A resin-metal composite mirror grinding wheel based on sol-gel method and preparation method thereof

A sol-gel method, mirror grinding technology, applied in metal processing equipment, grinding/polishing equipment, grinding devices, etc. Uneven dispersion of powder molding, strong absorption capacity, and the effect of maintaining strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

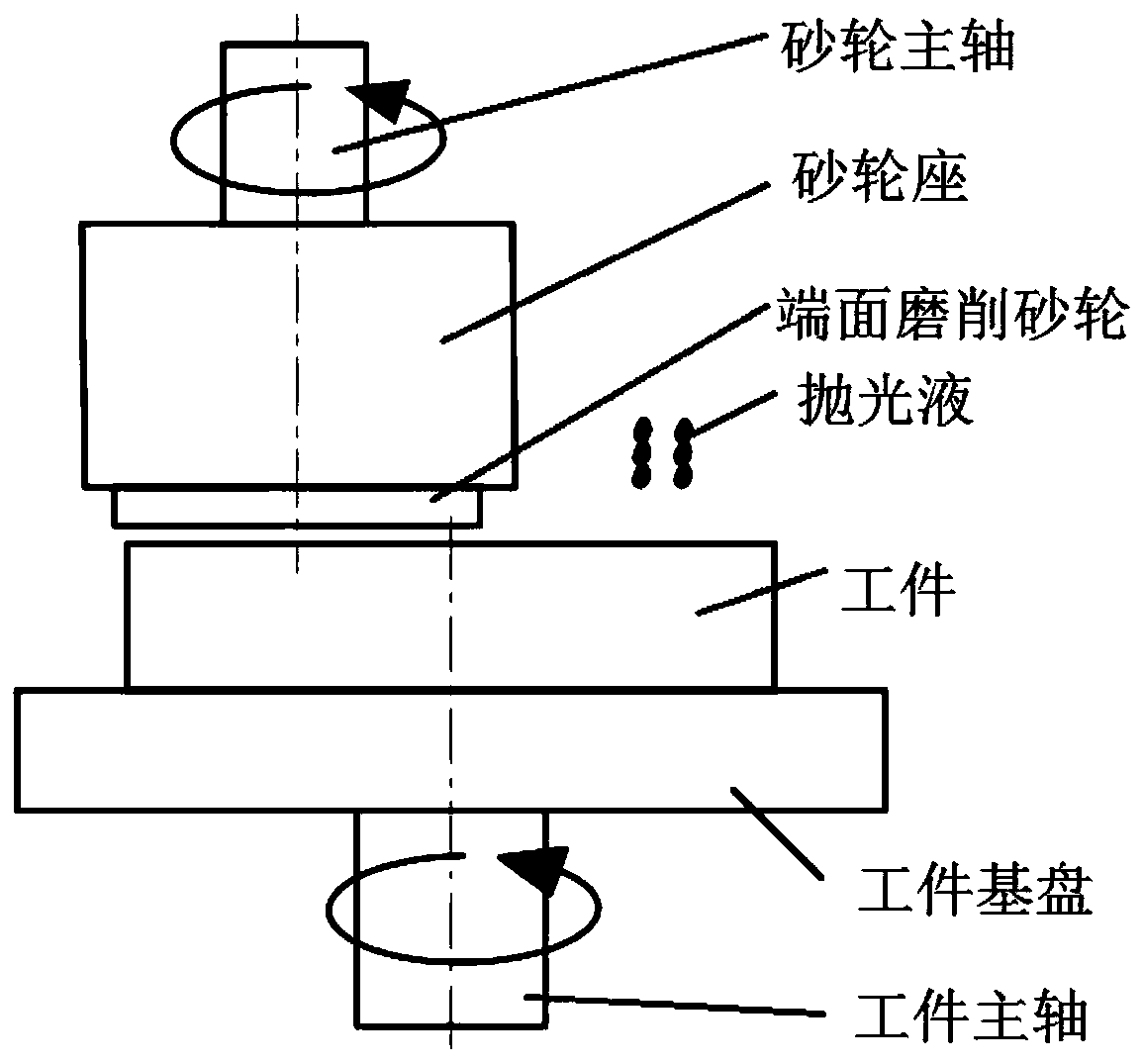

[0038] In this example, a mirror grinding wheel with fine pores was prepared, and a silicon plane lens was mirror-ground on an end grinder.

[0039] Step 1: Prepare aluminum nitride powder with a water-resistant film on the surface

[0040] By weight, mix 100g of aluminum nitride powder with an average particle size of 1 micron and 1kg of absolute ethanol, stir evenly, and heat up to 40°C in a water bath to obtain an ethanol dispersion of aluminum nitride; at the same time, dilute 600g of absolute ethanol 80g tetraethyl orthosilicate (TEOS), and 100g ammonia water diluted with 600g absolute ethanol and 100g water were added dropwise to the aluminum nitride ethanol dispersion, and the dropping rate was controlled at 2 drops / second. After reacting in a water bath for 6 hours, stop the reaction, vacuum filter, wash the product 3 times with absolute ethanol, then dry the obtained product at room temperature for 12 hours, and then calcinate at 300°C for 2 hours After cooling, pass...

Embodiment 2

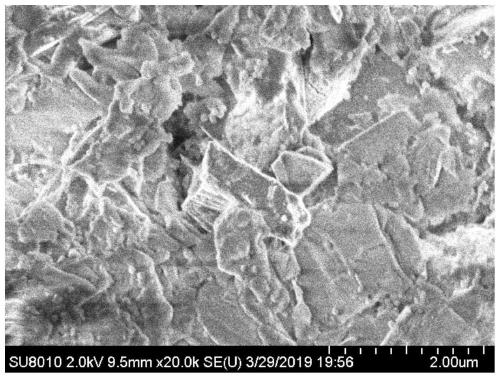

[0048] Polishing comparison test: using the traditional powder mixing-hot pressing method to prepare a mirror grinding wheel to grind the silicon flat lens, the surface morphology of the silicon flat lens obtained by grinding is as follows Figure 6 As shown, comparing the silicon plane lens surface topography and surface diagram of Example 1, the silicon plane lens surface obtained by polishing in Example 1 has even fine cuts, while the surface roughness of the silicon plane lens prepared by hot pressing method is It is 10.77nm, and the definition of mirror grinding is that the surface roughness after grinding is less than 10nm, so it is difficult to meet the requirements of mirror grinding. The uniform dispersion among materials of different densities is prone to agglomeration of powder particles when making fine-grained mirror grinding wheels.

[0049] At the same time, the durability comparison experiment of the gel grinding wheel and the hot-pressed grinding wheel was car...

Embodiment 3

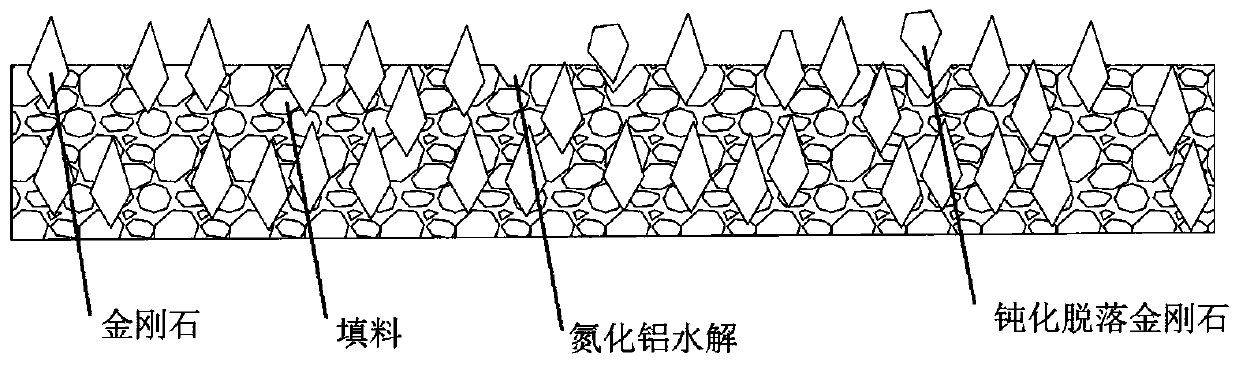

[0051] The mirror grinding emery wheel that embodiment 1 obtains is carried out grinding process in the grinding fluid of different pH value (7,8,9,10,11,12,13), sodium carbonate is as acid pH regulator, other grinding parameters Consistent, observe the wear rate of the abrasive tool, such as Figure 8 shown. It can be seen from the figure that as the pH value increases, the wear rate of the grinding wheel also increases. Therefore, considering the life of the grinding wheel, it is necessary to adjust the pH value and sharpen the grinding wheel according to the passivation degree of the grinding wheel during use. At the same time, the wear of the grinding wheel is controlled. For the aluminum nitride of the water-resistant coating in the emery wheel that embodiment 1 obtains, when the material removal rate is higher, the pH value of the grinding fluid can be controlled below 9, slowing down the wear of the emery wheel, and when the material removal rate declines, the Add sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com