An electrolytic water catalyst with an unconventional local structure and its preparation method

A technology for electrolysis of water and catalysts, which is applied in the fields of heterogeneous catalyst chemical elements, chemical instruments and methods, physical/chemical process catalysts, etc. Small and other problems, to achieve the effect of large specific surface area, high oxygen evolution reaction activity, and increase of active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 LaNiO 3 Crystalline perovskite transforms into amorphous LaNiFe hydroxide

[0052] The specific preparation process of amorphous LaNiFe hydroxide is divided into two steps: LaNiO 3 Powder preparation, FeCl 3 Processing LaNiO 3 .

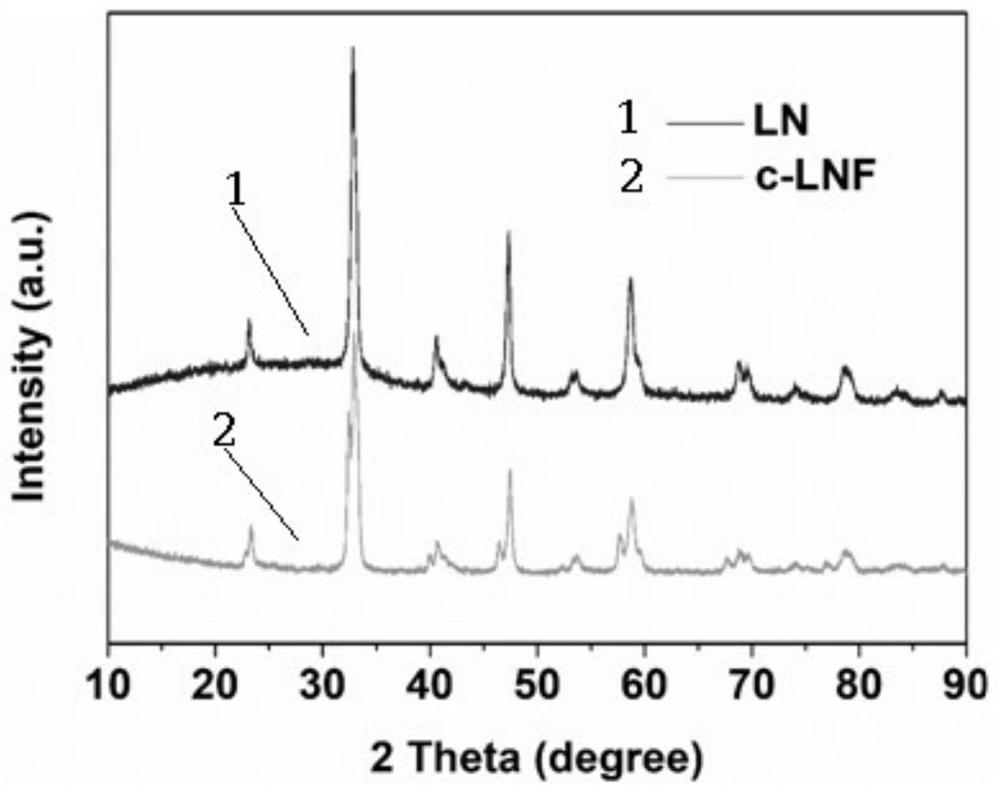

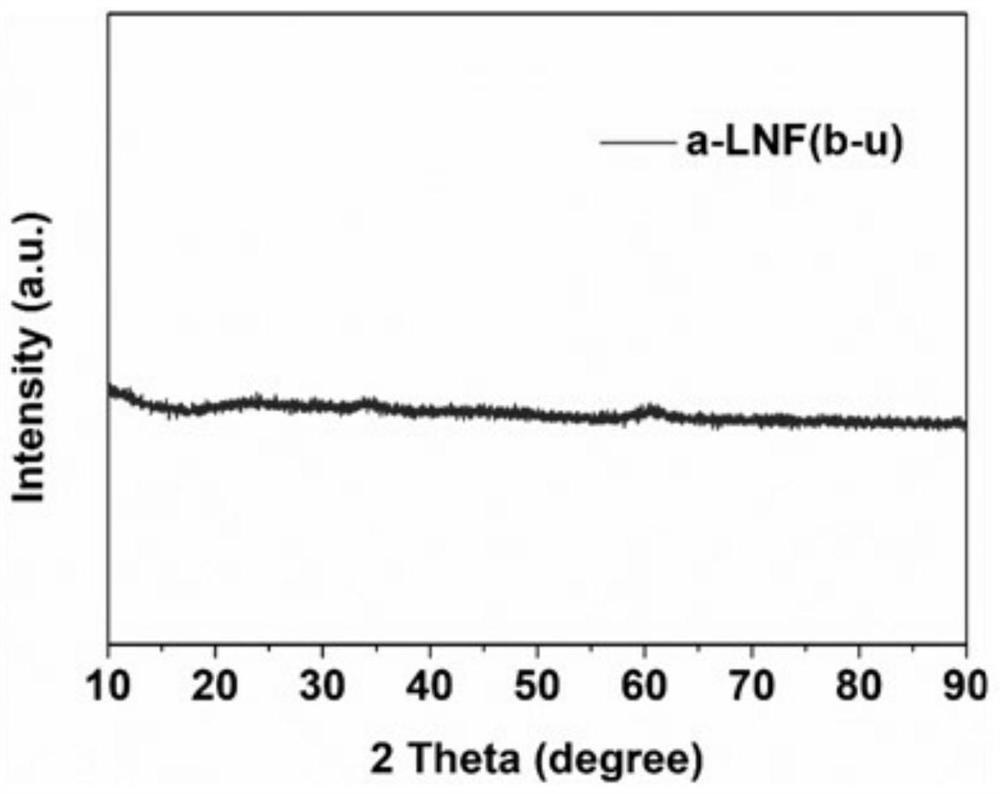

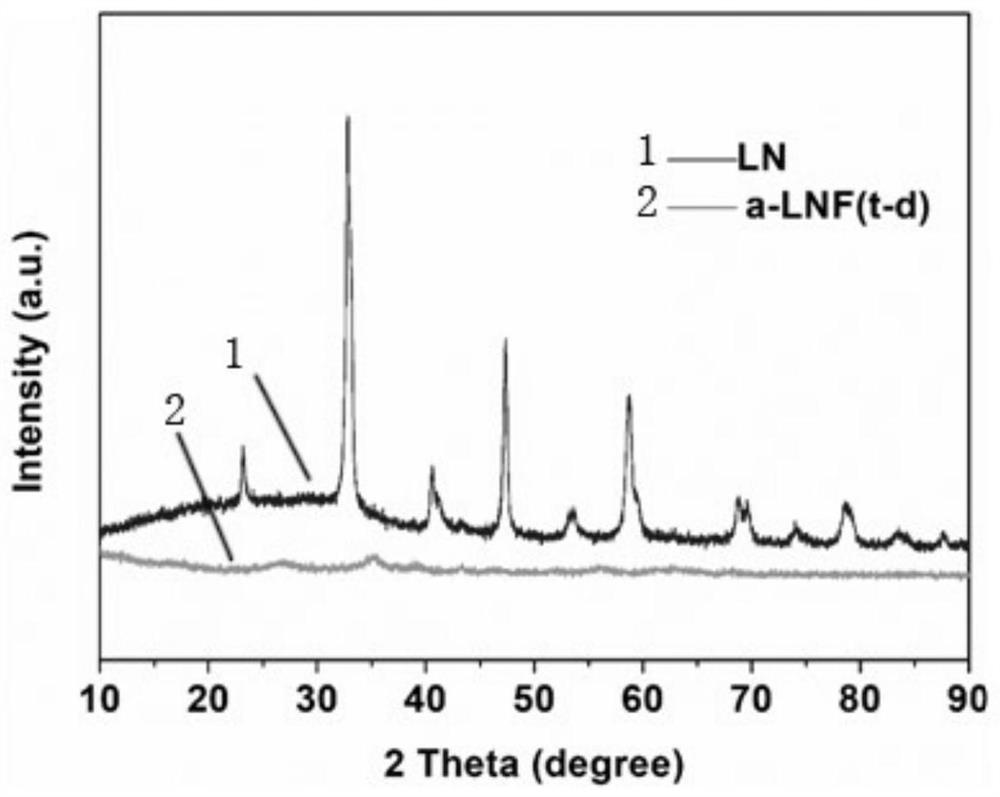

[0053] NeO 3 Preparation of powder: Weigh lanthanum oxide and nickel oxide with a La / Ni molar ratio of 1:1, use ethanol as solvent, and ball mill for one hour; after drying the slurry, put it in a muffle furnace and burn it at 850°C, keep it warm After ten hours, crystallized LaNiO 3 Perovskite powder, its X-ray diffraction curve is as follows image 3 shown;

[0054] FeCl 3 Processing LaNiO 3 : Weigh 1 g of crystallized LaNiO 3 powder, placed in a solution containing 1.5 g FeCl 3 in aqueous solution, sonicated for 2 hours. Use a high-speed centrifuge at a speed of 10,000 rpm, wash with deionized water three times repeatedly, and collect the product. Raw LaNiO 3 And the XRD picture of the product such as image 3 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com