Difunctional fusion protein and method for producing D-phenyllactic acid from same

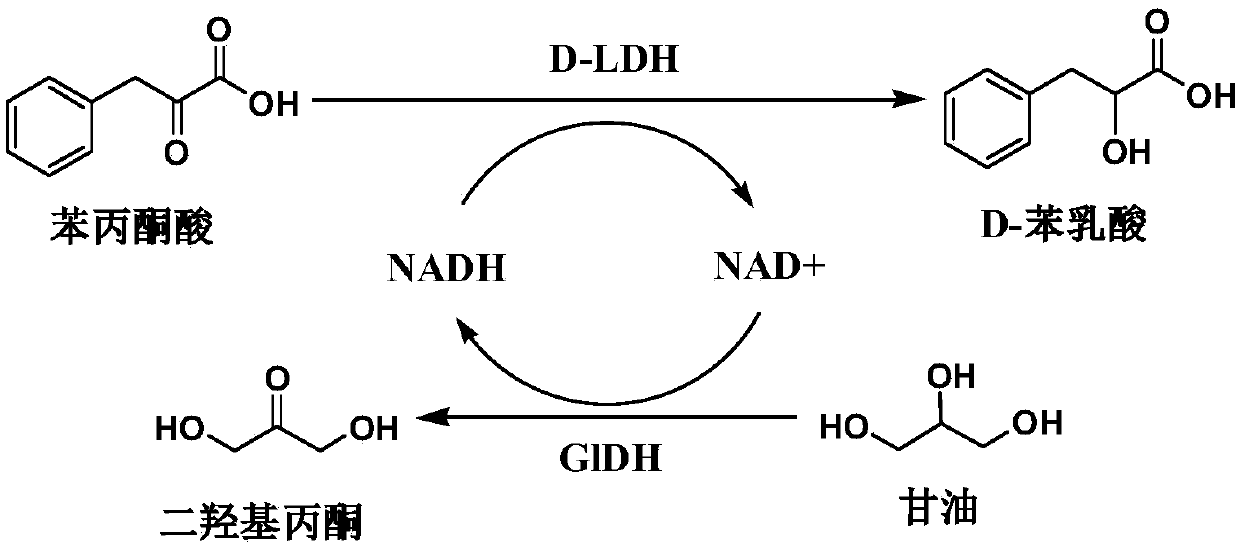

A fusion protein and fusion gene technology, which is applied in the field of engineering bacteria to catalyze the generation of D-phenyllactic acid, D-lactic dehydrogenase and glycerol dehydrogenase fusion proteins in whole cells, can solve the problems of hidden safety hazards and high investment costs, and achieve High safety, reduced production costs, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0085] The identification of embodiment 2 engineering bacterium expression product

[0086] (1) The engineering bacterium BL21 / pET28a-d-ldh-L obtained by implementing case 1 1 -gldh was inoculated into LB medium, cultured at 37°C to the logarithmic growth phase, added IPTG to a final concentration of 0.5mmol / L, and continued to culture for 12h. The bacteria were collected by centrifugation, ultrasonically disrupted, and the supernatant was collected by centrifugation. The purified fusion protein was purified by His-Tag affinity chromatography column, and verified by SDS-PAGE electrophoresis. A clear band was obtained at about 70KDa, which was consistent with the expected fusion protein. The size matches.

[0087] (2) Add the obtained purified protein solution into the reaction solution (2ml reaction system) to carry out the catalytic reaction. The reaction solution contains 10mM phenylpyruvate, 20mM glycerol, 1.8mL of 0.02mol / L potassium phosphate buffer solution, and reacted...

Embodiment example 3

[0088] Example 3 using BL21 / pET28a-d-ldh-L 1 -gldh whole-cell catalyzed production of D-phenyllactic acid

[0089] (1) Strains: BL21 / pET28a-d-ldh-L obtained in Example 1 1 -gldh.

[0090] (2) Insert the engineered bacteria into the seed culture medium, cultivate them in a shaker at 37°C and 200r / min for 10h, insert them into the fermentation medium (containing 40μg / mL kanamycin) according to the inoculum size of 5%, adjust The pH is between 6.0 and 7.0, placed in a shaker at 37°C, 200r / min, and shaken at a constant temperature to cultivate the cell density to OD 600 1.0, add 0.5mmol / L IPTG, and ferment at 25°C for 12h.

[0091] (3) Centrifuge at 4°C and 6000r / min for 10min, collect the bacteria, wash twice with 0.02M potassium phosphate buffer solution with pH 7.0, resuspend in 10ml containing 5% glycerol, 10g / L phenylpyruvate and 0.6% Tween 80 In the potassium phosphate buffer (pH 7.0, 0.02M) transformation system, the bacterial cell concentration OD 600 After reaching 5...

Embodiment 4

[0094] Example 4 utilizes BL21 / pET28a-d-ldh-L 2 -gldh(L 2 Representative linker: GGGGSGGGGS) Whole-cell catalytic production of D-phenyllactic acid

[0095] (1) bacterial classification: the primer P in embodiment 1 2R-1 ,P 3F-1 replace with P 2R-2 ,P 3F-2 , then the bacterial strain BL21 / pET28a-d-ldh-L obtained by the method of Example 1 2 -gldh, all the other construction methods are the same as embodiment 1;

[0096] P 2R-2 (5'-3'): TGATTGAATAATGCGGTCCATGGAGCCACCACCACCGGAGCCACCACCGCCACCAACCTTA ACTGG (SEQ ID NO.11)

[0097] P 3F-2 (5'-3'):GAAACCCCAGTTAAGGTTGGT GGCGGTGGTGGCTCCGGTGGTGGTGGCTCC ATGGACCGCATTATTCAATCACCG (GGGGSGGGGS) (SEQ ID NO. 12)

[0098] (2) Insert the engineered bacteria into the seed culture medium, cultivate them in a shaker at 30°C and 300r / min for 12h, insert them into the fermentation medium (containing 40μg / mL kanamycin) according to the inoculum size of 10%, adjust The pH is between 6.0 and 7.0, placed in a shaker at 37°C, 200r / min, and sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com