A kind of method for preparing raspberry ketone under supercritical condition

A raspberry ketone, supercritical technology, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problems of easily polluted environment, high pressure on environmental protection, complicated post-processing, etc., and achieve reaction selectivity Effects of high, increased reaction temperature and pressure, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

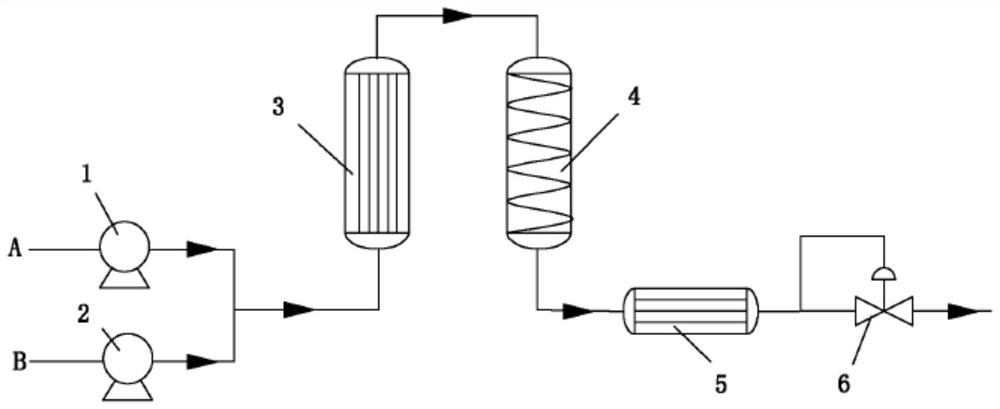

[0031] according to figure 1 As shown in the schematic diagram, turn on high-pressure metering pump 1, and pump acetone at a constant rate of 2g / min; toluene and p-Hydroxybenzaldehyde are prepared into a solution at a mass ratio of 3:1, turn on high-pressure metering pump 2, and pump at a constant rate of 4g / min Enter p-Hydroxybenzaldehyde toluene solution, preheater 3 temperature is set to 260 ℃, the temperature of supercritical pipeline reactor 4 is set to 300 ℃, adjust the high-precision reverse pressure controller 6 behind the condenser 5, The pressure is controlled at 20±1MPa, and the reaction residence time is 35min. After the reaction was completed, the reaction solution was collected and separated by rectification to obtain p-hydroxyphenylbutenone, and the calculated relative yield of p-hydroxybenzaldehyde was 96.1%.

Embodiment 2~5

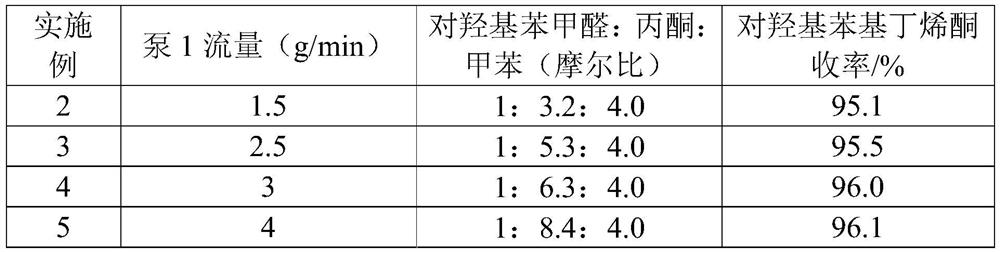

[0033] According to embodiment 1, by changing the flow rate of pump 1, to change the molar ratio of p-hydroxybenzaldehyde, acetone and toluene, keep the conditions such as the flow rate of pump 2, reaction temperature, preheater temperature, reaction pressure constant, after reaction finishes The results obtained are as follows (Table 1):

[0034] The influence of table 1 raw material ratio on reaction

[0035]

Embodiment 6~9

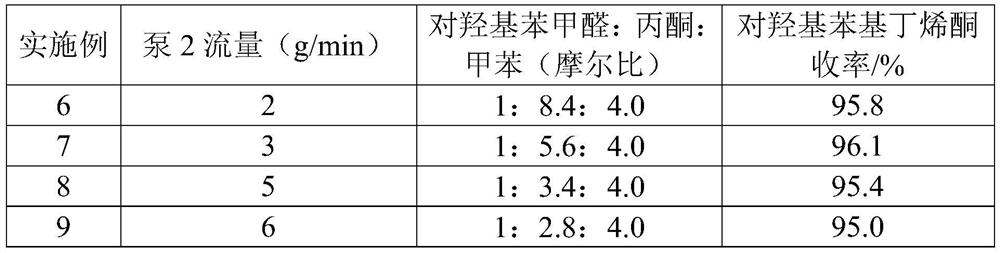

[0037] According to embodiment 1, by changing the flow rate of pump 2, to change the molar ratio of p-hydroxybenzaldehyde, acetone and toluene, keep conditions such as pump 1 flow rate, reaction temperature, preheater temperature, reaction pressure constant, after the reaction finishes, obtain The results are as follows (Table 2):

[0038] The influence of table 2 raw material ratio on reaction

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com