Terahertz modulator based on silicon-based microstructure on SOI, system and method

A silicon-based microstructure and modulation system technology, applied in the field of terahertz technology and application, can solve the problems of high terahertz wave insertion loss, unfavorable terahertz imaging accuracy, and low modulation depth, so as to reduce the carrier diffusion effect, Effects of increasing resolution and increasing modulation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

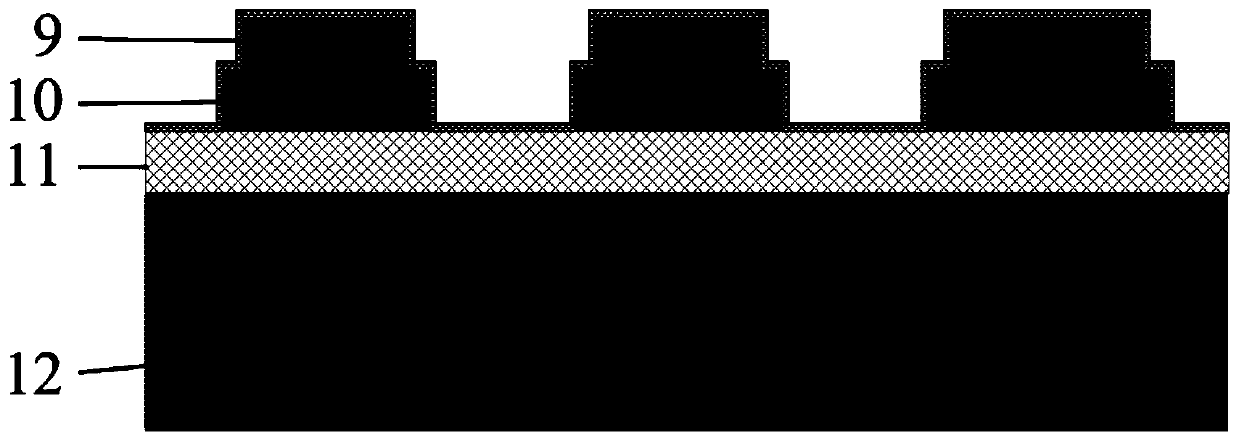

[0042] Such as figure 2 with image 3 As shown, a terahertz modulator based on a silicon-based microstructure on SOI, including from bottom to top: the underlying Al 2 o 3 Substrate 12, SiO 2 Isolation layer 11, silicon-based microstructure 10, Al 2 o 3 Passivation layer 9, silicon-based microstructures 10 are periodically arranged on the SiO2 isolation layer 11, each silicon-based microstructure 10 includes two layers of square Si-based step structures, and from top to bottom are the upper Si-based step 101 and the lower Si-based step structure respectively. The centers of the upper Si-based step 101 and the lower Si-based step 102 of the base step 102 are aligned, and the side length of the upper Si-based step 101 is smaller than the side length of the lower Si-based step 102 .

[0043] In this embodiment, the two layers of square Si-based stepped structures of the silicon-based microstructure 10 are both Si layers, the resistivity of the Si layer is greater than 3000Ω...

Embodiment 2

[0051] Such as Figure 5 As shown, the preparation method of the terahertz modulator based on the silicon-based microstructure on SOI in Example 1 includes the following steps:

[0052] Step 1: Use the electromagnetic simulation software CST Microwave Studio to carry out 3D modeling of the silicon-based microstructure. The total thickness of the model is 500 μm, and the thickness of the Si layer is 90 μm. After setting the boundary conditions and solver, the edges of the two-layer square steps The length and step height are set as variables to scan to obtain the best simulation parameters. The best parameters obtained by the final optimization are that the upper Si-based step has a side length of 66 μm and a height of 45 μm; the lower Si-based step has a side length of 84 μm and a height of 45 μm;

[0053] Step 2: Clean the SOI substrate: first put the SOI substrate into a beaker filled with acetone for ultrasonic cleaning for 10-15 minutes, then use alcohol for ultrasonic cle...

Embodiment 3

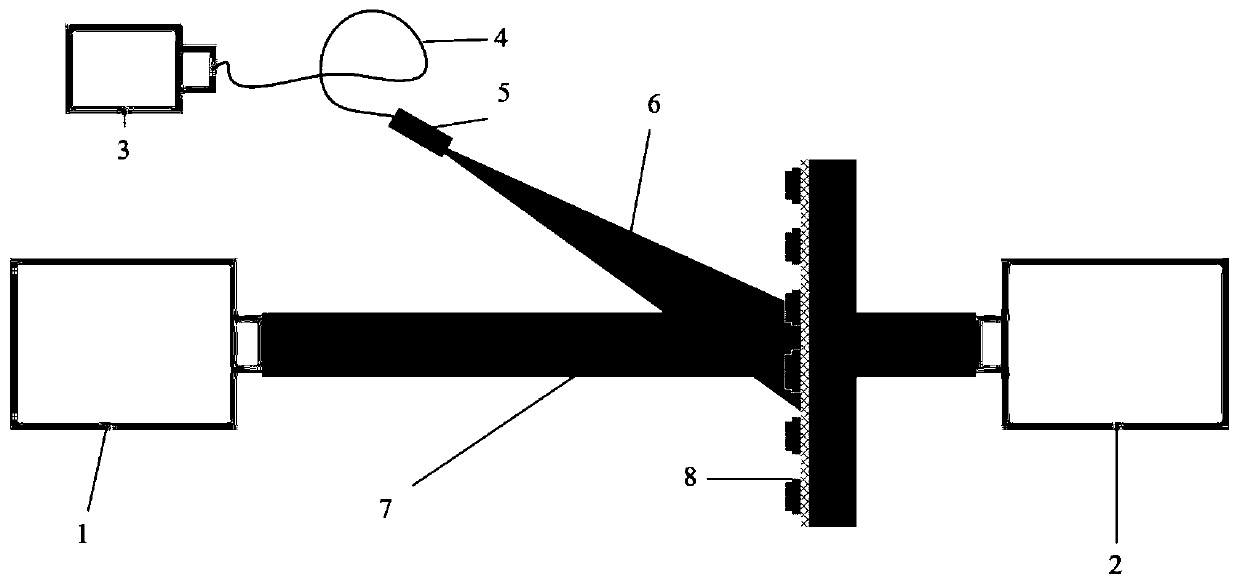

[0057] Such as figure 1 As shown, an optically controlled terahertz modulation system based on silicon-based microstructure on SOI includes: semiconductor laser 3, laser modulator 5, terahertz modulator 8, terahertz radiation source 1, terahertz detector 2, semiconductor The laser 3 is connected to the laser modulator 5 through the optical fiber 4, the laser beam 6 emitted by the laser modulator 5 is incident on the surface of the terahertz modulator 8 as the excitation laser, and the terahertz radiation source 1 and the terahertz detector 2 are located on the left and right sides of the terahertz modulator On both sides, the terahertz beam 7 emitted by the terahertz radiation source 1 passes through the terahertz modulator 8 vertically and then enters the terahertz detector 2. The incident direction of the terahertz beam 7 is that the terahertz modulator 8 has a silicon-based microstructure On one side of 10, the terahertz radiation source 1 and the terahertz detector 2 are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com