Micro-nano bubble releasing material for repairing natural water body and preparation method thereof

A technology for water body restoration and material release, applied in water aeration, separation methods, chemical instruments and methods, etc., can solve problems such as increasing the concentration of nitrate nitrogen in water bodies, high power and operating costs, and remediation of water bodies that are difficult to anoxic. Achieve the effect of no secondary pollution, improve self-purification ability, and abundant reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

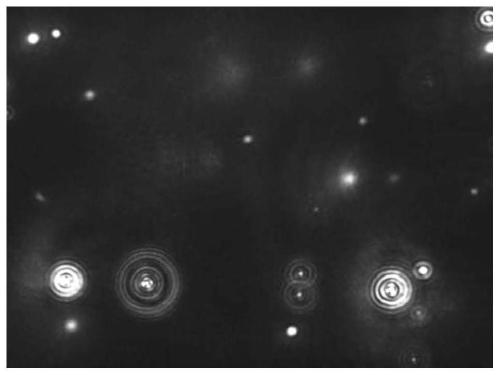

[0024] The oxygen micro-nano bubble release performance of embodiment 1 natural zeolite

[0025] The natural clinoptilolite is ground and sieved, the 2-4mm particles are taken, fully washed with deionized water and the powdery particles are washed out, drained and dried overnight at 80°C, taken out and placed in a muffle furnace at 350°C Burn for 4 hours, cool down and set aside. Take a certain amount of washed and fully dehydrated zeolite samples and place them in a closed stainless steel device with independent inlet valves and exhaust valves and withstand a certain high pressure and vacuum degree for vacuum pressure swing adsorption. The vacuum condition is set to -0.09MPa for 2h , O 2 The high-pressure adsorption condition is 0.45MPa for 0.5h, and the vacuum swing operation steps are cycled 3 times, and the last high-pressure equilibrium time is not less than 12h. After the material is depressurized, it is immediately put into a plexiglass column (inner diameter 64mm, he...

Embodiment 2

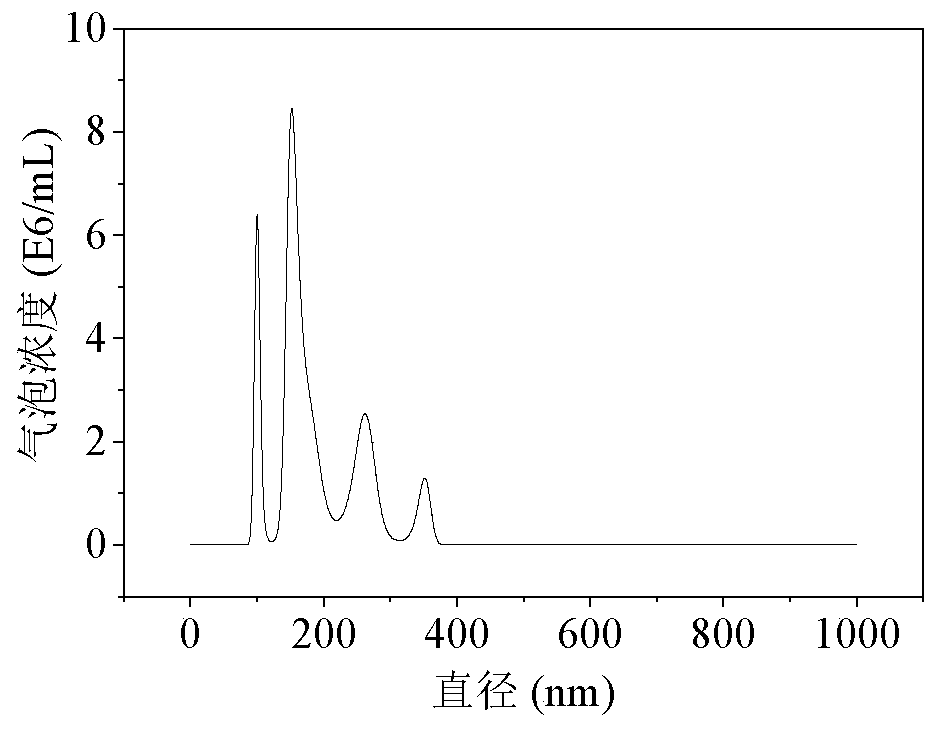

[0026] The particle size distribution of the oxygen nano-bubbles released by the natural zeolite of embodiment 2

[0027] The natural clinoptilolite is ground and sieved, and the particles of 0.35-0.60mm are taken, fully washed with deionized water and the powdery particles are washed out, drained and dried overnight at 80°C, taken out and placed in a muffle furnace at 350°C Under burning 4h, cooling stand-by. Take a certain amount of washed and fully dehydrated zeolite samples and place them in a closed stainless steel device with independent inlet valves and exhaust valves and withstand a certain high pressure and vacuum degree for vacuum pressure swing adsorption. The vacuum condition is set to -0.09MPa for 2h , O 2 The high-pressure adsorption condition is 0.15MPa for 0.5h, and the cycle vacuum swing operation steps are 3 times, and the last high-pressure equilibrium time is not less than 12h. After the material is decompressed, put it into a beaker filled with ultrapure...

Embodiment 3

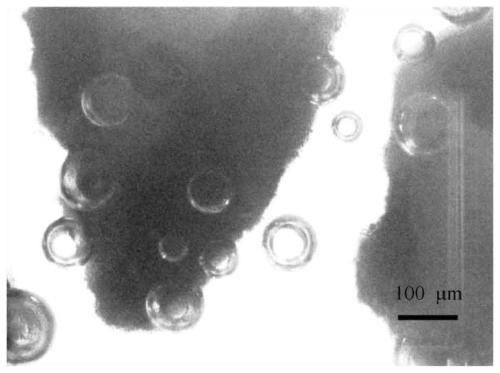

[0028] Embodiment 3 Air Micro Bubble Morphology Released by Diatomite Mineral Particles

[0029] The natural mineral diatomite is ground and sieved, and the particles of 0.355-0.425mm are taken, fully washed with deionized water and the powdery particles are washed out, after draining the water, dry at 80°C overnight, take it out and put it in a vacuum oven at 90°C Medium treatment for 12 hours, the pressure is less than -0.095MPa, and the temperature is lowered for later use. Take a certain amount of processed diatomite particles and place them on a glass slide, submerge them with ultra-pure water with a plastic dropper, use an inverted microscope to observe the process of diatomite releasing micro-bubbles, and take pictures of the micro-bubbles released by it Photo( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com