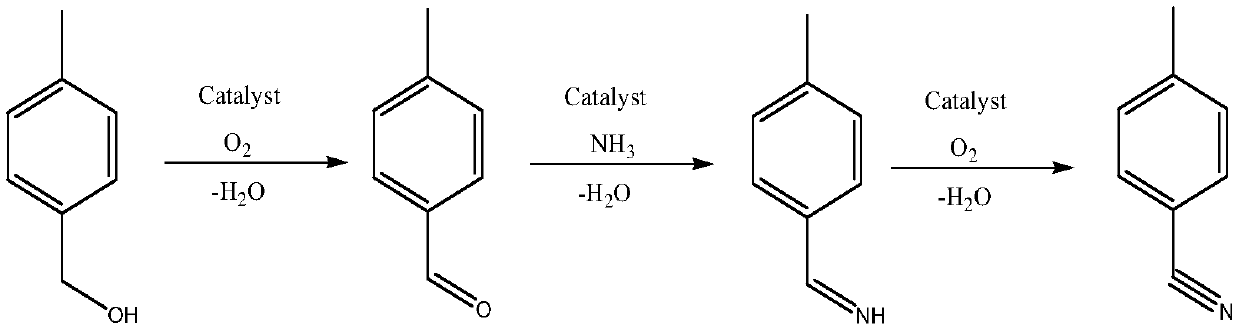

Method for preparing p-methylbenzonitrile through ammoxidation of p-methylbenzyl alcohol

A technology of p-toluene alcohol and tolunitrile, which is applied in the preparation of hydrocarbon ammoxidation, chemical instruments and methods, organic chemistry, etc., can solve the problems of large waste water discharge, serious environmental pollution, and large power consumption, and achieve Ease of separation, high catalytic selectivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First weigh 1.83g of cobalt acetate hexahydrate and 5.61g of 1-ethyl-3-methylimidazolium hydrobromide into a 100ml beaker, stir well, add 2.0g of carbon powder, 40ml of ethanol, continue to stir for 12 hours before using Ethanol was removed by a rotary evaporator, dried and ground into powder, calcined in a tube furnace at a constant temperature of 700°C for 2 hours, and naturally cooled to obtain a Co-N-C catalyst. Take 0.2g of catalyst, 0.345g of p-methylbenzyl alcohol, 1.5ml of ammonia water, 25ml of tert-amyl alcohol, and 5bar of oxygen in a high-pressure reactor, the stirring rate is 400r / min, 130°C, react for 20 hours, and p-methylbenzyl alcohol is converted The rate is 100%, and the selectivity to p-methylbenzonitrile is 100%.

Embodiment 2

[0038] First weigh 1.83g of cobalt nitrate hexahydrate, add 3.93g of 4,4-bipyridine into a 100ml beaker, add 2.0g of carbon powder and 40ml of ethanol after stirring well, continue to stir for 12 hours, remove the ethanol with a rotary evaporator, and dry it Grind into powder, calcined in a tube furnace at a constant temperature of 700°C for 2 hours, and cooled naturally to obtain a Co-N-C catalyst. Get 0.2g catalyzer, 0.345g p-methyl benzyl alcohol, 1.5ml ammonia water, 25ml toluene, 5bar oxygen in autoclave, stirring speed is 400r / min, 150 ℃, reaction 22 hours, p-methyl benzyl alcohol conversion rate is 100%, 100% selectivity to p-methylbenzonitrile.

Embodiment 3

[0040] First weigh 1.83g of cobalt chloride hexahydrate, add 2.53g of 2-methylimidazole into a 100ml beaker, stir well, add 2.0g of carbon powder, 40ml of ethanol, continue to stir for 12 hours, remove the ethanol with a rotary evaporator, and dry it Grind into powder, calcined in a tube furnace at a constant temperature of 700°C for 2 hours, and cooled naturally to obtain a Co-N-C catalyst. Get 0.2g catalyst, 0.345g p-methylbenzyl alcohol, 1.5ml ammonia water, 25ml tetrahydrofuran, 5bar oxygen in the autoclave, stirring speed is 400r / min, 110 ℃, reaction 24 hours, p-methylbenzyl alcohol conversion rate is 100%, 100% selectivity to p-methylbenzonitrile.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com