Composite shell material microcapsule with double anti-corrosion function and preparation method thereof

A microcapsule and anti-corrosion technology, which is applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of no corrosion inhibition, poor compatibility between microcapsules and the matrix, and achieve uniform particle size distribution of the emulsion. Effect of improving toughness and mechanical strength and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

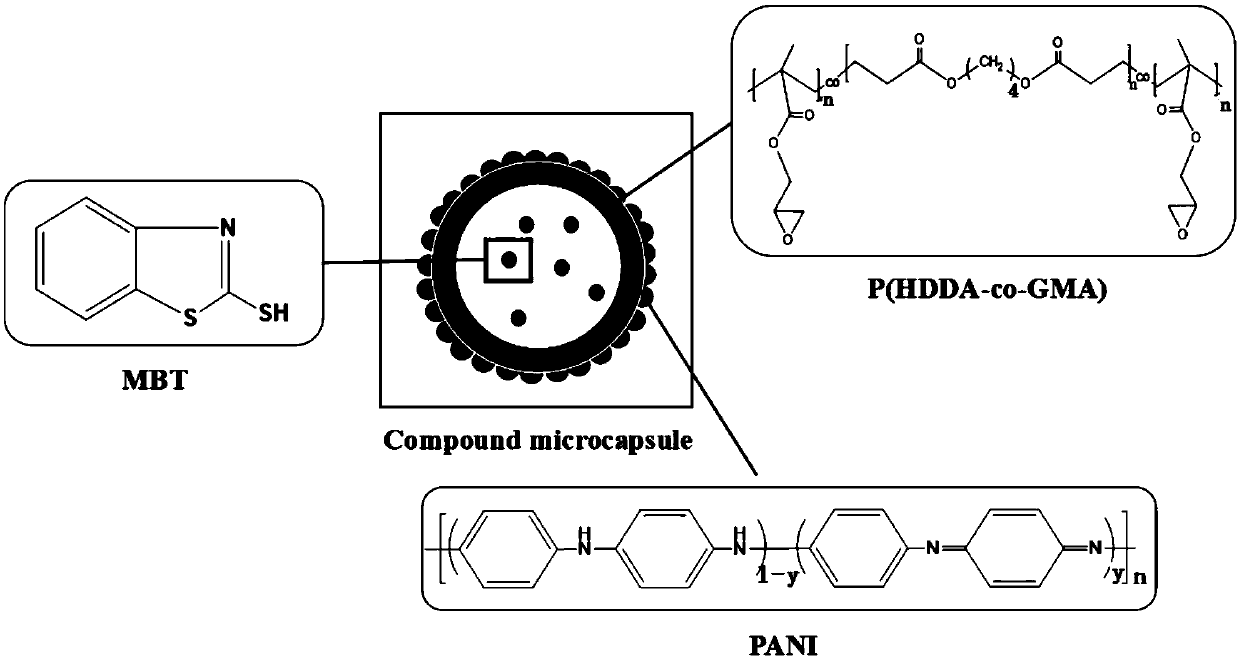

[0032] A method for preparing composite shell material microcapsules with dual anti-corrosion effects, comprising the steps of:

[0033] (1) First weigh 6g of nano-SiO 2 (50nm) dispersed in 50mL solvent ethanol, then add 120mg of diphenyldimethoxysilane, add ammonia water to adjust the pH to 10, react at 50°C for 8h, wash with ethanol and water alternately after the reaction to obtain modified nano-SiO 2 ;

[0034] (2) 180 mg of modified SiO obtained in step (1) was ultrasonically 2 Disperse evenly in 6mL ultrapure water as the water phase, and dissolve 0.3mL aniline, 0.9mL glycidyl methacrylate (GMA), 0.9mL 1,6-hexanediol acrylate (HDDA) in 3.9mL oil phase toluene In, add 36mg photoinitiator 369 simultaneously as oil phase; Mix oil-water two-phase, emulsify 2min by the emulsifying machine of 8000rmp to form stable oil-in-water (O / W) type emulsion;

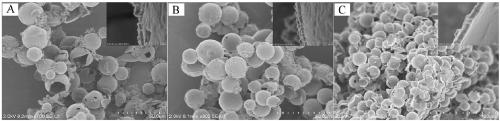

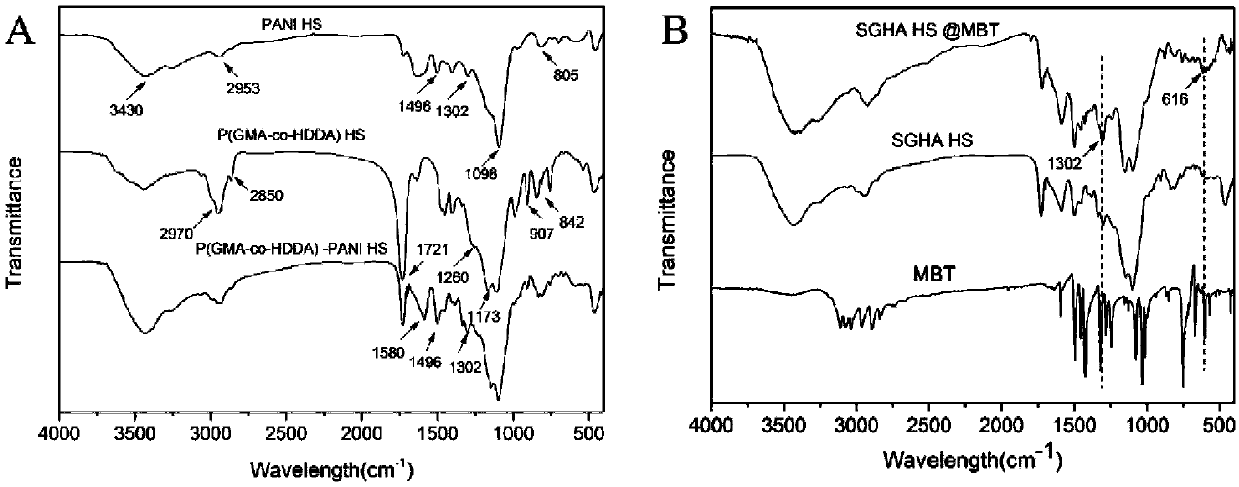

[0035](3) Place the emulsion prepared in step (2) in a UV curing machine for 3 minutes of light to polymerize the vinyl monom...

Embodiment 2

[0041] A method for preparing composite shell material microcapsules with dual anti-corrosion effects, comprising the steps of:

[0042] (1) First weigh 6g of nano-SiO 2 (100nm) dispersed in 50mL solvent ethanol, then add 300mg of 3-methoxyacryloxypropyltrimethoxysilane, add ammonia water to adjust the pH to 8, react at 60°C for 12h, wash with ethanol and water alternately after reaction get the product.

[0043] (2) The modified nano-SiO obtained in the step (1) of 240 mg is ultrasonically 2 Disperse evenly in 6mL ultrapure water, and dissolve 0.3mL aniline, 0.75mL dimethylaminoethyl methacrylate (DMAEMA), and 0.75mL divinylbenzene (DVB) in 1.2mL oil phase ethyl acetate at the same time 54mg of photoinitiator 1173 was added. Mix the two phases of oil and water, and emulsify for 5 minutes through an emulsifier at 10000rmp to form a stable oil-in-water (O / W) emulsion.

[0044] (3) Put the emulsion prepared in step (2) in a UV curing machine for 4 minutes to irradiate to pol...

Embodiment 3

[0047] A method for preparing composite shell material microcapsules with dual anti-corrosion effects, comprising the steps of:

[0048] (1) 300 mg of commercially available gas-phase SiO was ultrasonically 2 (15nm) was uniformly dispersed in 6mL ultrapure water, and at the same time, 0.3mL aniline, 0.72mL styrene (St), 0.18mL dipropylene glycol diacrylate (DPGDA) were dissolved in 0.3mL oil phase dichloroethane, and simultaneously added 41 mg Photoinitiator 907. Mix the two phases of oil and water, and emulsify them with an emulsifier at 12500rmp for 10min to form a stable oil-in-water (O / W) emulsion.

[0049] (2) Pour the emulsion prepared in step (1) into a UV curing machine for 5 minutes of light to polymerize vinyl monomers. After light, add 2 mL of aqueous solution containing 250 mg of ammonium persulfate and 50 μL of HCl (1M) drop by drop. , to polymerize aniline, react without any stirring at 20°C for 24h, alternately wash with water and ethanol and dry to obtain com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com