Lignin-based binder, preparation method thereof, and lithium ion battery

A technology based on lignin and binder, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem that the capacity of silicon-based negative electrode materials cannot approach its theoretical specific capacity, and the specific capacity of silicon-based negative electrode materials cannot be maximized. problems, achieve good bonding effect, good cycle performance, and improve the effect of actual specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method at least comprises the following steps:

[0034] The lignin, the first initiator and the organic solvent are mixed to obtain a first mixed material;

[0035] adding the prepolymer to the first mixed material, heating to 30-80° C. in an inert gas atmosphere, and performing a constant temperature reaction for 6-12 hours;

[0036] After the reaction is completed, it is cooled to room temperature and purified to obtain a lignin-based binder.

[0037] The technical solutions of the present invention are further explained in detail below.

[0038] The lignin, one of the raw materials of the present invention, can be alkali lignin, lignosulfonate, sulfonated alkali lignin, sulfonated enzymatic lignin, carboxylated alkali lignin, carboxylated enzymatically hydrolyzed lignin, ammonium alkaloid At least one of lignin and ammonium enzymatic hydrolysis of lignin. The used lignin provides corresponding growth points for obtaining the final product, and afte...

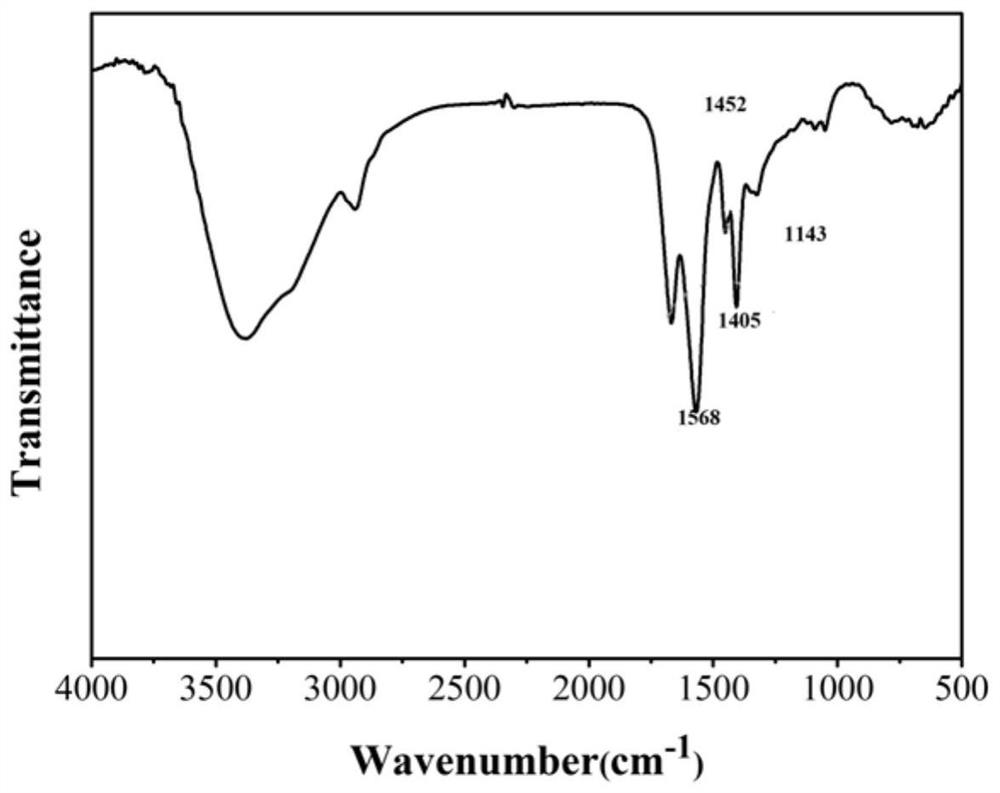

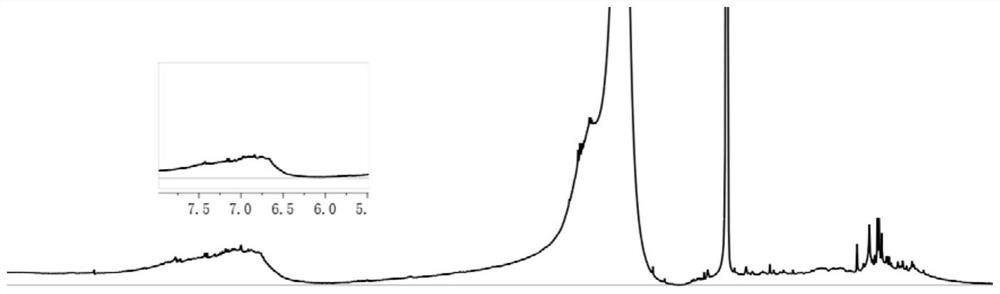

Embodiment 1

[0092] A lignin-based binder is prepared by using alkali lignin, anhydrous calcium chloride, hydrogen peroxide and polyacrylonitrile prepolymer.

[0093] The lignin-based binder is prepared by the following steps:

[0094] (1) under stirring, 10g alkali lignin, 5g anhydrous calcium chloride, 3g hydrogen peroxide, 50g DMSO are placed in the reactor that volume is 500mL and carry out mixing treatment;

[0095] (2) adding 20 g of polyacrylonitrile prepolymer to the reaction kettle treated in step (1), heating to 60° C. at a stirring speed of 250 rpm, and reacting while stirring at 60° C. The reaction time is about 6h;

[0096] (3) the reaction product solution obtained in step (2) is cooled to room temperature, and the cooled reaction solution is separated out in its deionized water, filtered, and the filtrate will be obtained; the filtrate is dissolved in DMF, filtered, and taken The filtrate is then separated out in deionized water, then continues to be solvent in DMF, and fur...

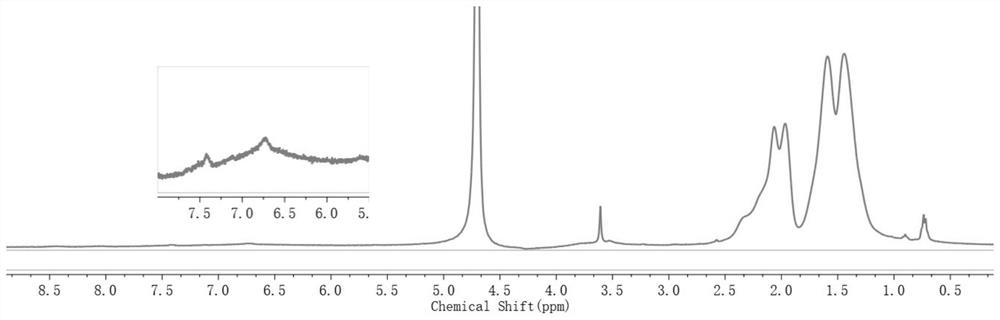

Embodiment 2

[0107] A lignin-based binder is prepared by using alkali lignin, anhydrous calcium chloride, hydrogen peroxide and polyacrylonitrile prepolymer.

[0108] The lignin-based binder is prepared by the following steps:

[0109] (1) under stirring, 10g alkali lignin, 1g anhydrous calcium chloride, 0.5g hydrogen peroxide, 50g DMF are placed in the reactor that volume is 500mL and carry out mixing treatment;

[0110] (2) adding 10 g of polyacrylonitrile prepolymer to the reaction kettle treated in step (1), heating to 60° C. at a stirring speed of 200 rpm, and reacting while stirring at 60° C. The reaction time is about 8h;

[0111] (3) the reaction product solution obtained in step (2) is cooled to room temperature, and the cooled reaction solution is separated out in its deionized water, filtered, and the filtrate will be obtained; the filtrate is dissolved in DMF, filtered, and taken The filtrate is then separated out in deionized water, then continues to be solvent in DMF, and fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com