Comprehensive utilization method for tributoxy ethyl phosphate wastewater

A technology of tributoxyethyl phosphate and waste water, which is applied in the direction of chemical instruments and methods, compounds of group 5/15 elements of the periodic table, water pollutants, etc., and can solve the problem of high equipment failure shutdown rate and scaling on the inner wall of equipment , can not remove phosphorus and other problems, to achieve the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

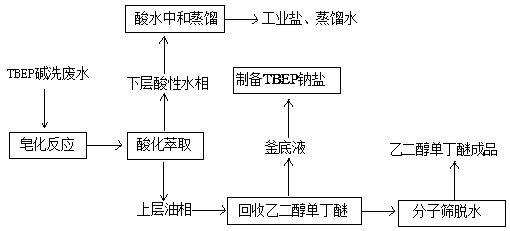

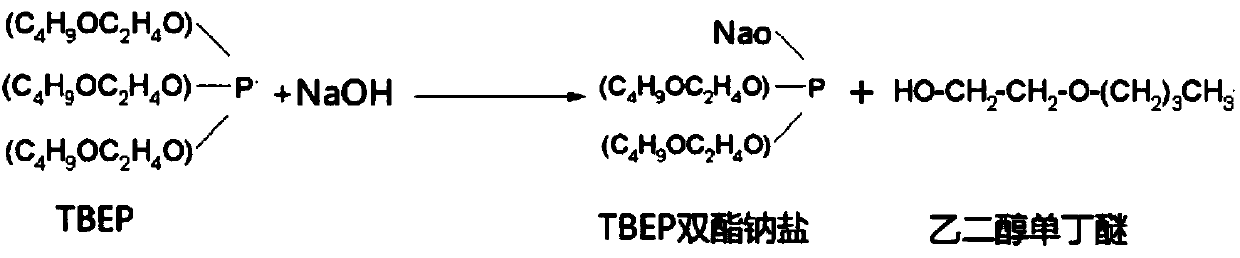

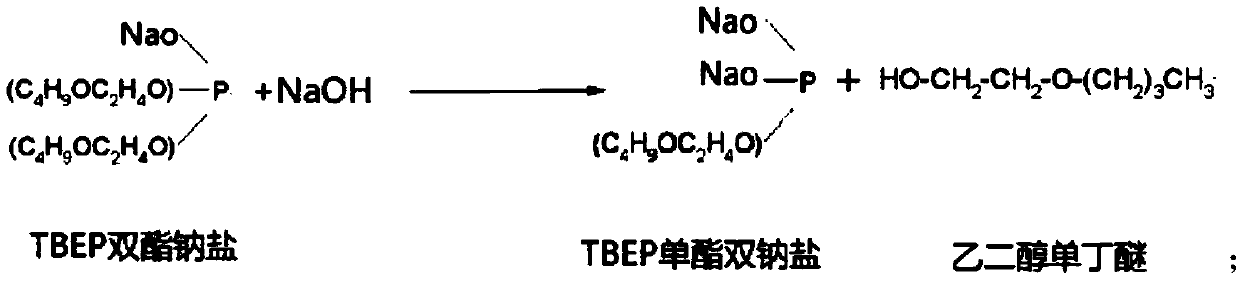

Method used

Image

Examples

Embodiment 1

[0048] Wastewater: TBEP production alkaline washing wastewater, after analysis: total phosphorus = 14058.7ppm, COD = 112965.3mg / L, pH = 9, sodium chloride 0.0347%, ethylene glycol monobutyl ether 4.85%, TBEP 6.04%, TBEP double Ester sodium salt is 9.2%, and the appearance is colorless and transparent liquid after precipitation and filtration.

[0049] A method for treating tributoxyethyl phosphate wastewater, the steps are as follows:

[0050] 1) Saponification reaction: Stir 330 kg of TBEP alkaline washing wastewater in the reactor to increase the temperature to 85°C, add 30% sodium hydroxide aqueous solution under stirring, and control the pH value of the wastewater in the reactor to maintain 8-9 (total add hydroxide Sodium aqueous solution 10.47kg), the saponification reaction is terminated after 3 hours of heat preservation and the saponification wastewater is obtained;

[0051] 2) Acidification extraction: Step 1) Keep the temperature of the saponification wastewater at 85°C, d...

Embodiment 2

[0057] Example 2: A method for treating tributoxyethyl phosphate wastewater. The method conditions are the same as those in Example 1, but different from Example 1. In step 2), the acidification pH is controlled at 3-4, and it is found that the saponification wastewater In an emulsified state where no stratification is possible, it is considered that TBEP sodium salt has not reacted to TBEP hydroxyl compound.

Embodiment 3

[0058] Example 3: A method for treating tributoxyethyl phosphate wastewater. The method conditions are the same as in Example 1, but different from Example 1. In step 2), the acidification PH value is controlled below 1 and the acidity of the lower layer is sampled. Water phase COD=359.1mg / L, considering the detection error, it can be considered that the result is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com