Nitrogen-doped porous hollow carbon catalyst embedded in platinum-rhodium alloy, preparation method and application thereof

A technology of antimony alloy and nitrogen doping, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of short life, short service life, high cost of proton exchange membrane electrodes, etc., to achieve The effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

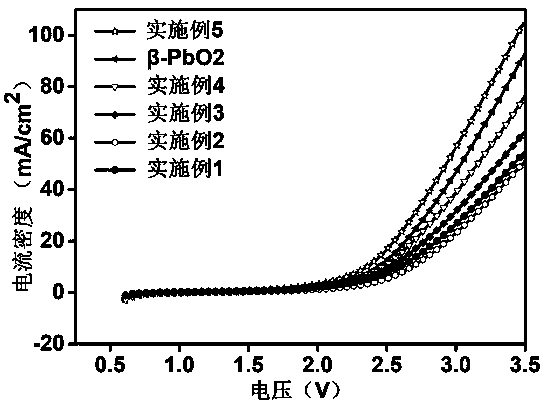

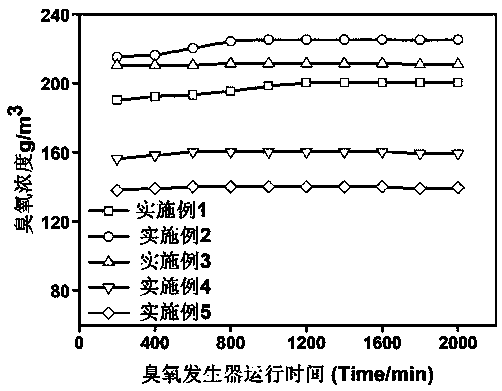

Examples

Embodiment 1

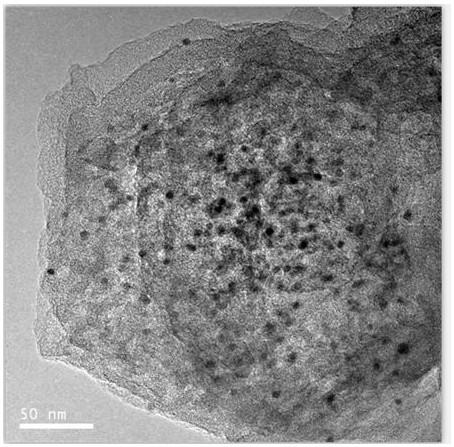

[0032] The preparation of a catalyst based on a 1-3 nm platinum-antimony alloy embedded in nitrogen-doped porous hollow carbon comprises the following steps:

[0033] 1) 0.023 g of chloroplatinic acid and 0.002 g of antimony chloride were dissolved in 20 mL of ethylene glycol and refluxed in an oil bath at 150 °C for 3 h under nitrogen bubbling. After cooling to room temperature, 2 mL of hydrochloric acid (1 mol / L ), and then centrifuged to obtain viscous matter dispersed in 20mL of water to obtain a suspension of platinum-antimony alloy nanoparticles (the concentration of the platinum-antimony alloy nanoparticles in the suspension is 1.3g / L).

[0034] 2) Add 20 mL of the aqueous suspension of platinum-antimony alloy nanoparticles obtained in step 1) into 60 mL of methanol solution containing 1 g of zinc chloride and 4 g of dimethylimidazole; stir vigorously for 1 h, and the resulting turbid solution is left to stand for 24 h. Place, filter, and vacuum-dry; obtain solid powder...

Embodiment 2

[0040] The preparation of a catalyst based on a 3-6 nm platinum-antimony alloy embedded nitrogen-doped porous hollow carbon comprises the following steps:

[0041] 1) Disperse 0.023 g of chloroplatinic acid, 0.002 g of antimony chloride, and 150 mg of PVP in 200 mL of ethanol and reflux in an oil bath at 80 °C for 2 h under nitrogen protection. The resulting mixture was removed by rotary evaporation After the solvent was removed, acetone was added to the residue of rotary evaporation to obtain a turbid mixed solution, and the viscous obtained by centrifugation was dispersed in 20 mL of water to obtain a suspension water of platinum-antimony alloy nanoparticles (the platinum-antimony alloy nanoparticles were in the suspension. The concentration is 1.3 g / L).

[0042] 2) Add 20 mL of the aqueous suspension of platinum-antimony alloy nanoparticles obtained in step 1) to 60 mL of methanol solution containing 1 g of zinc chloride and 4 g of dimethylimidazole; stir vigorously for 1 h...

Embodiment 3

[0048] The preparation of a catalyst based on a 4-7 nm platinum-antimony alloy embedded nitrogen-doped porous hollow carbon comprises the following steps:

[0049] 1) Disperse 0.023 g of chloroplatinic acid, 0.002 g of antimony nitrate and 150 mg of PVP in 200 mL of ethanol, under the condition of nitrogen protection, reflux for 2 h in an oil bath at 80 °C, and remove the solvent by rotary evaporation Finally, add acetone to the rotary steaming residue to obtain a turbid mixed solution, and disperse the viscous substance in 20mL water through centrifugation to obtain the suspension water of platinum-antimony alloy nanoparticles (the concentration of the platinum-antimony alloy nanoparticles in the suspension is is 1.3 g / L).

[0050] 2) Add 20 mL of the aqueous suspension of platinum-antimony alloy nanoparticles obtained in step 1) to 60 mL of methanol solution containing 1 g of zinc chloride and 4 g of dimethylimidazole; stir vigorously for 1 h, and the resulting cloudy soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com