Piezoelectric-photocatalyst for enhancing photocatalytic degradation reaction, preparation method and application thereof

A photocatalyst and degradation reaction technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., can solve secondary pollution, energy consumption, increase Catalyst cost and other issues, to achieve the effect of increasing rate and mineralization degree, and stabilizing chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a piezoelectric-photocatalyst for enhancing photocatalytic degradation reaction, comprising the following steps:

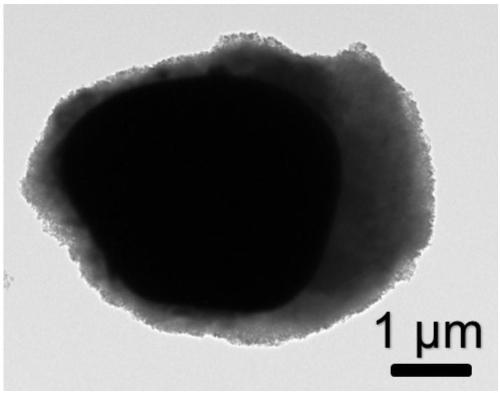

[0028] (1) Preparation of piezoelectric material lead zirconate titanate powder: mix zirconia, titanium oxide, and lead oxide mixed powders according to the molar ratio of lead element, zirconium element, and titanium element for 6 hours by ball milling at 800 ° C and 1200 °C respectively. ℃ Calcination 2h. After crushing, the lead zirconate titanate powder with a spherical structure can be obtained, and the lead zirconate titanate powder with a spherical structure can be obtained;

[0029] (2) Disperse 0.4g of lead zirconate titanate powder in 120mL of absolute ethanol, disperse in an ultrasonic bath for 15min, then add 2mL of concentrated ammonia water, and then add 2.0mL of tetrabutyl titanate dropwise, and transfer the above mixed liquid to In a 200mL stainless steel sealed hydrothermal kettle, place it in an oil bath at 110°C a...

Embodiment 2

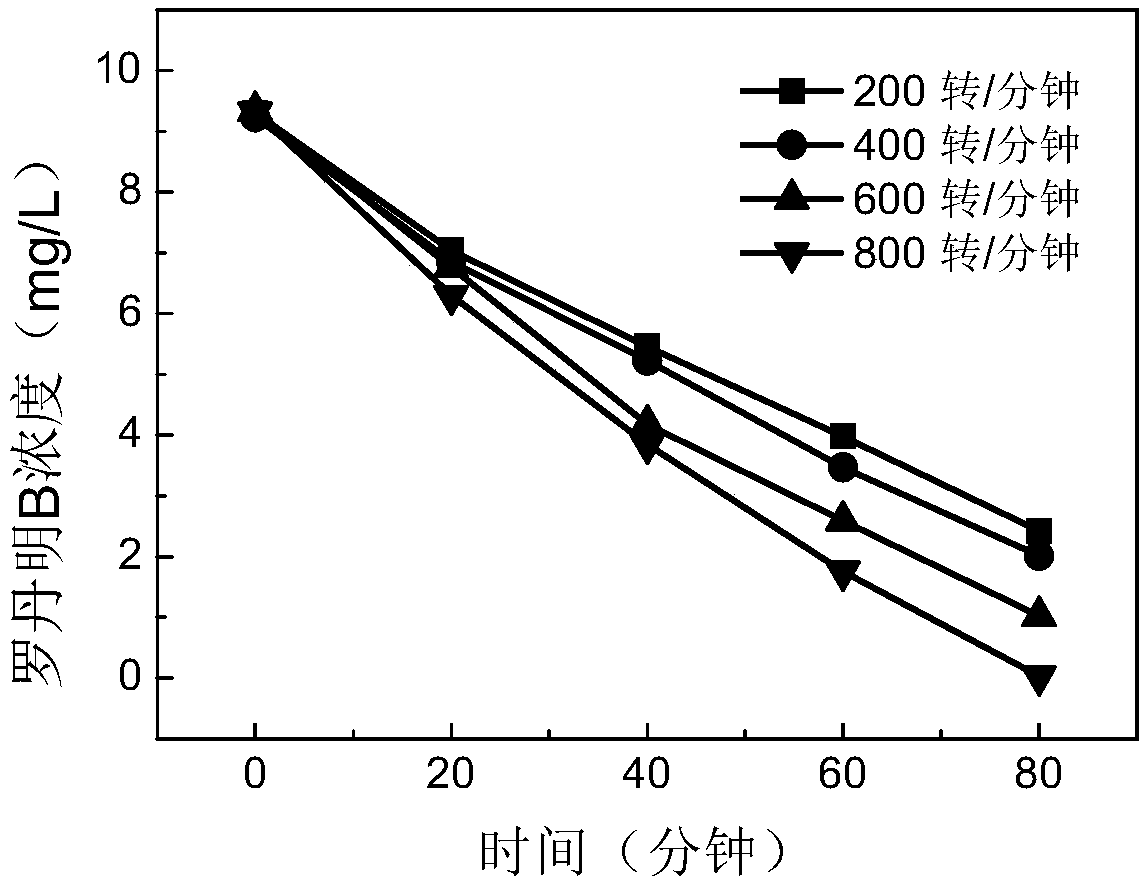

[0033] The piezoelectric-photocatalyst obtained in Example 1 was dispersed in a 10 mg / L rhodamine B dye solution so that its mass fraction was 2 g / L.

[0034] like image 3 , given at 15mW·cm -2 The test results of photocatalytic degradation of Rhodamine B at stirring rates of 200, 400, 600 and 800rpm under ultraviolet light irradiation showed that the stronger piezoelectric field induced by higher stirring rates can promote the photocatalytic reaction.

Embodiment 3

[0036] The operation steps of Example 2 were repeated, except that the detection target was the total organic carbon content in the solution. The result was similar to that of Example 1, and the total organic carbon content was significantly reduced as the stirring intensity increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com