A kind of manufacturing method of lead-free tg140 copper clad laminate

A technology of TG140 and production method, which is applied in the production field of lead-free TG140 copper-clad laminates, can solve the problems of white spots on thick copper foil plates, low glass transition point temperature, and rising production costs, and achieve the improvement of glass transition point temperature and Heat resistance, low cost, effect of improving heat resistance and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

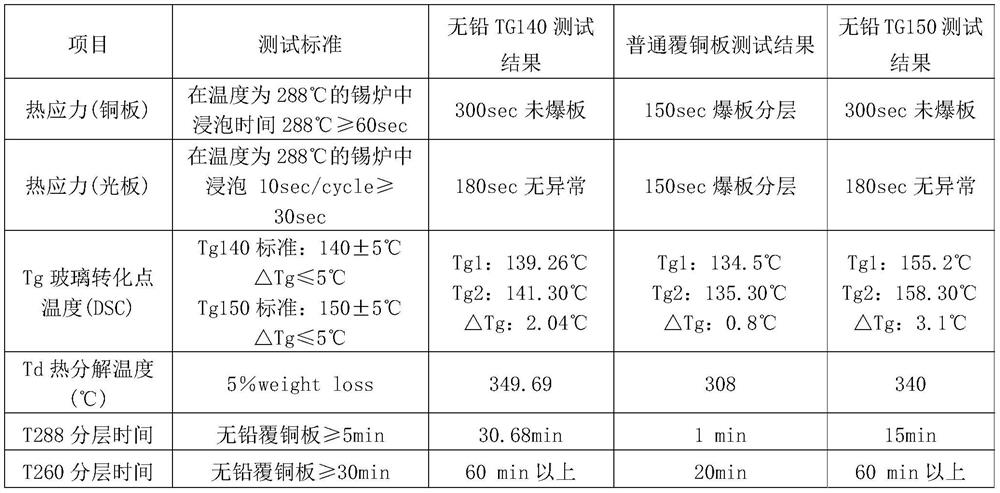

Image

Examples

Embodiment 1

[0045] A kind of manufacture method of lead-free TG140 copper-clad laminate of the present invention, the method comprises the following steps:

[0046] (1) the coupling agent of 2 weight parts, the low bromine bisphenol A type epoxy resin of 300 weight parts, the isocyanate modified epoxy resin of 100 weight parts, the high bromine epoxy resin of 5 weight parts, 10 weight parts The four-functional epoxy resin and 100 parts by weight of phenol-type novolac resin are added to the dissolution tank, and the cooling circulating water is started to ensure the temperature of the dissolution tank at 30±5°C, and then keep stirring at a speed of 650-750r / min for 1 hour to Completely even and set aside.

[0047] (2) Add 100 parts by weight of acetone, 100 parts by weight of propylene glycol methyl ether, and 10 parts by weight of cyclohexanone to the dissolving tank, continue to maintain the temperature of the dissolving tank after the addition is completed, and continue stirring for 1 ...

Embodiment 2

[0059] A kind of manufacture method of lead-free TG140 copper-clad laminate of the present invention, the method comprises the following steps:

[0060] (1) the coupling agent of 2.486 parts by weight, the low bromine bisphenol A type epoxy resin of 446.02 parts by weight, the isocyanate modified epoxy resin of 198 parts by weight, the high brominated epoxy resin of 9.823 parts by weight, 21.27 parts by weight The four-functional epoxy resin and 207.9 parts by weight of phenol-type novolac resin were added to the dissolution tank, and the cooling circulating water was started to keep the temperature of the dissolution tank at 30±5°C, and then kept stirring at a speed of 700r / min for 1 hour until completely uniform ,spare. Specifically, the novolak resin is or bisphenol A novolak resin.

[0061] (2) The acetone of 117.68 parts by weight, the propylene glycol methyl ether of 162 parts by weight, the cyclohexanone of 32.34 parts by weight are added to the dissolving tank, contin...

Embodiment 3

[0073] A kind of manufacture method of lead-free TG140 copper-clad laminate of the present invention, the method comprises the following steps:

[0074] (1) the coupling agent of 5 parts by weight, the low bromine bisphenol A type epoxy resin of 500 parts by weight, the bisphenol A type epoxy resin of the epoxy value of 300 parts by weight of 0.44, the high bromine of 15 parts by weight Epoxy resin, 30 parts by weight of four-functional epoxy resin and 300 parts by weight of bisphenol A novolac resin are added to the dissolution tank, start the cooling water circulation to ensure the temperature of the dissolution tank at 30 ± 5 ° C, and then maintain the speed Stir at 750r / min for 1 hour until completely uniform, set aside.

[0075](2) the methyl ethyl ketone of 200 weight parts, the propylene glycol methyl ether of 200 weight parts, the cyclohexanone of 50 weight parts are added dissolving tank, continue to keep the temperature of dissolving tank after adding, continue to st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com