Bismuth-tungstate-modified antimony-doped stannic oxide compound photoelectrocatalysis electrode, preparing method and application

A technology of tin dioxide and photoelectric catalysis, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of low photocatalytic efficiency and achieve electrocatalytic performance Improvement, improvement of processing efficiency, effect of photocurrent increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

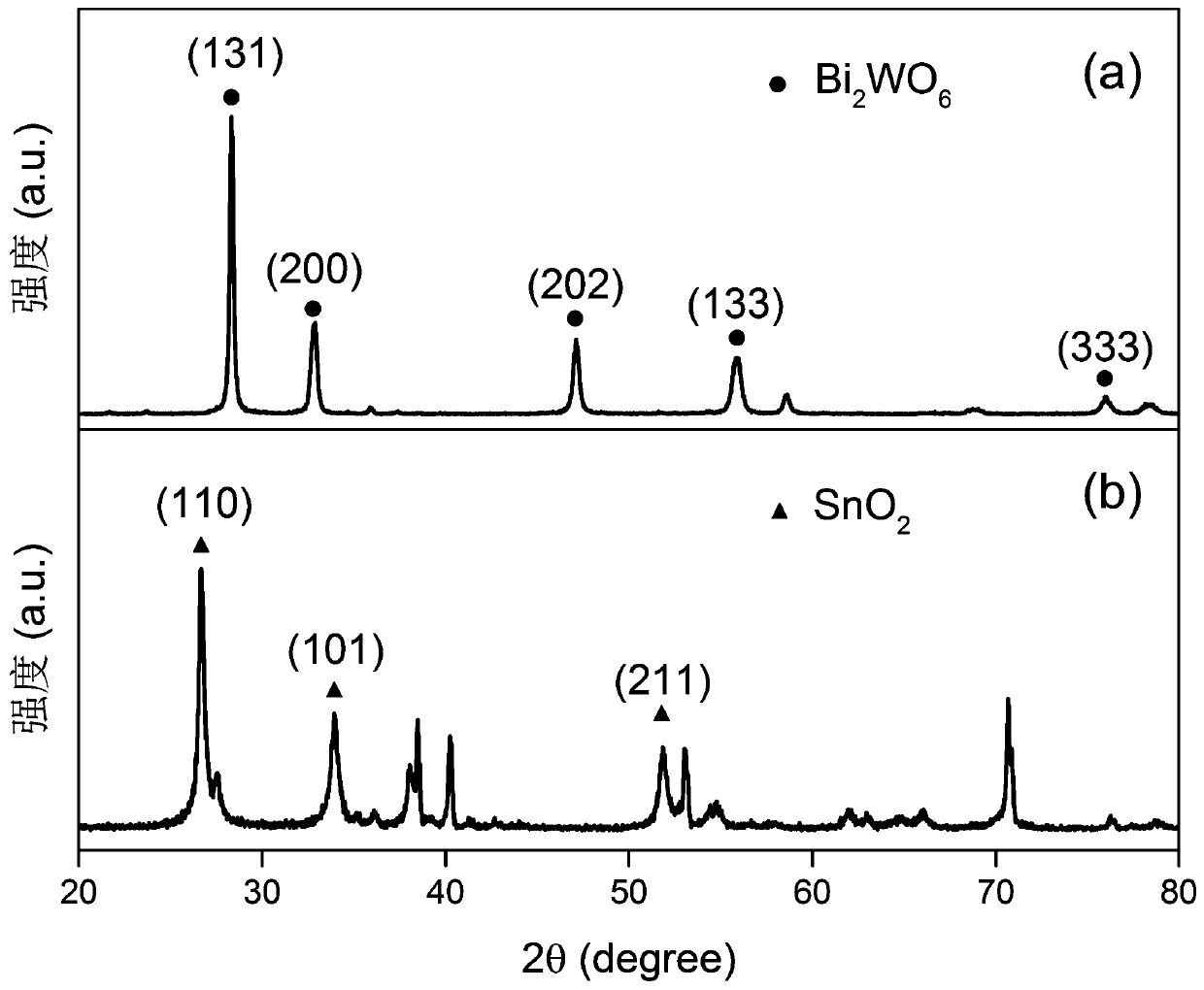

[0041] In this example, the preparation method of bismuth tungstate modified antimony-doped tin dioxide composite photoelectrocatalytic electrode is as follows:

[0042] S1. Dissolve 2 mmol of bismuth nitrate pentahydrate in 30 mL of water, stir and sonicate for 30 min to obtain solution A;

[0043] Dissolve 1mmol sodium tungstate dihydrate in 20mL ethylene glycol, stir and sonicate for 30min to obtain solution B;

[0044] Solution B was dripped into solution A at a rate of 0.3mL / min under ultrasonic conditions and mixed to obtain solution C;

[0045] Transfer solution C to a hydrothermal reaction kettle, react at 180°C for 12h, take it out and cool to room temperature, filter the obtained product with suction, wash with water and ethanol three times, and then dry at 80°C for 12h to obtain bismuth tungstate (in Bi 2 WO 6 meter), the product was placed in a crucible, and calcined at 450°C for 3h;

[0046] S2, citric acid, ethylene glycol, tin tetrachloride pentahydrate, ant...

Embodiment 2

[0053] In order to test the bismuth tungstate prepared in Example 1 to modify the antimony-doped tin dioxide composite photoelectrocatalytic electrode to the degradation effect of ciprofloxacin, adopt the following method to test:

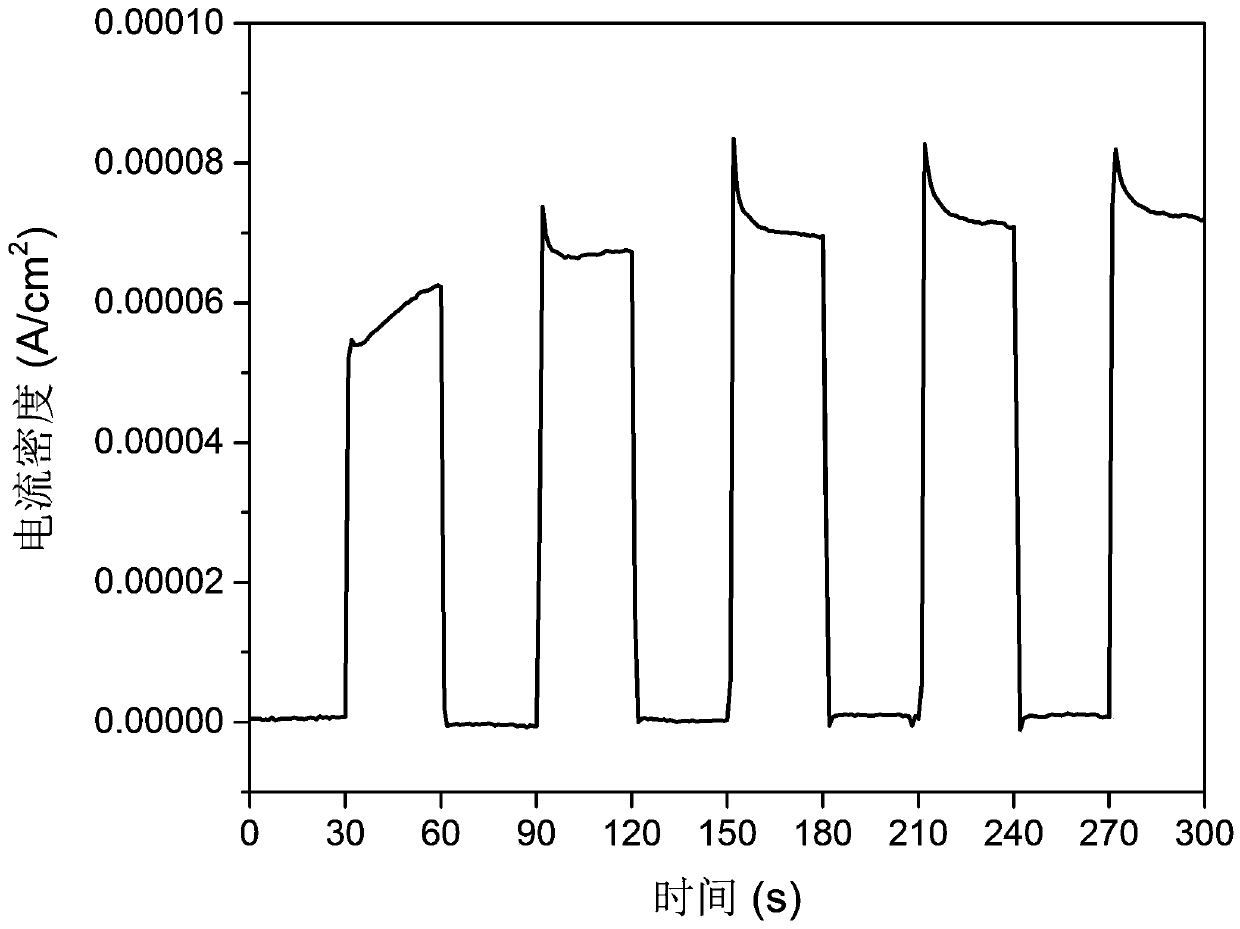

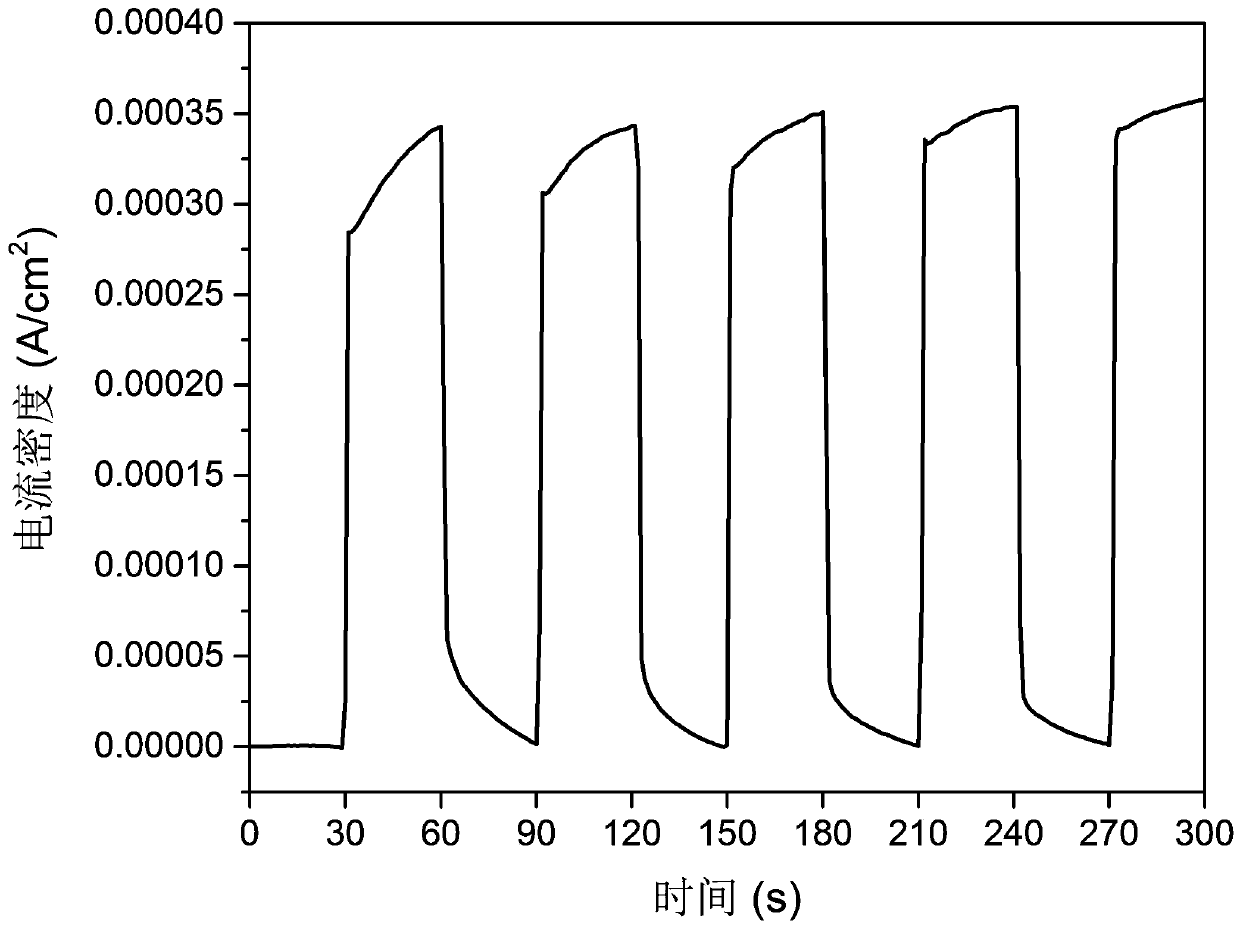

[0054] Preparation concentration is 100mL of ciprofloxacin simulated waste water of 30mg / L, add 25g / L sodium sulfate as electrolyte, the electrode prepared in Example 1 is used as anode, stainless steel is used as cathode, and the control current density is 15mA / cm 2 . Stir in the dark for 30 minutes, turn on the light source and power on at the same time, take samples every 15 minutes, measure the concentration of ciprofloxacin, and record the data. Figure 4 It is the time-varying curve of the degradation of ciprofloxacin by the composite photoelectrocatalytic electrode of Example 1. The results show that after light irradiation for 60min, the electrode prepared in Example 1 can remove more than 90% of ciprofloxacin, while the unmodified antimon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com