High-purity EPA glyceride and DHA glyceride preparation method

A glycerol ester enzymatic method and technology of glyceride, applied in the biological field, can solve the problems of small molecular distillation equipment capacity, complex production process, difficult large-scale production, etc., to reduce food safety risks, high product safety, and mild process conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

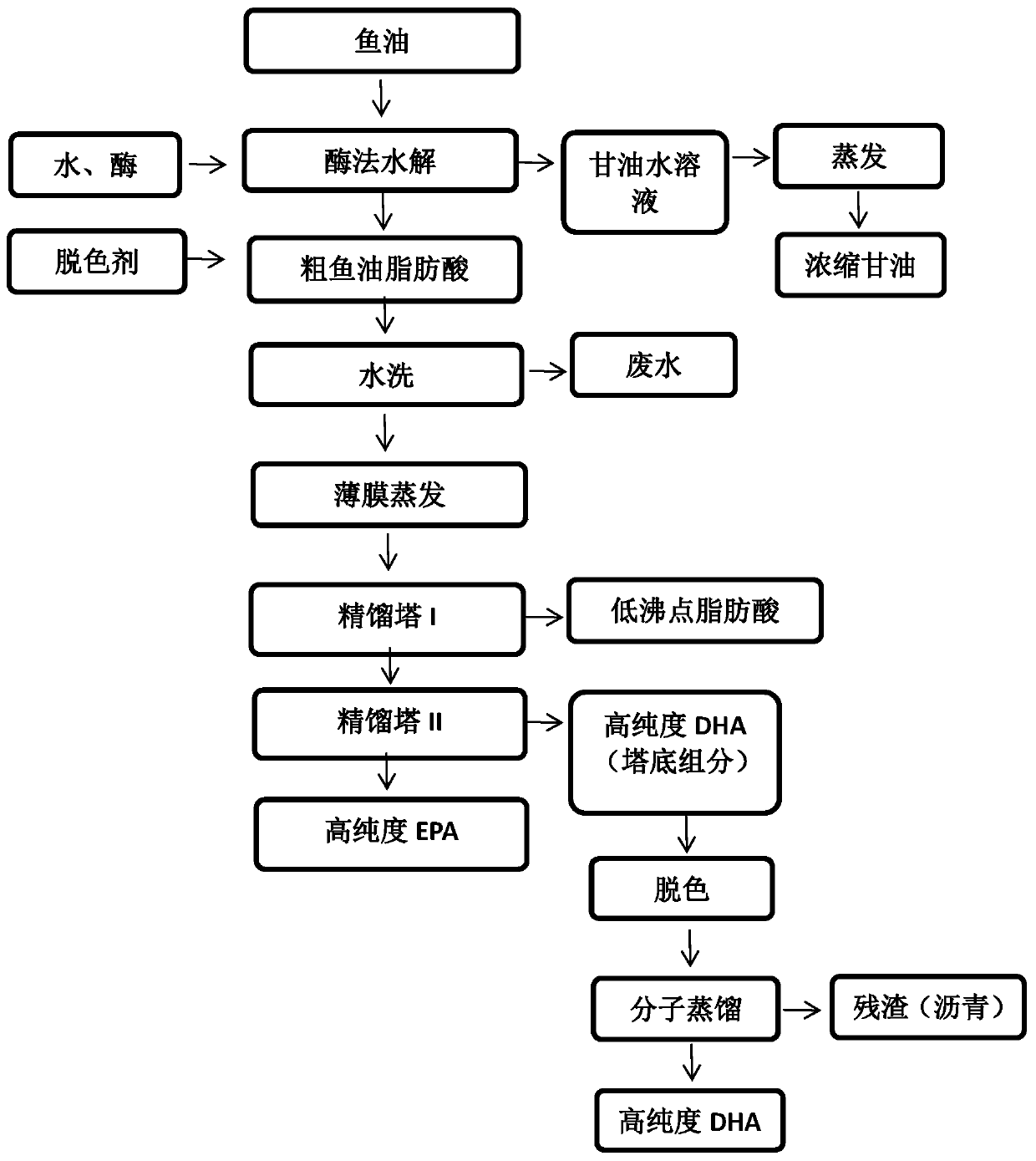

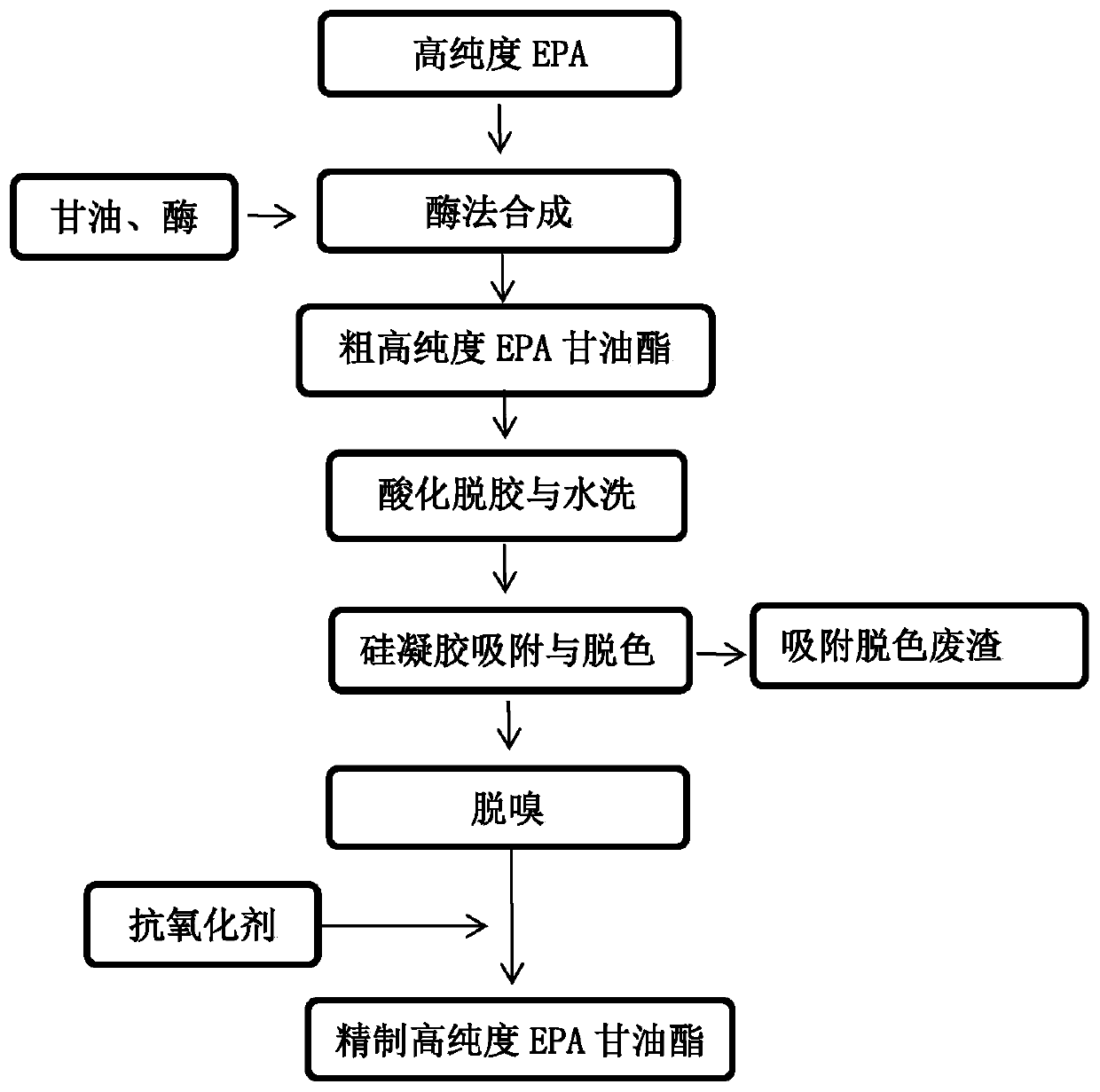

[0046] A kind of preparation method of high-purity EPA glyceride and DHA glyceride of the present embodiment comprises the steps:

[0047] (1) Enzymatic hydrolysis of fish oil: inject water, fish oil, and glyceride hydrolase into the fish oil enzymatic hydrolysis reactor, the addition of water is 15% of the weight of the fish oil, and the addition of glyceride hydrolase is 0.01% of the weight of fish oil %, stirring, adjusting the pH value of the reaction emulsion to 1.5-11.5, carrying out a countercurrent continuous hydrolysis tower under the condition of stirring to realize continuous reaction, the reaction temperature is 35°C, the reaction residence time is 72h, and the reaction product is fish oil fatty acid and glycerol aqueous solution;

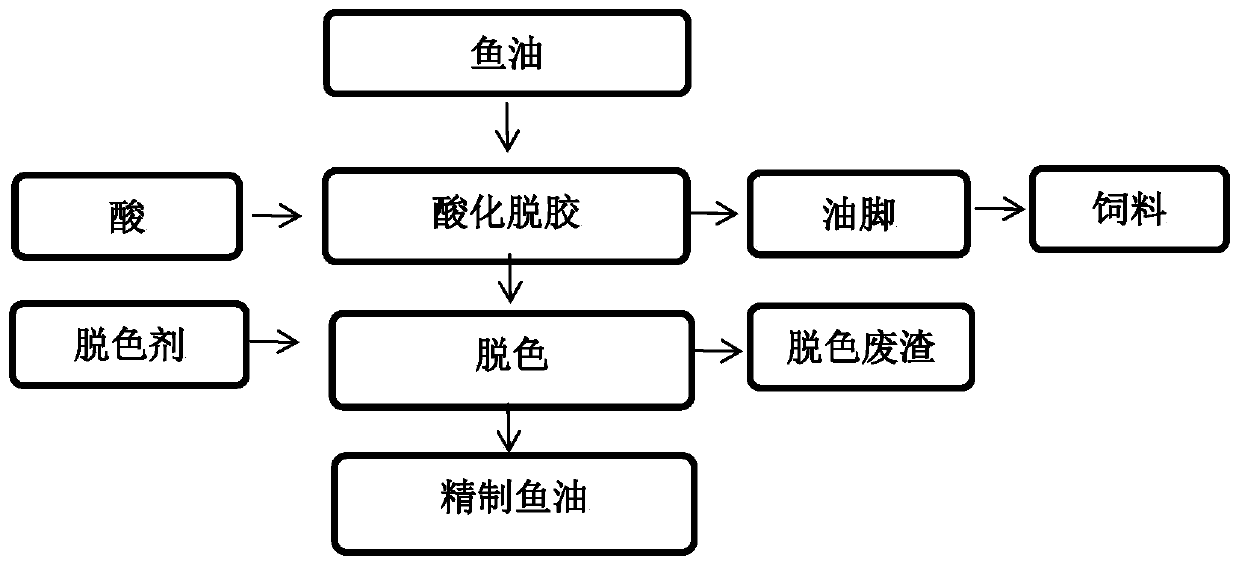

[0048] Wherein, the fish oil is anchovy fish oil, which is a semi-refined fish oil prepared by degumming and decolorizing anchovy hair oil; the specific preparation method of the semi-refined fish oil is as follows:

[0049] (a) Acidify...

Embodiment 2

[0056] A kind of preparation method of high-purity EPA glyceride and DHA glyceride of the present embodiment comprises the steps:

[0057] (1) Enzymatic hydrolysis of fish oil: inject water, fish oil, glyceride hydrolase into the fish oil enzymolysis reactor, the addition of water is 85% of the weight of the fish oil, and the addition of glyceride hydrolase is 1.76% of the weight of fish oil %, stirring, adjusting the pH value of the reaction emulsion to 1.5-11.5, performing intermittent reaction under the condition of stirring, the reaction temperature is 70°C, the reaction residence time is 37.5h, and the reaction product is an aqueous solution of fish oil fatty acid and glycerin;

[0058] Wherein, the fish oil is anchovy fish oil, which is a semi-refined fish oil prepared by degumming and decolorizing anchovy hair oil; the specific preparation method of the semi-refined fish oil is as follows:

[0059] (a) Acidify the phosphoric acid or citric acid aqueous solution in the c...

Embodiment 3

[0066] A kind of preparation method of high-purity EPA glyceride and DHA glyceride of the present embodiment comprises the steps:

[0067] (1) Enzymatic hydrolysis of fish oil: inject water, fish oil, glyceride hydrolase into the fish oil enzymolysis reactor, the addition of water is 150% of the weight of the fish oil, and the addition of glyceride hydrolase is 3.5% of the weight of fish oil %, stirring, adjusting the pH value of the reaction emulsion to 1.5-11.5, performing intermittent reaction under the condition of stirring, the reaction temperature is 90°C, the reaction residence time is 3h, and the reaction product is an aqueous solution of fish oil fatty acid and glycerin;

[0068] Wherein, the fish oil is anchovy fish oil, which is a semi-refined fish oil prepared by degumming and decolorizing anchovy hair oil; the specific preparation method of the semi-refined fish oil is as follows:

[0069] (a) Acidify the phosphoric acid or citric acid aqueous solution in the crud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com