A laminated structure for enhancing the fluorescence luminous intensity of luminescent film and its preparation method

A technology of stacked structure and luminous intensity, applied in the field of luminescent materials, can solve the problems of high electron drift saturation speed, insignificant luminous enhancement effect, and low luminous intensity of materials, and achieve enhanced luminous intensity, low preparation cost, and time-consuming process short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

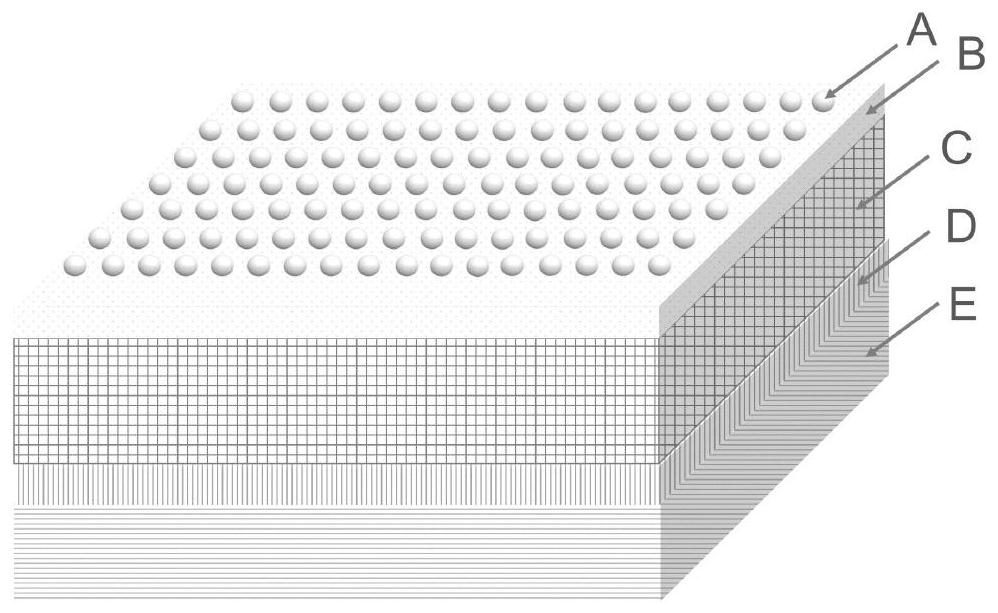

[0056] An embodiment of the present invention provides a laminated structure that enhances the fluorescence luminous intensity of a luminescent film, specifically as figure 1 As shown, it includes a single-layer dielectric microsphere array, a second metal nanoparticle layer, a luminescent film, a first metal nanoparticle layer and a substrate that are sequentially stacked and connected; the preparation method includes:

[0057] (1) cleaning and drying the substrate;

[0058] (2) Using a vacuum ion sputtering apparatus, selecting a suitable metal target, adjusting the pressure of the sample chamber and the sputtering current, and sputtering the first metal nanoparticle layer on the surface of the substrate;

[0059] (3) Prepare a luminescent film on the upper surface of the first metal nanoparticle layer by molecular beam epitaxy, magnetron sputtering or pulse laser deposition. For example, the specific steps for preparing a luminescent film zinc oxide luminescent film by puls...

Embodiment 1

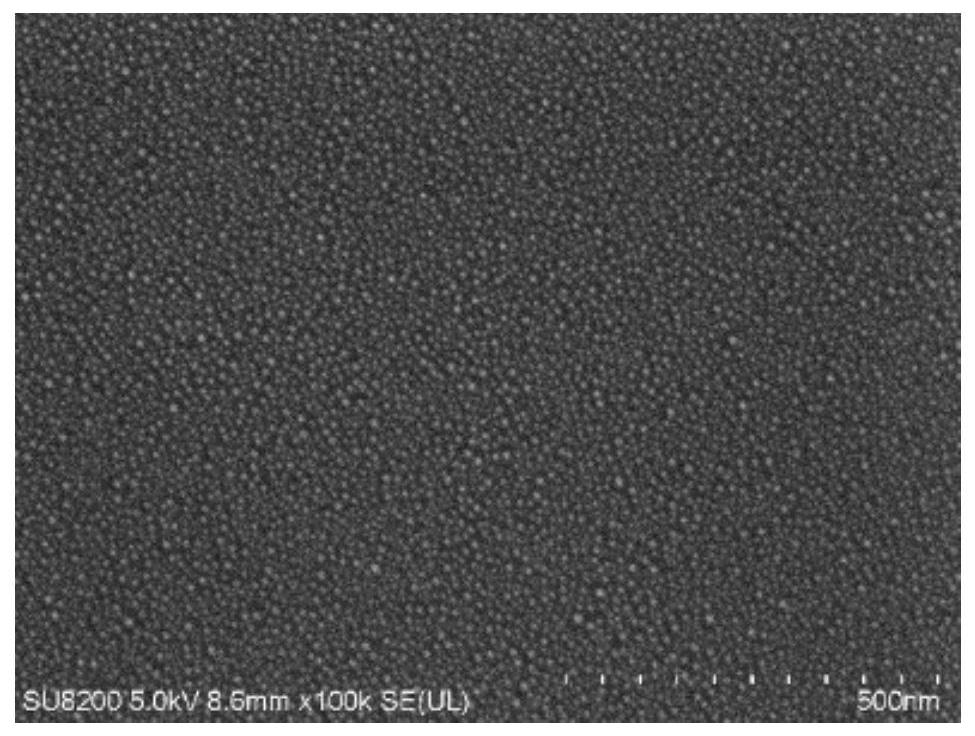

[0063] Clean the alumina single crystal substrate, and after it is naturally dried at room temperature, put it on the sample stage of the ion sputtering instrument. The sputtering time is set to 30s, so that the gold nanoparticles are uniformly deposited on the alumina substrate, and the particle size of the nanoparticles is about 16nm. The scanning electron microscope micrograph of the prepared gold nanoparticles is as follows figure 2 shown.

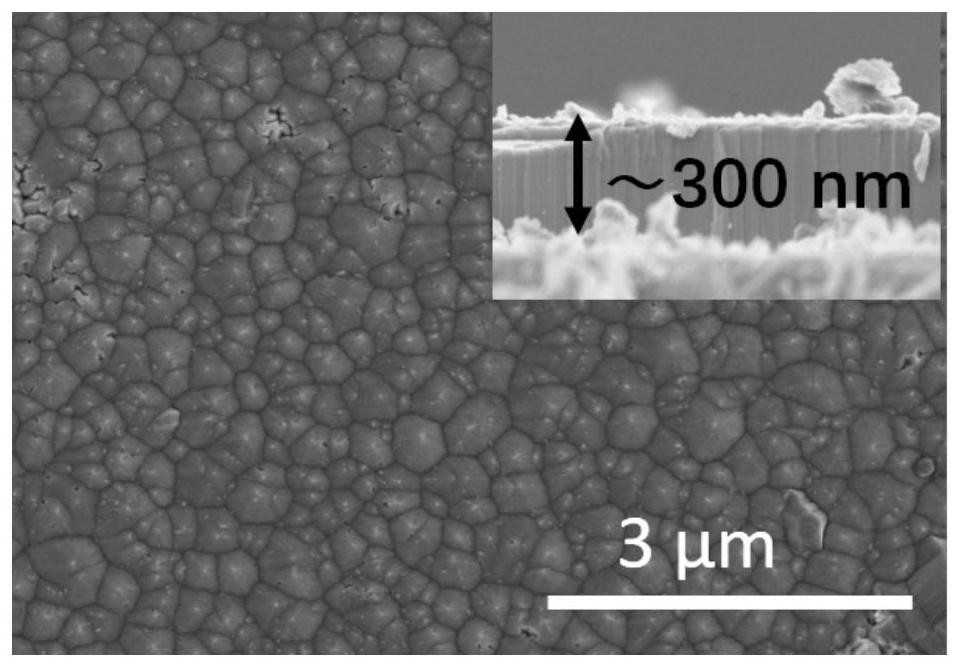

[0064] Put the prepared sample containing gold nanoparticles on the silicon plate heater in the deposition chamber of the pulse laser deposition instrument, use the mechanical pump to pump the deposition chamber to 2.0 Pa, then turn on the molecular pump to draw a high vacuum until the vacuum degree reaches 10 -4 When Pa is about, turn off the molecular pump; then pass a certain amount of oxygen into the deposition chamber, adjust the current of the silicon plate to slowly increase the temperature to 400°C, then focus the KrF excimer ...

Embodiment 2

[0069] The preparation process of the embodiment of the present invention is similar to that of embodiment 1, the difference is that when preparing aluminum nanoparticles by sputtering, the sputtering time is 24s; in addition, when configuring the dielectric microsphere suspension, the diameter is 1.5 μm transparent dielectric microspheres were mixed with ethanol at a concentration of 1×10 6 µL -1 .

[0070] Using 325nm ultraviolet excitation light to excite the film, the resulting 376nm wavelength luminous intensity a is 101 times that of the pure zinc oxide film luminous intensity b, the results are as follows Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com