Novel high-temperature-resistant glass tube and processing technique thereof

A processing technology and high temperature resistance technology, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of easy cracking or breaking, and the high temperature resistance of glass is not ideal, and achieve the effect of preventing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

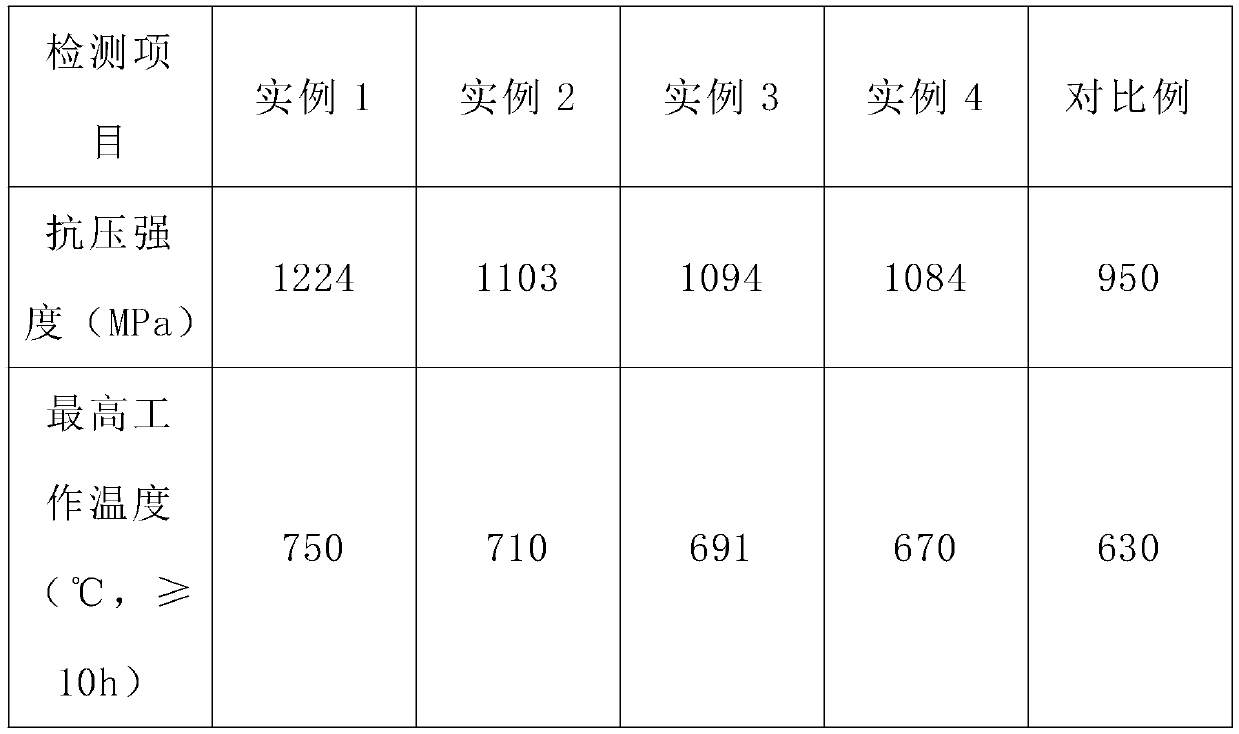

Examples

example 1

[0045] A new type of high temperature resistant glass tube, including the following raw materials in parts by weight: 30 parts of pretreatment mixture, 60 parts of modified quartz powder, 3 parts of polydimethylsiloxane, 3 parts of pigment, 8 parts of sodium oxide, 5 parts boron oxide, 2 parts potassium fluozirconate, 2 parts strontium carbonate.

[0046] The pigment is chrome yellow.

[0047] A processing technology of a novel high temperature resistant glass tube, the processing process of the novel high temperature resistant glass tube is:

[0048] (1) In parts by weight, take 30 parts of quartz powder, 5 parts of corundum powder, 3 parts of peach gum, and 100 parts of water, put peach gum and water in a beaker, stir with a glass rod for 20 minutes, and let it stand for swelling for 5 hours Afterwards, place the beaker in a magnetic stirrer with digital speed measurement and constant temperature, heat and stir to dissolve for 60 minutes at a temperature of 95°C and a speed...

example 2

[0056] A new type of heat-resistant glass tube, including the following raw materials in parts by weight: 30 parts of pretreatment mixture, 60 parts of quartz powder, 3 parts of polydimethylsiloxane, 3 parts of pigment, 8 parts of sodium oxide, 5 parts of Boron oxide, 2 parts potassium fluozirconate, 2 parts strontium carbonate.

[0057] The pigment is chrome yellow.

[0058] A processing technology of a novel high temperature resistant glass tube, the processing process of the novel high temperature resistant glass tube is:

[0059](1) In parts by weight, 40 parts of rice husk fibers, 3 parts of wood rot fungi, 5 parts of glucose solution, 60 parts of water, 0.2 part of sodium fluoride, 60 parts of hydrochloric acid, 20 parts of ferric nitrate solution are taken successively, and rice The shell fiber and hydrochloric acid were placed in a single-necked flask, stirred, mixed and soaked for 3 hours at a rotating speed of 800r / min, then filtered to obtain No. 1 filter cake, and...

example 3

[0065] A new type of high temperature resistant glass tube, including the following raw materials in parts by weight: 30 parts of pretreatment mixture, 60 parts of modified quartz powder, 3 parts of polydimethylsiloxane, 3 parts of pigment, 8 parts of sodium oxide, 5 parts boron oxide, 2 parts potassium fluozirconate, 2 parts strontium carbonate.

[0066] The pigment is chrome yellow.

[0067] A processing technology of a novel high temperature resistant glass tube, the processing process of the novel high temperature resistant glass tube is:

[0068] (1) In parts by weight, take 30 parts of quartz powder, 5 parts of corundum powder, 3 parts of peach gum, and 100 parts of water, put peach gum and water in a beaker, stir with a glass rod for 20 minutes, and let it stand for swelling for 5 hours Afterwards, place the beaker in a magnetic stirrer with digital speed measurement and constant temperature, heat and stir to dissolve for 60 minutes at a temperature of 95°C and a speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com