A kind of preparation method of secondary modified light calcium carbonate for plastic products

A light calcium carbonate, secondary modification technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problem that the secondary modified light calcium carbonate is limited to laboratories, and there is no industrial mass production of products, etc. Achieve the effects of improving surface finish, increasing filling capacity and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

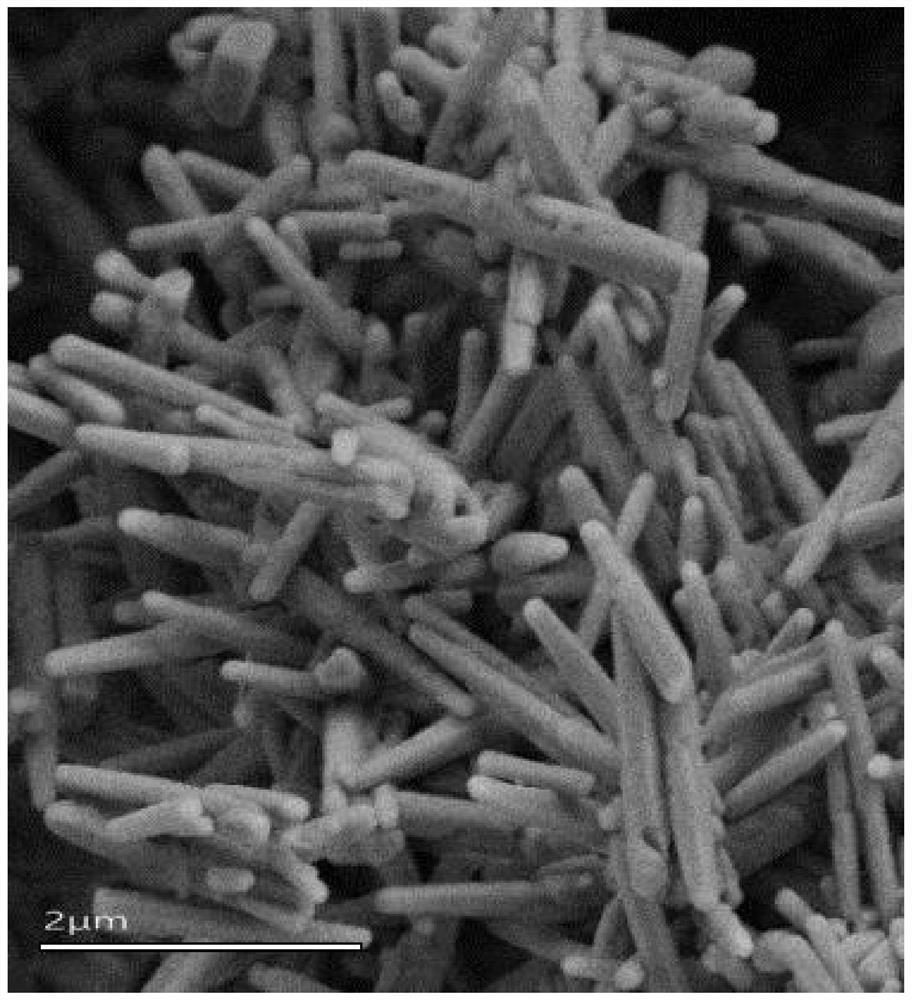

Image

Examples

Embodiment 1

[0036] A preparation method for secondary modified light calcium carbonate for plastic products, comprising the following steps,

[0037] Step 1: Hydrate calcium oxide with water at 60°C in a mass ratio of 1:5, remove impurities from the prepared calcium hydroxide emulsion through a vibrating screen and a suspension separator, and age for 48 hours for later use;

[0038] Step 2, adjusting the concentration of the aged calcium hydroxide seminal pulp to 1.3mol / L, adding a crystal form control agent of 0.3% by dry weight of calcium carbonate, and the crystal form control agent is perfluoroalkyl betaine and aluminum chloride , the mass ratio is 1:1, and the temperature is adjusted to 70°C;

[0039]Step 3. Transport the fine calcium hydroxide slurry in step 2 to the carbonization kettle, adjust the frequency of the stirring motor of the carbonization kettle to 50Hz, and feed in the purified, cooled and compressed lime kiln gas for carbonization reaction. The kiln gas flow rate is 1...

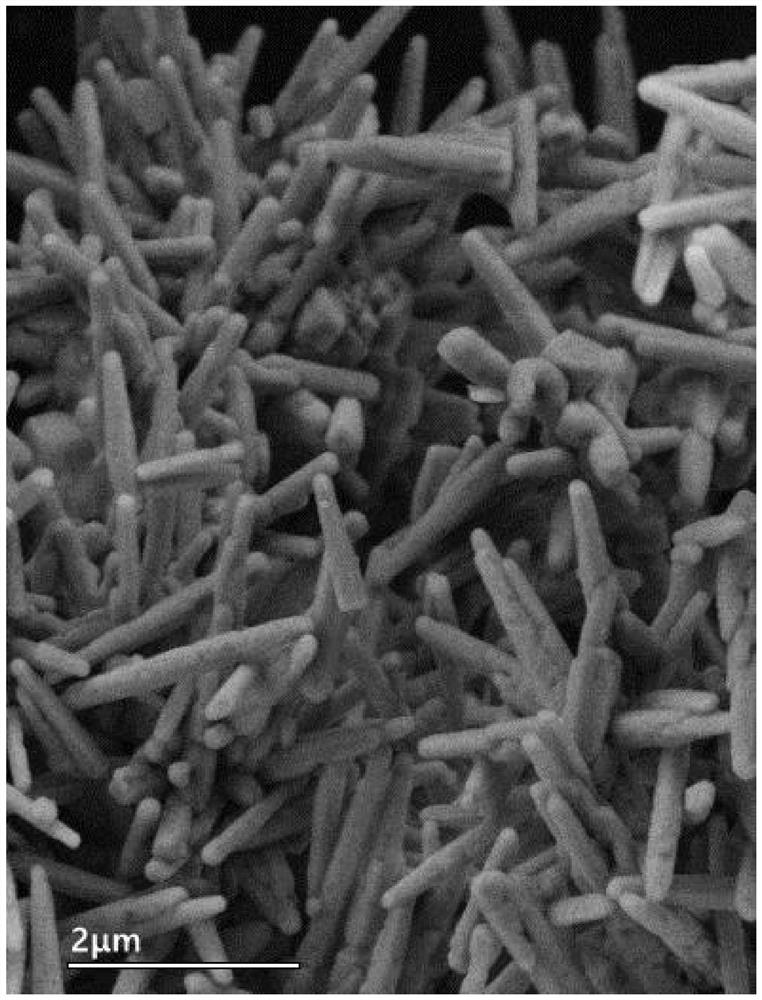

Embodiment 2

[0044] A preparation method for secondary modified light calcium carbonate for plastic products, comprising the following steps,

[0045] Step 1. Hydrate calcium oxide and water at 62°C in a mass ratio of 1:5, remove impurities from the prepared calcium hydroxide emulsion through a vibrating screen and a suspension separator, and age for 50 hours for later use;

[0046] Step 2, adjusting the concentration of the aged calcium hydroxide seminal pulp to 1.4mol / L, adding a crystal form control agent of 0.2% by dry weight of calcium carbonate, the crystal form control agent being perfluoroalkyl betaine and magnesium sulfate, Its mass ratio is 1:1, and the temperature is adjusted to 75°C;

[0047] Step 3: Transport the fine calcium hydroxide slurry in step 2 to the carbonization kettle, adjust the frequency of the stirring motor of the carbonization kettle to 50Hz, and feed in the purified, cooled and compressed lime kiln gas for carbonization reaction, and the flow rate of the kiln...

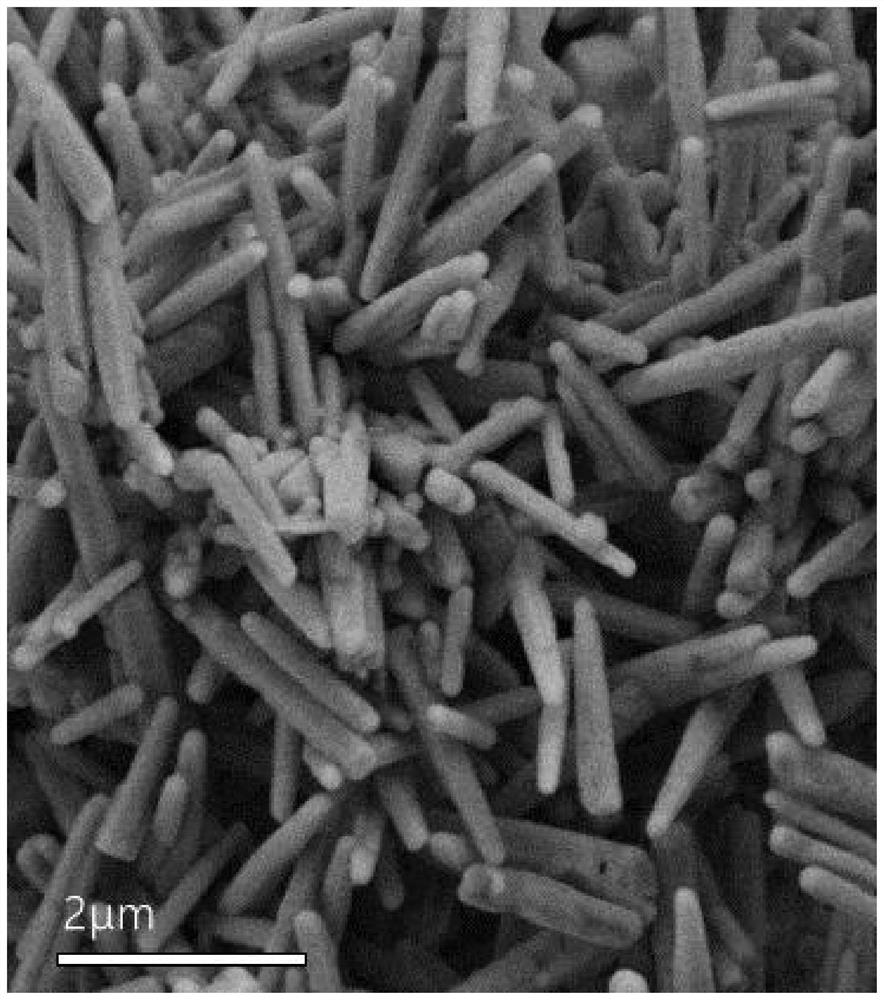

Embodiment 3

[0052] A preparation method for secondary modified light calcium carbonate for plastic products, comprising the following steps,

[0053] Step 1, hydration reaction of calcium oxide and water at 65°C in a mass ratio of 1:5, the prepared calcium hydroxide emulsion is removed by a vibrating screen and a suspension separator, and aged for 53 hours for later use;

[0054] Step 2, adjusting the concentration of the aged calcium hydroxide seminal pulp to 1.5mol / L, adding a crystal form control agent of 0.15% by dry weight of calcium carbonate, the crystal form control agent is perfluoroalkyl betaine, magnesium chloride, and The mass ratio is 1:1, and the temperature is adjusted to 78°C;

[0055] Step 3. Transport the fine calcium hydroxide slurry in step 2 to the carbonization kettle, adjust the frequency of the stirring motor of the carbonization kettle to 50Hz, and feed the purified, cooled, and compressed lime kiln gas for carbonization reaction. The kiln gas flow rate is 2.0m 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com