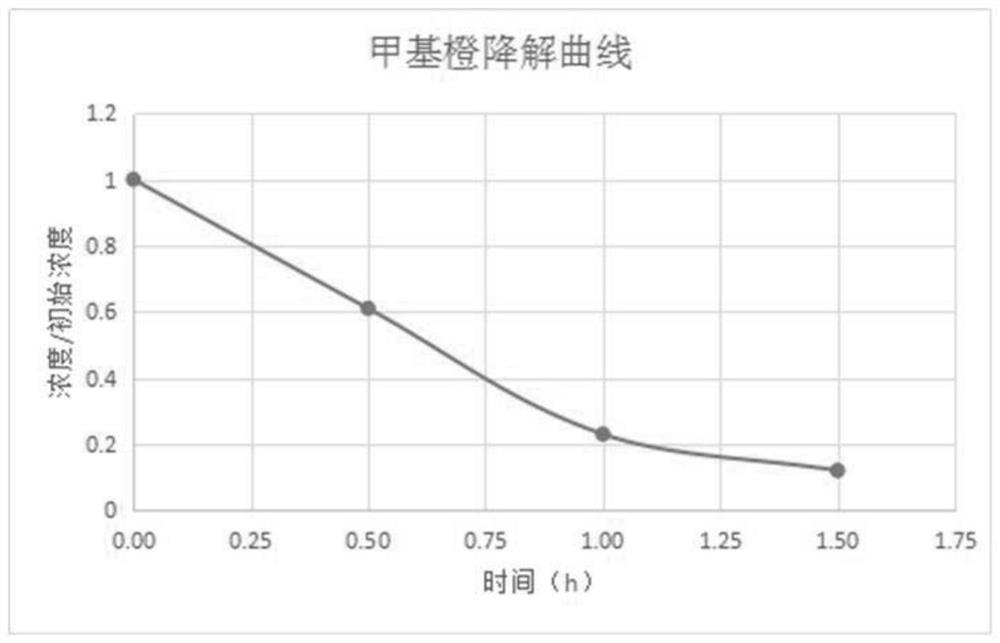

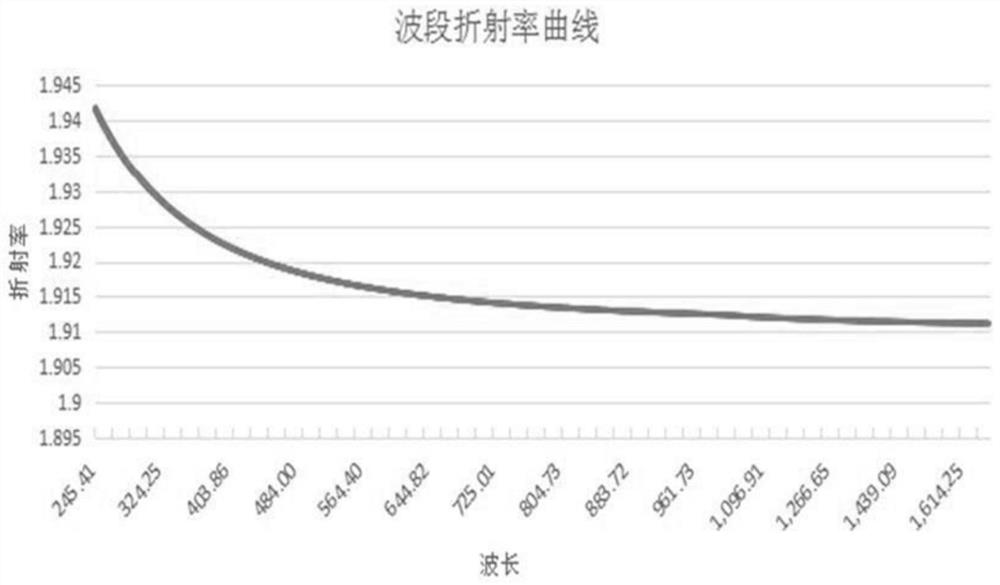

Nano hollow titanium dioxide microspheres with low refractive index and high catalytic activity and preparation method thereof

A high catalytic activity, titanium dioxide technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of high catalytic activity, adhesion deformation, low refractive index, etc., achieve high catalytic activity and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of nano-titanium dioxide hollow microsphere with low refractive index and high catalytic activity of the present embodiment is prepared by the following steps (the following components are all by mass percentage):

[0040] Step a, add 73.4% water to the reaction vessel, start stirring and heating, when the temperature rises to 85°C, add 2% ammonium persulfate initiator solution, after the temperature stabilizes, start to add 18% styrene, 0.6% of divinylbenzene, 2% of cationic monomer acryloyloxyethyltrimethoxyammonium chloride and 4% of zwitterionic reactive emulsifier SM-JR-1 were added within 6 hours and kept for reaction 10h; After the heat preservation is completed, cool down to 30°C, add additive ammonia water to neutralize, adjust the pH value to 8, and then filter to obtain a cationic polystyrene emulsion;

[0041] Step b, mix 5% cationic polystyrene emulsion and 81% solvent methanol evenly, and mix 12% titanium source isopropyl titanate and 2% chelating a...

Embodiment 2

[0045] A kind of nano-titanium dioxide hollow microsphere with low refractive index and high catalytic activity of the present embodiment is prepared by the following steps (the following components are all by mass percentage):

[0046] Step a, add 64% water to the reaction vessel, start stirring and heating, when the temperature rises to 135°C, add the initiator solution of 2% potassium persulfate and 3% sodium persulfate, after the temperature stabilizes, start adding 20% styrene, 1% divinylbenzene, cationic monomers 4% methacryloxyethyltrimethylammonium chloride and 1% acrylamidopropyltrimethylammonium chloride, and 5% The zwitterionic reactive emulsifier SM-JR-1 was added within 4 hours, and kept for 6 hours; after the heat preservation was completed, the temperature was lowered to 33°C, and the auxiliary agent diethanolamine was added to neutralize, and the pH value was adjusted to 7, and then filtered Obtain cationic polystyrene emulsion;

[0047] Step b, mix 2% cationi...

Embodiment 3

[0050] A kind of nano-titanium dioxide hollow microsphere with low refractive index and high catalytic activity of the present embodiment is prepared by the following steps (the following components are all by mass percentage):

[0051] Step a, add 87.4% water to the reaction vessel, start stirring and heating, when the temperature rises to 60°C, add 0.5% benzoyl peroxide initiator solution, after the temperature stabilizes, start adding 10% benzene Ethylene, 0.1% divinylbenzene, cationic monomer 0.5% benzylvinyltrimethylammonium chloride and 0.5% methacryloyloxyethyldimethylbenzylammonium chloride, and 1% amphoteric The ion-reactive emulsifier SM-JR-1 was added within 8 hours, and kept for 13 hours. After the heat preservation was completed, the temperature was lowered to 37°C, and the additives triethanolamine and triethylamine were added for neutralization, and the pH value was adjusted to 4. Then filter to obtain cationic polystyrene emulsion;

[0052] Step b, mix 10% cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com