Environment-friendly simulated floriculture material and method of manufacturing artware therefrom

A kind of artificial flower, environmental protection technology, applied in the field of artificial flower art, can solve the problems of aging resistance, poor flexibility, high strength, hardness, complex production process, etc., to achieve high nylon resilience, improved surface activity, good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

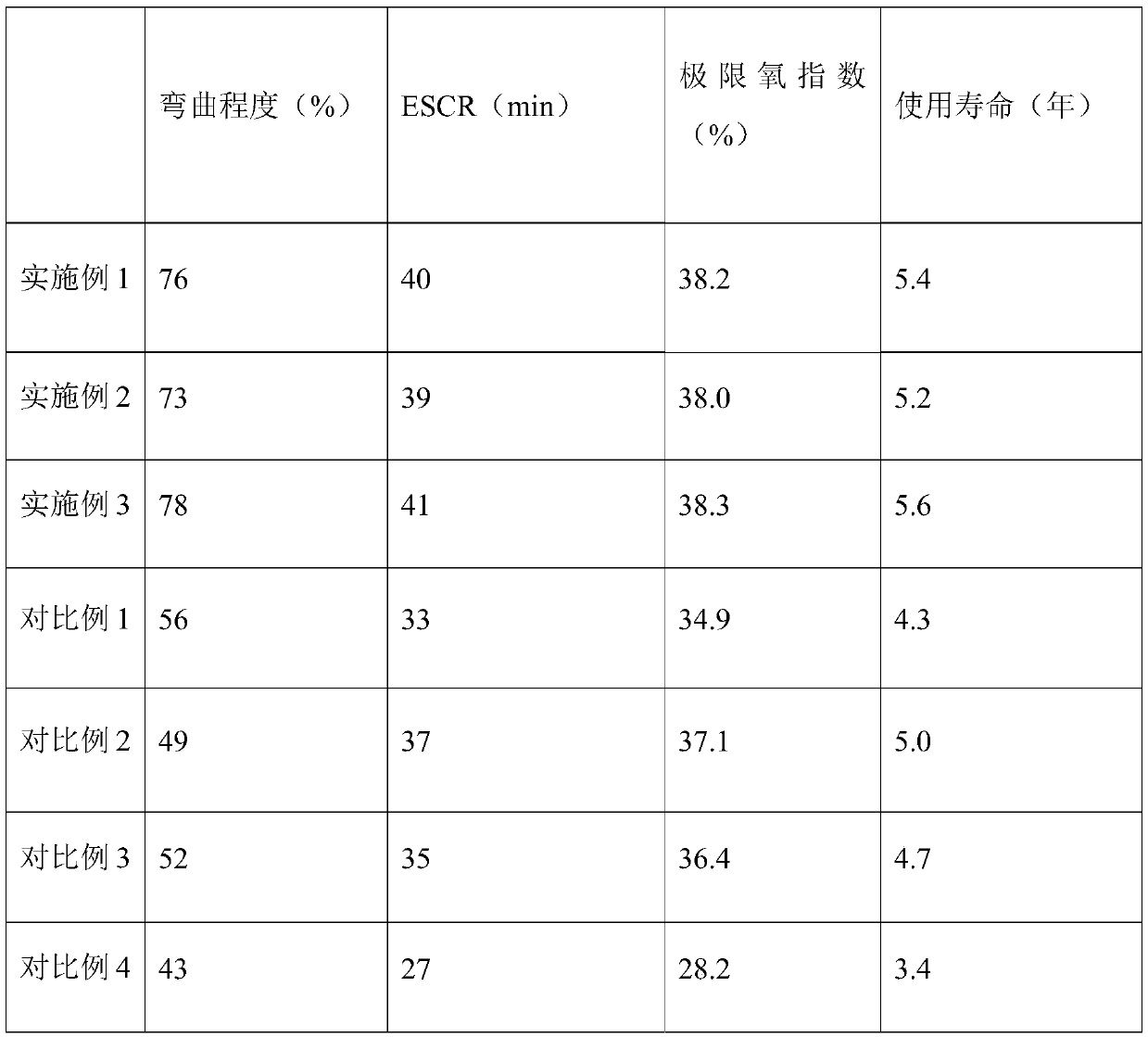

Examples

Embodiment 1

[0030] A kind of environment-friendly artificial flower art material of the present embodiment comprises the raw material of following weight part:

[0031] 50 parts of PVC, 10 parts of modified PP, 10 parts of nylon, 8 parts of lignocellulose, 5 parts of coupled helical carbon nanotubes, 6 parts of aluminum silicate modified aramid staple fiber, 2 parts of novolac resin, polyurethane 1 part of fat foaming agent, 1 part of coumarin, 10 parts of glycerin.

[0032] The preparation method of the modified PP in this example is as follows: feed PP resin and diatomaceous earth into a twin-screw extruder at a weight ratio of 1:0.1 for extrusion, then granulate, cool after granulation, and then place Soak in dilute sulfuric acid solution for 30 minutes, then take it out and soak in alginic acid with a concentration of 0.1mol / L for 20 minutes, then wash with water until the washing liquid is neutral, then mix with lignin at a weight ratio of 1:3, and then perform steam explosion For p...

Embodiment 2

[0042] A kind of environment-friendly artificial flower art material of the present embodiment comprises the raw material of following weight portion:

[0043] 70 parts of PVC, 20 parts of modified PP, 20 parts of nylon, 14 parts of lignocellulose, 10 parts of coupled spiral carbon nanotubes, 11 parts of aluminum silicate modified aramid staple fiber, 5 parts of novolac resin, polyurethane 3 parts of fat foaming agent, 2 parts of coumarin gum, 20 parts of glycerin.

[0044] The preparation method of the modified PP in this example is as follows: feed PP resin and diatomaceous earth into a twin-screw extruder at a weight ratio of 1:0.2 for extrusion, then granulate, cool after granulation, and then place Soak in dilute sulfuric acid solution for 40 minutes, then take it out and soak in alginic acid with a concentration of 0.6mol / L for 30 minutes, then wash with water until the washing liquid is neutral, then mix with lignin at a weight ratio of 1:3, and then perform steam explo...

Embodiment 3

[0054] A kind of environment-friendly artificial flower art material of the present embodiment comprises the raw material of following weight part:

[0055] 60 parts of PVC, 15 parts of modified PP, 15 parts of nylon, 11 parts of lignocellulose, 7.5 parts of coupled helical carbon nanotubes, 8.5 parts of aluminum silicate modified aramid staple fiber, 3.5 parts of novolac resin, polyurethane 2 parts of fat foaming agent, 1.5 parts of coumarin, 15 parts of glycerol.

[0056] The preparation method of the modified PP in this example is as follows: feed PP resin and diatomaceous earth into a twin-screw extruder at a weight ratio of 1:0.15 for extrusion, then granulate, cool after granulation, and then place Soak in dilute sulfuric acid solution for 35 minutes, then take it out and soak in alginic acid with a concentration of 0.35mol / L for 25 minutes, then wash with water until the washing liquid is neutral, then mix with lignin at a weight ratio of 1:3, and then perform steam exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com