Supercapacitor electrode composite material and preparation method thereof

A technology of supercapacitors and composite materials, which is applied in the fields of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology for materials and surface science, etc. Electrode materials of capacitors, etc., to achieve the effect of strong conductivity stability, good electrochemical energy storage performance, and good capacity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a method for preparing a supercapacitor electrode composite material, which specifically includes the following steps:

[0051] (1) Preparation of nickel trimesate:

[0052] First fully dissolve 1.27g of nickel nitrate hexahydrate in 50ml of ethanol, then pour 0.513g of trimesic acid into it, stir and dissolve; then transfer the obtained solution into a 100ml reaction kettle, react at 150°C for 24 hours, pump The solid powder obtained by filtration was washed with alcohol three times, and dried in vacuum at 80° C. for 12 hours to obtain the product nickel trimesate MOFs;

[0053] (2) Preparation of nickel trimesate / MOFs:

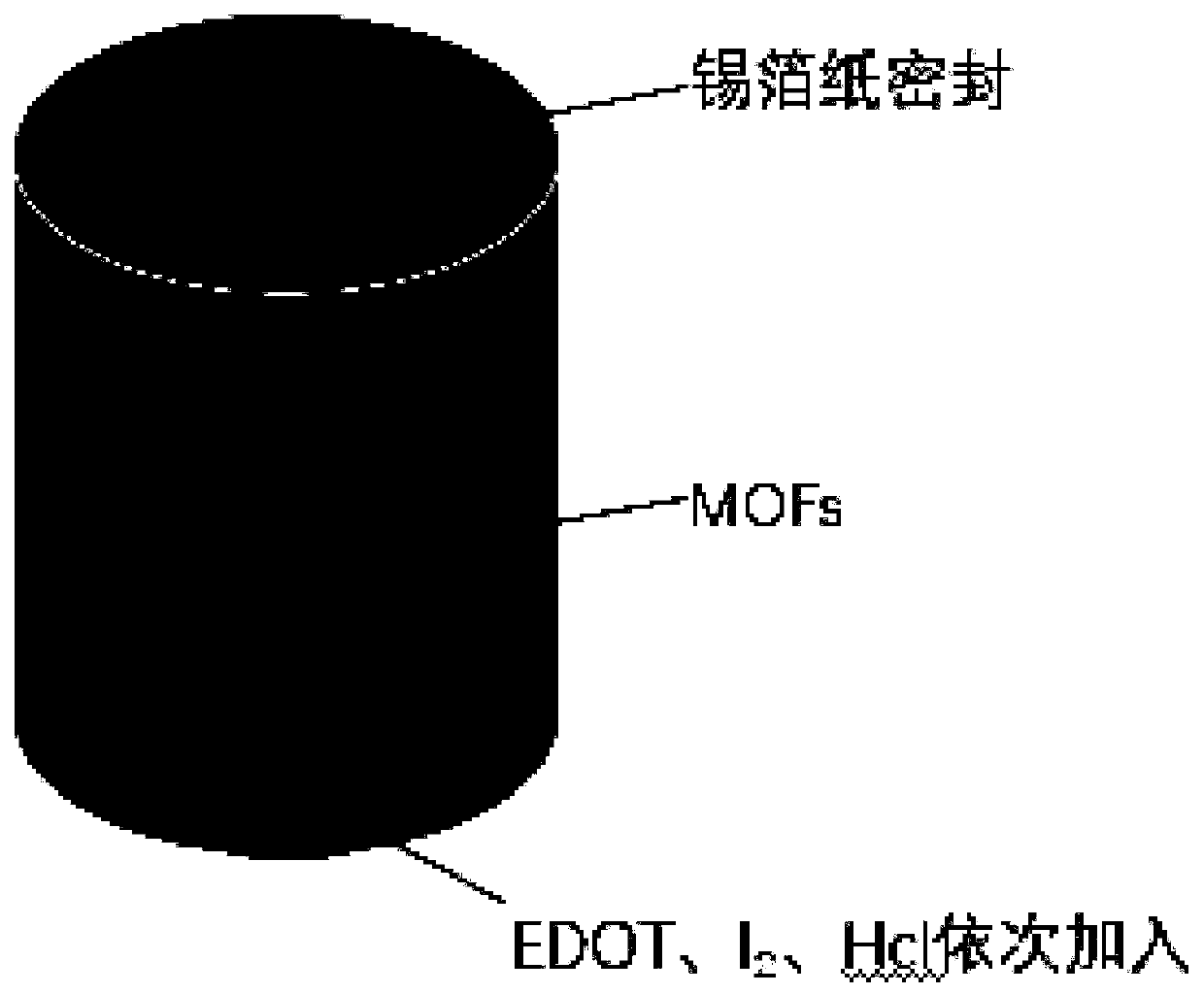

[0054] In a closed container, take 0.15g of the obtained nickel trimesate MOFs and put them on a filter paper with a diameter of 50mm and a pore size of 0.22um, and place it at a high place. The schematic diagram of the device used in the laboratory is as follows figure 1 , put 1ml EDOT under it, and fumigate for 12 hours at...

Embodiment 2

[0060] (1) Preparation of nickel trimesate:

[0061] First fully dissolve 1.27g of nickel nitrate hexahydrate in 50ml of ethanol, then pour 0.513g of trimesic acid into it, stir and dissolve; then transfer the obtained solution into a 100ml reaction kettle, react at 150°C for 24 hours, pump The solid powder obtained by filtration was washed with alcohol three times, and dried in vacuum at 80° C. for 12 hours to obtain the product nickel trimesate MOFs;

[0062] (2) Preparation of nickel trimesate / MOFs:

[0063] In an airtight container, take 0.15 g of the obtained nickel trimesate MOFs and place it on a filter paper with a diameter of 50 mm and a pore size of 0.22 um, and place it in a high place, as shown in the schematic diagram below figure 1 , put 1ml EDOT under it, and fumigate for 12 hours at room temperature 30°C; place 0.3g I 2 , high temperature oxidation at 100°C for 10 hours; then at I 2 1ml of 12mol / L concentrated hydrochloric acid was placed at the place where ...

Embodiment 3

[0065] (1) Preparation of nickel trimesate:

[0066] First fully dissolve 1g of nickel nitrate hexahydrate in 50ml of ethanol, then pour 0.3g of trimesic acid into it, stir and dissolve; then transfer the obtained solution into a 100ml reactor, react at 150°C for 12 hours, and filter with suction The obtained solid powder was washed with alcohol for three times, and dried in vacuum at 80° C. for 12 hours to obtain the product nickel trimesate MOFs;

[0067] (2) Preparation of nickel trimesate / MOFs:

[0068] In an airtight container, take 0.15 g of the obtained nickel trimesate MOFs and place it on a filter paper with a diameter of 50 mm and a pore size of 0.22 um, and place it in a high place, as shown in the schematic diagram below figure 1 , put 0.5ml EDOT under it, and fumigate for 10 hours at room temperature 20°C; place 0.3g I 2 , high temperature oxidation at 90°C for 8 hours; then at I 2 Place 0.5ml of 12mol / L concentrated hydrochloric acid at the place where it is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com