A method for preparing composite phosphating film by doping inorganic nanoparticles

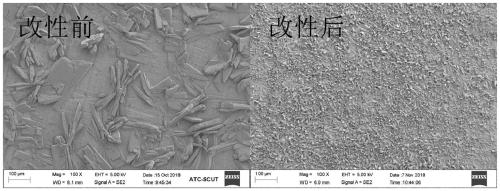

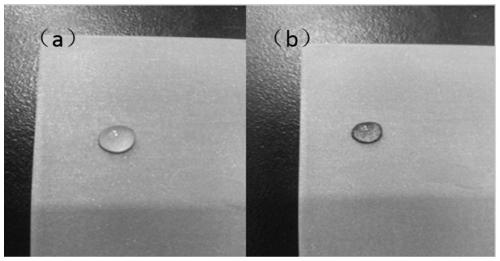

A technology of inorganic nanoparticles and phosphating film, applied in the field of material science and surface, can solve the problems affecting the quality, output and cost of coating production, poor quality of phosphating film, high cost, etc., and achieve excellent oxidation resistance and chemical Stability, reduction of phosphating treatment temperature, effect of film hardness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

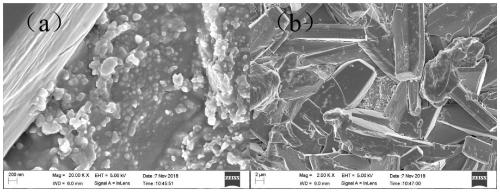

[0044] In parts by weight, weigh the following raw material components: 5 parts of zinc dihydrogen phosphate dihydrate, 7 parts of zinc nitrate hexahydrate, 0.6 parts of phosphoric acid, hexagonal boron nitride (average particle size 100 nanometers, powder shape is oval Shape or disc shape, with short axis La and long axis L b And the thickness t satisfies: 80nm≤La≤L b ≤700nm, 20nm≤t≤150nm, t≤La, 0.5≤La / L b ≤1.0) 0.1 part, linear alkyl benzene sulfonate (LAS) 0.2 part, potassium chloride-hydrochloric acid pH buffer solution 6 parts, water 100 parts. Then put the components into the reaction kettle, adjust the pH of the solution in the kettle to 2.3 with lye, and raise the temperature to 30°C. Then control the stirring speed at 300 rpm, and leave the kettle after 30 minutes of mechanical stirring. Then put the prepared phosphating treatment solution into the phosphating tank, immerse the surface-treated steel test piece in it, and rinse it with water for 20 minutes to dry it to ...

Embodiment 2

[0054] Take the following raw material components according to the weight ratio: 8 parts of zinc phosphate, 4 parts of zinc chloride, 3 parts of zinc nitrate, 2.5 parts of phosphoric acid, cubic boron nitride (average particle size 50 nanometers, powder shape is elliptical disc or round Disk shape, short axis La, long axis L b And the thickness t satisfies: 80nm≤La≤L b ≤700nm, 20nm≤t≤150nm, t≤La, 0.5≤La / L b ≤1.0) 0.08 parts, fatty alcohol polyoxyethylene ether sodium sulfate (AES) 0.2 parts, aminoacetic acid-hydrochloric acid PH buffer solution 6 parts, water 100 parts. Put each component into the reaction kettle, adjust the pH of the solution in the kettle to 2.7 with lye, and raise the temperature to 30°C. Then control the stirring speed at 250 rpm, and leave the kettle after 30 minutes of mechanical stirring. Put the prepared phosphating treatment solution into the phosphating tank, and then immerse the surface-treated steel specimens in it for a treatment time of 15 minutes...

Embodiment 3

[0057] Take the following raw material components according to the weight ratio: 7 parts of zinc phosphate, 6 parts of zinc nitrate hexahydrate, 1 part of phosphoric acid, hexagonal boron nitride (average particle size 80 nm, powder shape is elliptical disc or disc, and Short axis La, long axis L b And the thickness t satisfies: 80nm≤La≤L b ≤700nm, 20nm≤t≤150nm, t≤La, 0.5≤La / L b ≤1.0) 0.06 parts, 0.2 parts of alkylphenol polyoxyethylene ether (APEO) emulsifier, 7 parts of monochloroacetic acid-sodium hydroxide pH buffer, and 100 parts of water. Put the components into the reaction kettle, adjust the pH of the solution in the kettle to 2.5 with lye, and then raise the temperature to 28°C. Then control the stirring speed at 200 rpm, and leave the kettle after 30 minutes of mechanical stirring. Put the prepared phosphating treatment solution into the phosphating tank, immerse the surface-treated steel test piece in it, and rinse it with water for 10 minutes to dry it to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com