Iron-based oil-containing bearing material of controllable pore structure and preparation method of iron-based oil-containing bearing material

A bearing material and pore structure technology, which is applied in the field of bearing materials, can solve the problems of lack of communication with the outside world, the decline of the oil storage capacity of the material, the influence of the iron matrix, etc., so as to improve the mechanical properties, enhance the oil storage performance, and improve the connectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The operation steps of preparing the iron-based oil bearing material with controllable pore structure are as follows:

[0031] Step 1. According to the mass percentage, weigh 116.58g (97.15%) of iron powder, titanium hydride powder (TiH 2 ) 2.4g (2%), graphite powder 0.78g (0.65%), hair strands 0.24g (0.2%), a total of 120g; plus zinc stearate 0.6g (0.5% of the total mass).

[0032] Step 2. Add the above mixed powder into the grinding tank for ball milling. In the tank, there are 250g of large balls and 350g of small balls. Vacuumize, fill with high-purity argon, rotate at a speed of 300r / min, mill for 10 hours, and stop for 15 minutes every 60 minutes of ball milling to facilitate heat dissipation during ball milling. , after the ball milling, it was naturally cooled for 5 hours, and a uniformly mixed powder was obtained.

[0033] Step 3. Put the above-mentioned powder into a pressing mold, and make a green body under unidirectional pressure. The pressure for pressing...

Embodiment 2

[0038] The operation steps for preparing the iron-based oil-impregnated bearing material are as follows:

[0039] 1. According to the mass percentage, weigh 116.58g (97.15%) of iron powder, titanium hydride powder (TiH 2 ) 2.4g (2%), graphite powder 0.78g (0.65%), hair strands 0.24g (0.2%), a total of 120g; plus zinc stearate 0.6g (0.5% of the total mass);

[0040] 2. Same as Step 2 of Example 1;

[0041] 3. Same as Step 3 of Example 1;

[0042] 4. Same as Step 4 of Example 1;

[0043] 5. Put the sintered material into the ordinary oil and vacuum immerse it in oil. The amount of oil is more than the amount of immersion sample, the oil immersion time is 3 hours, the vacuum pressure value is not more than 7KPa, and the oil temperature is 70℃~100℃;

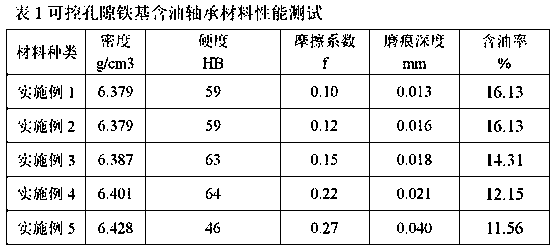

[0044] 6. The test samples were tested for mechanical properties and friction and wear performance under dry friction conditions. The prepared oil-containing iron base has a hardness of 59HRB, an oil content of 16.13%, and a den...

Embodiment 3

[0046] The operation steps for preparing the iron-based oil-impregnated bearing material are as follows:

[0047] 1. According to the mass percentage, weigh 116.58g (97.15%) of iron powder, titanium hydride powder (TiH 2 ) 2.4g (2%), graphite powder 0.78g (0.65%), hair strands 0.24g (0.2%), a total of 120g; plus zinc stearate 0.6g (0.5% of the total mass)

[0048] 2. Put the above powder into the pressing mold, and make a green body under unidirectional pressure. The pressure of pressing the green body is 650~750MPa.

[0049] 3. Put the pressed billet into the mesh belt sintering furnace, pass through the decomposed ammonia gas for protection, the sintering temperature is 1050~1200 ℃, and the holding time is 4 h.

[0050]4. Put the sintered material into the ordinary oil and vacuum immerse it in oil. The amount of oil is more than the amount of immersion sample, the oil immersion time is 3 hours, the vacuum pressure value is not more than 7KPa, and the oil temperature is 70℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com