Liquid fertilizer made from amino acid fermentation tail liquor

A technology of liquid fertilizer and fermentation tail liquid, which is applied in the direction of liquid fertilizer, fertilizer made from biological waste, ammonium orthophosphate fertilizer, etc. It can solve the problems of increasing the burden on enterprises, difficulty in obtaining cost-effective by-products, and difficulty in processing, so as to promote plant growth. The effect of growth and root development, eliminating the waste liquid treatment process, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The liquid fertilizer made from amino acid fermentation tail liquid is prepared according to the following process:

[0032] The amino acid fermentation tail liquid is separated by a disc separator with a rotating speed of 4000rpm and a centrifugation time of 5 minutes, collecting the bacterial sediment and waste mother liquor, drying the bacterial sediment, and then pulverizing it into bacterial powder by a pulverizer;

[0033] Aspergillus niger ATCC 16404 was inoculated into the medium of the seed tank for cultivation, the temperature was controlled at 30°C, and the concentration of the bacteria was 1.0×10 8 cfu / ml, to obtain the seed liquid; the composition of the seed tank culture medium is: 20g / L glucose, 6g / L corn steep liquor, 2g / L peptone, 0.2g / L potassium dihydrogen phosphate, 0.2g / L dihydrogen phosphate Potassium, 0.1g / L magnesium sulfate, 0.1g / L manganese sulfate, solvent is water;

[0034] Add the cell powder to 10 times the weight of the seed liquid, adjus...

Embodiment 2

[0038] The liquid fertilizer made from amino acid fermentation tail liquid is prepared according to the following process:

[0039] The amino acid fermentation tail liquid is separated by a disc separator with a rotating speed of 4000rpm and a centrifugation time of 3 minutes, collecting the bacterial sediment and waste mother liquor, drying the bacterial sediment, and then pulverizing it into bacterial powder by a pulverizer;

[0040] Aspergillus niger ATCC 6275 was inoculated into the seed tank medium for cultivation, the temperature was controlled at 30°C, and the concentration of bacteria was cultivated to 3.0×10 8 cfu / ml, to obtain the seed liquid; the composition of the seed tank culture medium is: 20g / L glucose, 6g / L corn steep liquor, 2g / L peptone, 0.2g / L potassium dihydrogen phosphate, 0.2g / L dihydrogen phosphate Potassium, 0.1g / L magnesium sulfate, 0.1g / L manganese sulfate, solvent is water;

[0041] Add the cell powder to 10 times the weight of the seed solution, a...

Embodiment 3

[0045] Effects of different treatment methods on the degree of proteolysis of bacteria:

[0046] In the present invention, taking threonine fermentation tail liquid as an example, the components are as follows (dry basis%): bacterial protein 37.8, amino acid 15.1, polysaccharides 4.9, ammonia nitrogen 10.2, sulfur 8.3, calcium 3.8, potassium 1.4, iron 1.1, the balance is other.

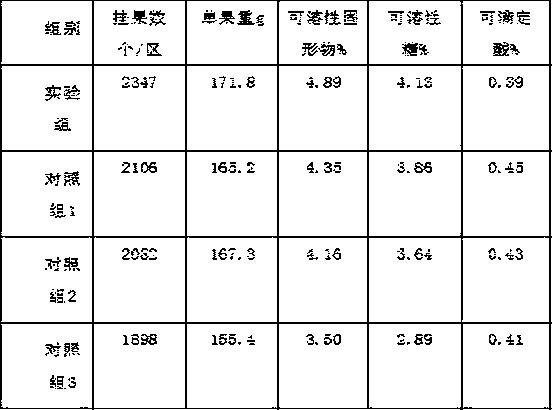

[0047] Set group:

[0048] Take embodiment 1 as experimental group;

[0049] Control group 1: 6 mol / L hydrochloric acid was used to hydrolyze bacterial protein at 60° C. for 16 hours with stirring, and the rest were the same as in Example 1.

[0050] Control group 2: 2 mol / L hydrochloric acid was used to hydrolyze the bacterial protein with stirring at 60°C for 32 hours, and the rest were the same as in Example 1.

[0051] Control group 3: do not add tourmaline powder, all the other are the same as embodiment 1;

[0052] Control group 4: the temperature is controlled at 30°C, the temperature is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com