A kind of preparation method of nickel molybdate doped carbon quantum dot lithium ion battery negative electrode material

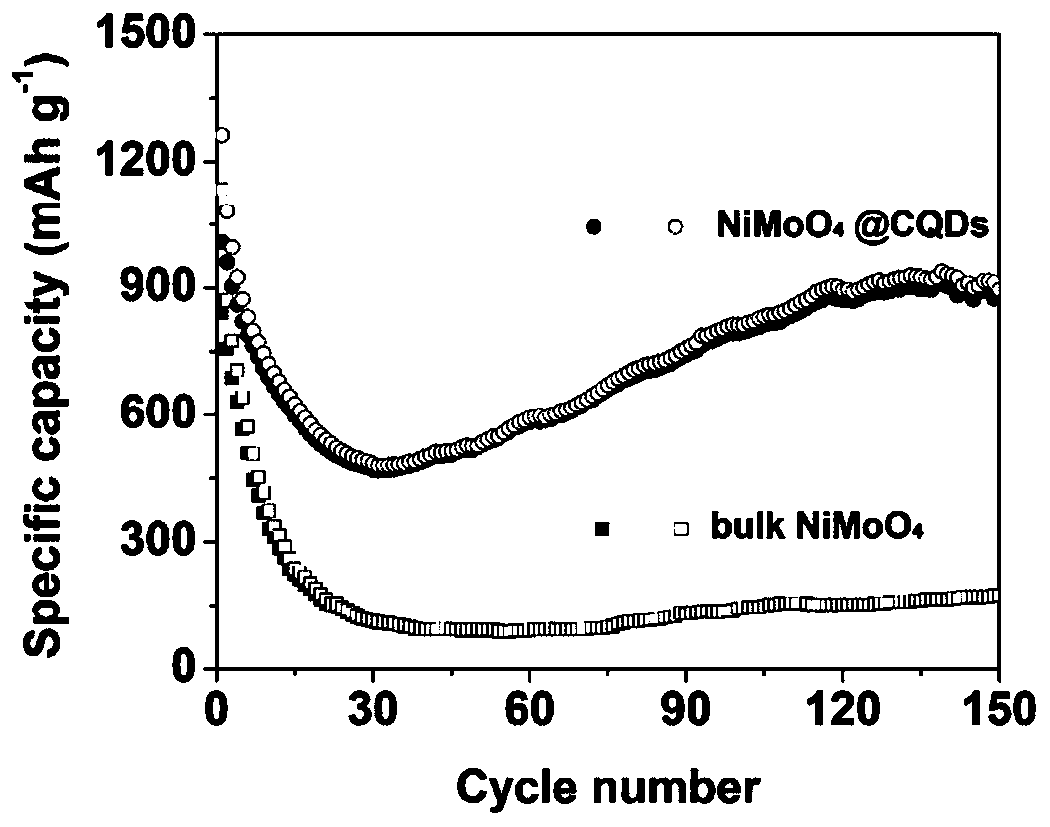

A lithium-ion battery, carbon quantum dot technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low conductivity and capacity fading, and achieve improved specific capacity and rate performance, high yield, and ease of volume. inflated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Add 200mg of citric acid to 30ml of hydrogen peroxide, stir at 80°C for 12 hours, then centrifuge at 8000rmp / min for 30min, take the supernatant for dialysis (molecular cut-off: 3500) and freeze-dry to obtain a brown powder;

[0022] 2) Take 0.1g carbon quantum dots, 2.62g nickel chloride hexahydrate (NiCl 2 ·6H 2 (2) and 2g ammonium molybdate are thoroughly mixed and ground in a mortar for 30min;

[0023] 3) Put the ground mixture into a muffle furnace from room temperature to 560°C at a heating rate of 10°C / min and keep it warm for 2 hours, then cool naturally;

[0024] 4) The above products were collected, washed three times with deionized water and absolute ethanol respectively, and then vacuum-dried for 36 hours to obtain nickel molybdate-doped carbon quantum dot lithium-ion battery negative electrode materials.

Embodiment 2

[0026] 1) Add 200mg of citric acid to 30ml of hydrogen peroxide, stir at 80°C for 12 hours, then centrifuge at 8000rmp / min for 30min, take the supernatant for dialysis (molecular cut-off: 3500) and freeze-dry to obtain a brown powder;

[0027] 2) Take 0.4g carbon quantum dots, 2.35g nickel chloride hexahydrate (NiCl 2 ·6H 2 (2) and 1.8g ammonium molybdate are thoroughly mixed and ground in a mortar for 10min;

[0028] 3) Put the ground mixture into a muffle furnace from room temperature to 300°C at a heating rate of 10°C / min and keep it warm for 4 hours, then cool naturally;

[0029] 4) The above products were collected, rinsed with deionized water and absolute ethanol for 5 times, and then vacuum-dried for 24 hours to obtain nickel molybdate-doped carbon quantum dot lithium-ion battery negative electrode materials.

Embodiment 3

[0031] 1) Add 200mg of citric acid to 30ml of hydrogen peroxide, stir at 80°C for 12 hours, then centrifuge at 8000rmp / min for 30min, take the supernatant for dialysis (molecular cut-off: 3500) and freeze-dry to obtain a brown powder;

[0032] 2) Take 0.6g carbon quantum dots, 2g nickel chloride hexahydrate (NiCl 2 ·6H 2 (2) and 1.53g ammonium molybdate are thoroughly mixed and ground in a mortar for 20min;

[0033] 3) Put the ground mixture into a muffle furnace and raise the temperature from room temperature to 400°C for 2.5 hours at a rate of 10°C / min, then cool naturally;

[0034] 4) The above products were collected, rinsed with deionized water and absolute ethanol for 4 times, and then vacuum-dried for 12 hours to obtain nickel molybdate-doped carbon quantum dot lithium-ion battery negative electrode materials.

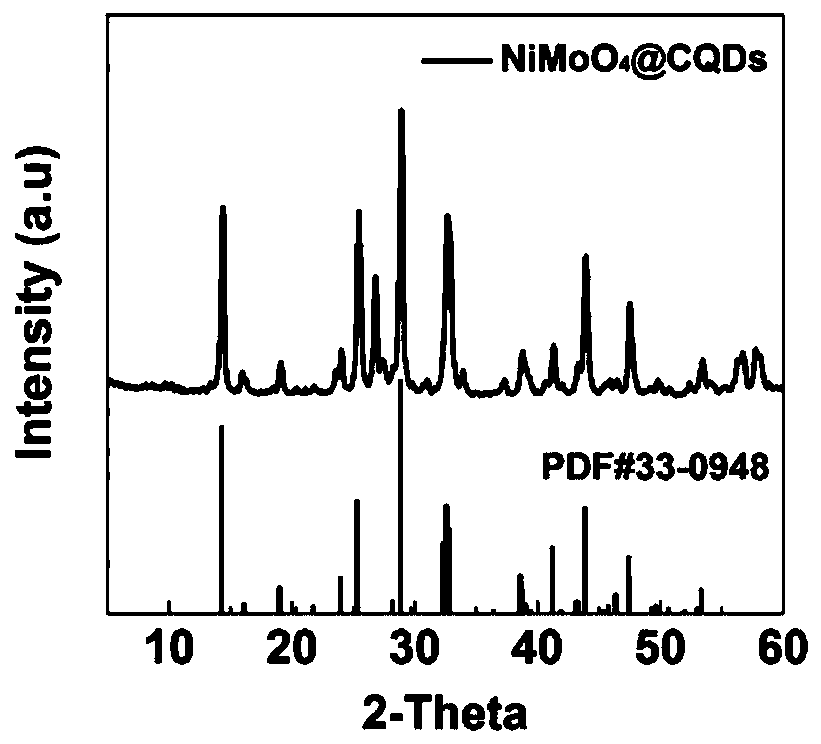

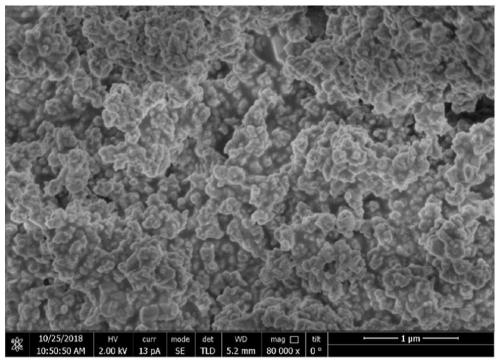

[0035] Depend on figure 1 It can be seen that the prepared product is NiMoO 4 , compared with the standard PDF card (No.21-0569), it can be seen that the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com