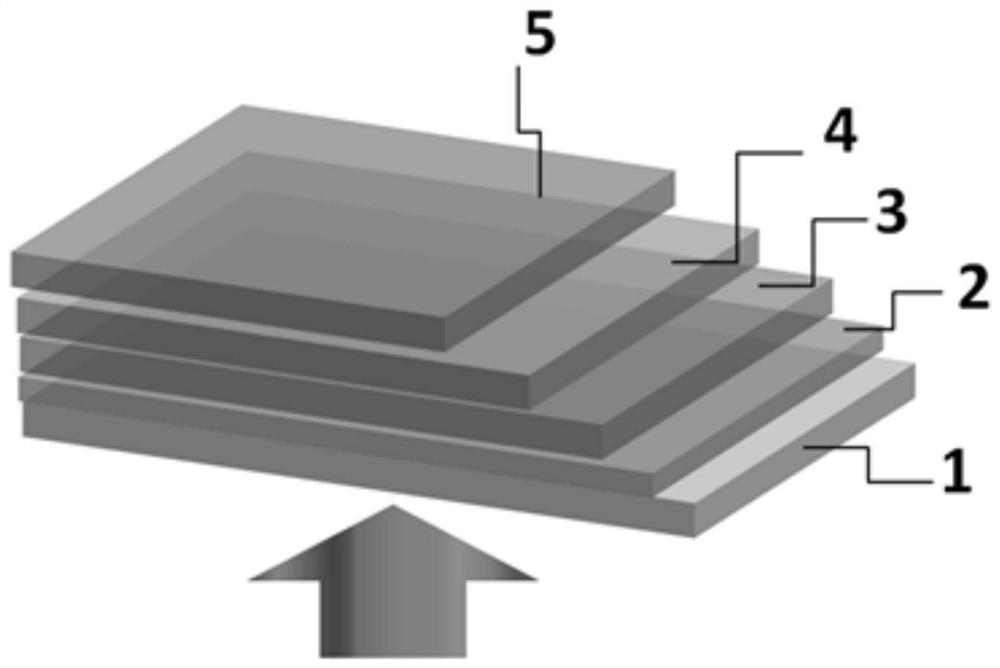

A kind of all-inorganic perovskite photodetector and its preparation method

A photodetector, inorganic calcium technology, used in circuits, electrical components, semiconductor devices, etc., can solve the problems of inability to obtain high crystalline quality films, thick charge transport layer film thickness, insufficient detection sensitivity limit, etc. Photoelectric responsivity, beneficial to absorption, and the effect of reducing the dark current of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) The commercial FTO was partially etched by the mixed reaction of dilute hydrochloric acid (HCl) and zinc powder (Zn), and then the substrate was ultrasonically cleaned in deionized water, acetone and isopropanol for 15 minutes each; The substrate was blown dry with nitrogen, and treated with ultraviolet ozone for 30 minutes.

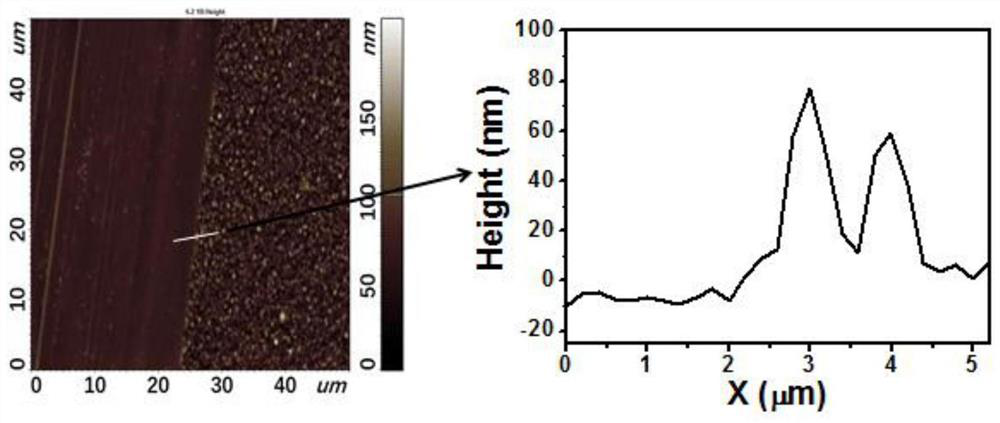

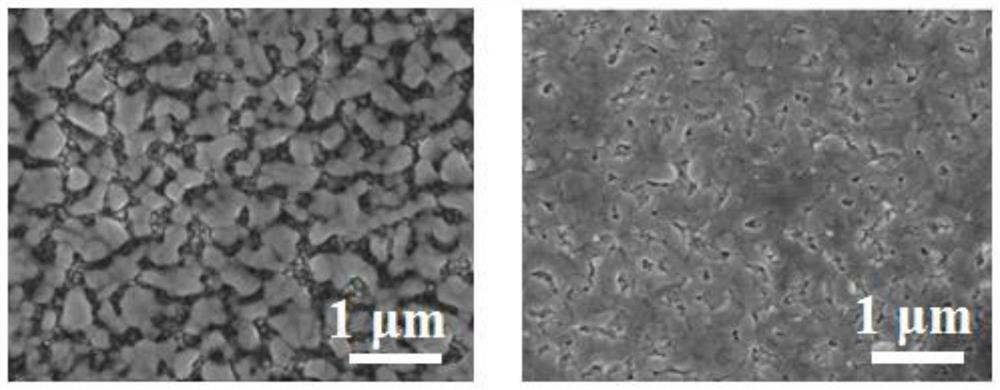

[0050] (2) Deposit a layer of aluminum oxide film with a thickness of 1.5nm on the substrate treated by (1) by ALD technology (model: BENEQ, TFS200), the precursor source is trimethylaluminum (TMA), and the deposition conditions are: The chamber temperature was 85° C., the chamber pressure was 9 Pa, and the growth cycle was 16 times.

[0051] (3) Dissolve 0.33mol cesium bromide and 0.33mol lead bromide in 1mL dimethyl sulfoxide solution, heat and stir at 70°C for 12h to obtain CsPbBr 3 Precursor solution: Spin-coat the precursor solution on the aluminum oxide film, the spin-coating conditions are: spin-coating at 500rpm for 6 seconds, and spi...

Embodiment 2

[0056] 1. With reference to Example 1, only the thickness of the aluminum oxide thin film layer in step (2) is made into 1nm by ALD technology, wherein the growth cycle is 11 times, and other process parameters are the same as in Example 1 to obtain an all-inorganic perovskite photoelectric detector. The device has low dark current and high stability.

[0057] 2. With reference to Example 1, only the thickness of the aluminum oxide film layer in step (2) is made into 3nm by ALD technology, wherein the growth cycle is 32 times, and other process parameters are the same as in Example 1 to obtain an all-inorganic perovskite photoelectric detector. The device has low dark current and high stability.

[0058] 3. With reference to Example 1, only the thickness of the titanium oxide film layer in step (4) is made into 5nm by ALD technology, wherein the growth cycle is 86 times, and other process parameters are the same as in Example 1 to obtain an all-inorganic perovskite photoelec...

Embodiment 3

[0061] With reference to Example 1, only the commercial FTO in step (1) is changed into PET / ITO, and other process parameter conditions are the same as in Example 1 to obtain an all-inorganic perovskite photodetector, and its current-time curve is as follows Figure 9 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com