Preparation method of high-activity catalyst used for catalyzing isomerization of glucose

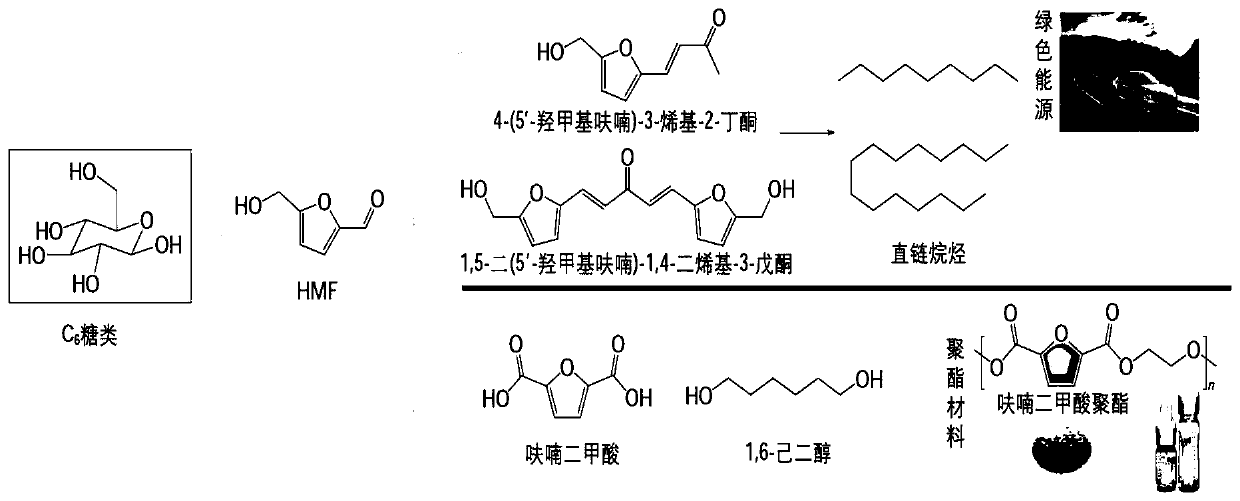

A high-activity catalyst, glucose technology, applied in physical/chemical process catalysts, preparation of sugar derivatives, chemical instruments and methods, etc., can solve the problems of decreased selectivity of fructose, poor activity stability, long reaction time, etc., to increase contact effect of sites, excellent dispersibility, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

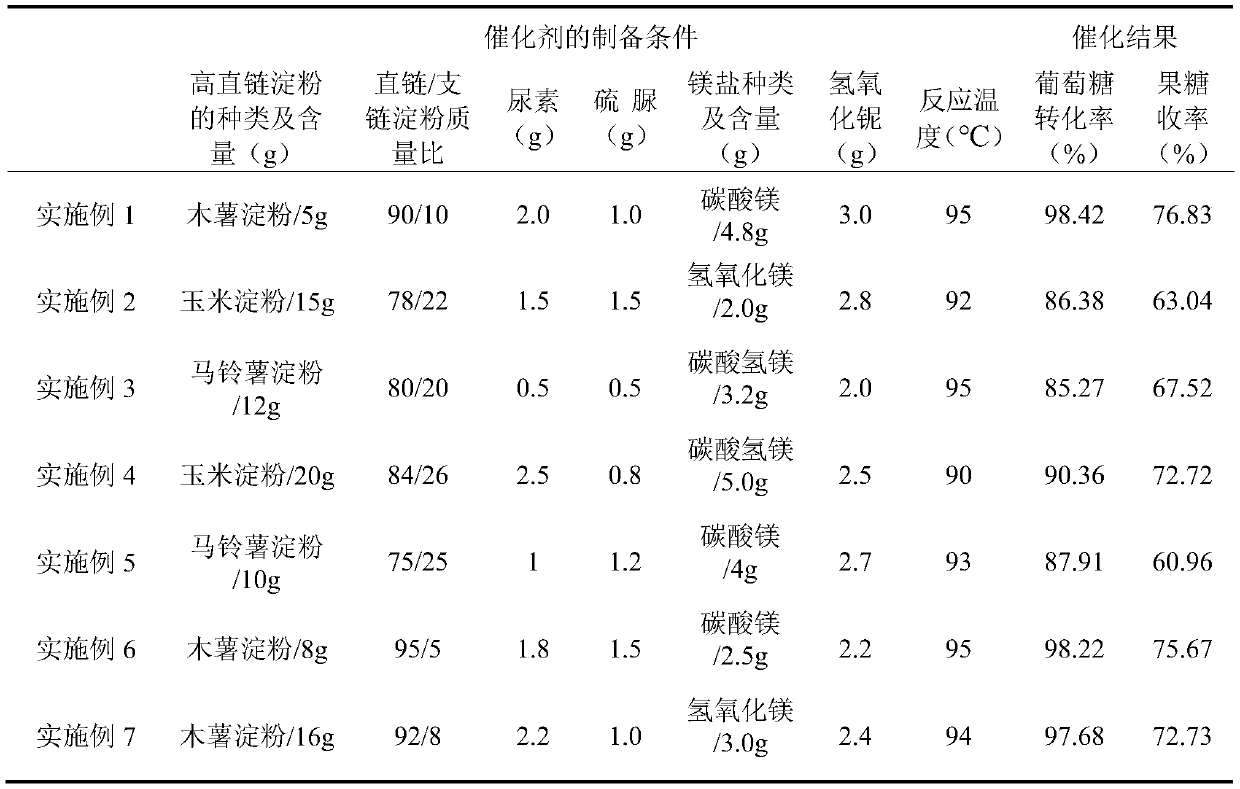

Examples

Embodiment 1

[0031] A method for preparing a highly active catalyst for catalyzing glucose isomerization, comprising the following steps:

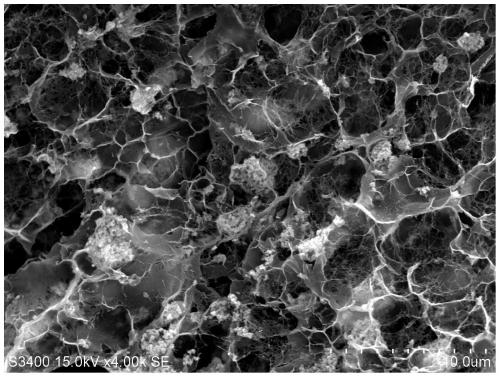

[0032] (1) Pour 3 parts by weight of high amylose starch, 1 part by weight of urea, 0.5 parts by weight of thiourea, 2 parts by weight of magnesium salt, 2 parts by weight of niobium hydroxide and 100 parts by weight of deionized water into a glass container In the process, heat to 90°C at a stirring speed of 1200r / min, continue stirring for 30min, quickly pour the reaction material into liquid nitrogen and freeze for 60min, then freeze-dry at -0.1MPa and -50°C for 72h to obtain starch-based Aerogel;

[0033] (2) Place the above starch-based airgel in a vacuum tube furnace, heat it to 1100°C in an inert gas atmosphere and keep it for 120min, then cool it down to room temperature naturally, wash it with a large amount of deionized water, collect the precipitate by filtration, and heat it at 60°C Vacuum-dry for 24 hours to obtain black catalyst powder. ...

Embodiment 2

[0035] A method for preparing a highly active catalyst for catalyzing glucose isomerization, comprising the following steps:

[0036] (1) 10 parts by weight of high amylose starch, 1.5 parts by weight of urea, 1 part by weight of thiourea, 3 parts by weight of magnesium salt, 2.2 parts by weight of niobium hydroxide and 100 parts by weight of deionized water are poured into a glass container , heated to 91°C at a stirring speed of 1400r / min, continued to stir for 30min, quickly poured the reaction material into liquid nitrogen for 60min, and then freeze-dried at -0.1MPa and -50°C for 72h to obtain starch-based Aerogel;

[0037] (2) Place the above starch-based airgel in a vacuum tube furnace, heat it to 1100°C in an inert gas atmosphere and keep it for 120min, then cool it down to room temperature naturally, wash it with a large amount of deionized water, collect the precipitate by filtration, and heat it at 60°C Vacuum-dried for 24 hours to obtain black catalyst powder.

Embodiment 3

[0039] A method for preparing a highly active catalyst for catalyzing glucose isomerization, comprising the following steps:

[0040] (1) 11 parts by weight of high amylose starch, 1.6 parts by weight of urea, 0.8 parts by weight of thiourea, 2.7 parts by weight of magnesium salt, 2.1 parts by weight of niobium hydroxide and 100 parts by weight of deionized water are poured into a glass container In the process, heat to 94°C at a stirring speed of 1300r / min, continue stirring for 30min, quickly pour the reaction material into liquid nitrogen and freeze for 60min, freeze-dry at -0.1MPa, -50°C for 72h, and obtain starch-based Aerogel;

[0041] (2) Place the above starch-based airgel in a vacuum tube furnace, heat it to 1100°C in an inert gas atmosphere and keep it for 120min, then cool it down to room temperature naturally, wash it with a large amount of deionized water, collect the precipitate by filtration, and heat it at 60°C Vacuum-dry for 24 hours to obtain black catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com