A kind of erythromycin thiocyanate enteric-coated pellets and preparation method thereof

A technology of erythromycin thiocyanate and enteric-coated pellets, applied in the field of veterinary medicine, can solve problems such as poor oral palatability, and achieve the effects of improving stability and improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

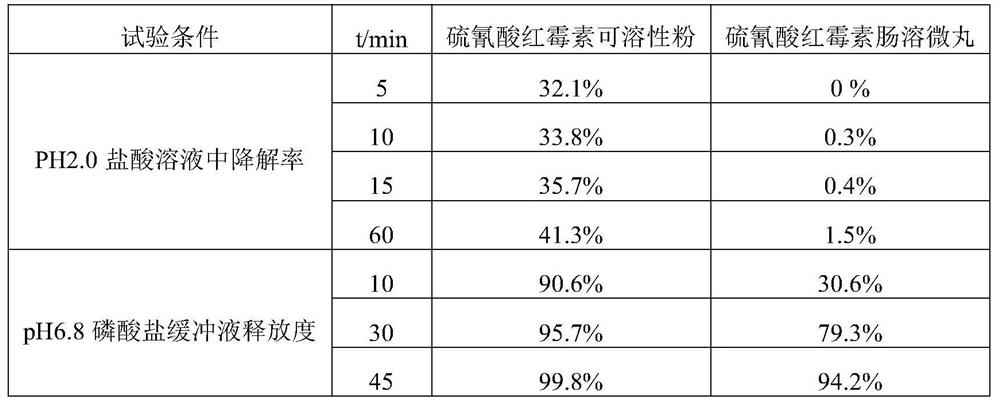

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Table 1 10% content specification prescription

[0036] Name of raw material Amount added (g) Erythromycin Thiocyanate 10 (converted content) Low-substituted hydroxypropyl cellulose 2 sucrose 10 Mannitol added to 85 2% Hydroxypropyl Cellulose 80 Cellulose acetate phthalate 10 Titanium dioxide 2.0 polyethylene glycol 400 3.0 acetone 80

[0037] Preparation process

[0038] (1) Take by weighing erythromycin thiocyanate, low-substituted hydroxypropyl cellulose, sucrose and mannitol and mix uniformly by prescription quantity;

[0039] (2) Take 1.6g of hypromellose by weighing according to the prescription quantity and throw it into 80g of purified water, cut and dissolve for 15min, and obtain the adhesive;

[0040] (3) Put the powder in step (1) into the tank mixer machine, mix with the binder of step (2) to prepare soft material, and discharge;

[0041] (4) Add the soft material prepared in step (3) to...

Embodiment 2

[0046] Table 2 30% content specification prescription

[0047] Name of raw material Amount added (g) Erythromycin Thiocyanate 30 (converted content) Crospovidone 2 sucrose 10 Dextrin added to 70 1% hypromellose 65 Hydroxypropyl Methyl Cellulose Phthalate 27 silica 5.0 Triacetin 2.0 40% ethanol in water 80

[0048] Preparation process

[0049] (1) take erythromycin thiocyanate, polyvinylpolypyrrolidone, sucrose and dextrin and mix uniformly by recipe quantity;

[0050] (2) Take 0.65g of hypromellose by weighing according to the prescription quantity and throw it into 65g of purified water, cut and dissolve for 15min, and obtain the adhesive;

[0051] (3) Put the powder in step (1) into the tank mixer machine, mix with the binder of step (2) to prepare soft material, and discharge;

[0052] (4) Add the soft material prepared in step (3) to the spherical extruder for 45 rotations to extrude, and spheronize in...

Embodiment 3

[0057]Table 3 20% content specification prescription

[0058] Name of raw material Amount added (g) Erythromycin Thiocyanate 20 (converted content) Carboxymethyl Starch Sodium 2 microcrystalline cellulose 30 starch added to 80 1%pvpk30 76 Acrylic 14 silica 3.0 triethyl citrate 3.0 acetone 70

[0059] Preparation process

[0060] (1) take by weighing erythromycin thiocyanate, sodium starch glycolate, microcrystalline cellulose and starch by recipe quantity and mix;

[0061] (2) Weigh 0.76g pvpk30 according to the prescription amount and drop it into 76g purified water, cut and dissolve for 15min to obtain the adhesive;

[0062] (3) Put the powder in step (1) into the tank mixer machine, mix with the binder of step (2) to prepare soft material, and discharge;

[0063] (4) Add the soft material prepared in step (3) to the spherical extruder for 45 rotations to extrude, and spheronize in the spheronizer at 600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| release amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com