Method for producing low-oxygen molybdenum-niobium alloy target material

A production method, molybdenum-niobium technology, applied in the field of production of low-oxygen molybdenum-niobium alloy sputtering targets, can solve problems such as limited, reduced oxygen content, and reduced processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

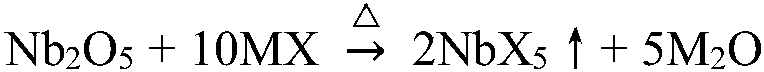

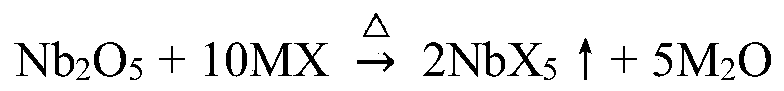

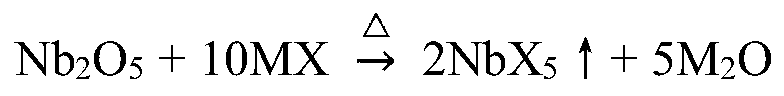

Method used

Image

Examples

Embodiment 1

[0050] The molybdenum powder with a particle size of 6.8 μm was placed in a vacuum furnace for pretreatment. The pretreatment temperature is 1200°C, and the pretreatment time is 3 hours. Take niobium hydride powder (oxygen content 2000ppm) with a particle size of 6-20 μm and mix it with potassium chloride, and then mix it with the pretreated molybdenum powder, wherein the weight ratio of Mo:NbH:KCl is 100:10:1, after 150 -250MPa cold isostatic pressing for 5-10 minutes to obtain a pressed ingot. The ingot is heat treated in a hydrogen vacuum dual-purpose furnace: firstly in a hydrogen atmosphere at 400-550°C for 2-5 hours, then raise the temperature to 650-800°C for 1-3 hours, then pump out the hydrogen, heat it at 1200-1450°C 1. Heat treatment for 3-4 hours under a vacuum pressure of 0.001-0.01Pa to obtain a molybdenum-niobium alloy ingot with a density of 70-80%. Then the alloy ingot is sintered by hot isostatic pressing at 100-200MPa and 1300-1450° C., and the holding tim...

Embodiment 2

[0052] The niobium powder (with an oxygen content of 1500ppm) having a particle size of 50-300 μm is mixed with sodium chloride having a mass fraction of 1.2-1.6%, and subjected to cold isostatic pressing at 150-250 MPa to obtain an ingot. The ingot is sintered in a vacuum hydrogen dual-purpose furnace. First, it is kept at 600-800°C for 3-5 hours under a hydrogen atmosphere, then the hydrogen is pumped out, and the temperature is raised to 1500-1700°C for 2-5 hours, and finally the temperature is raised to 1900- Insulate at 2100°C for 3-6 hours, keep the air pressure at 0.001-0.01Pa after vacuuming, and obtain a sintered niobium ingot with a density of 92-96% and an oxygen content of less than 200ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com